Furnace Tapping Machine

+

We developed the discharge furnace robotic arm machine, based on the working process and tools of manual operation of slag port opening and closing of the copper smelting furnace. It has the function of a 7-axis linkage. Taking the horizontal centerline of the furnace as the reference, it can realize the horizontal movement of the whole machine, with the moving speed of 200 mm/s and the motor-driven by gear and rack.

Introduction of Furnace Tapping Machine

Automatic discharging furnace robotic arm is an equipment independently designed and developed by CIC for calcium carbide discharging characteristics by participating in calcium carbide production and closely focusing on the purpose of saving energy, reducing consumption, stabilizing production and reducing workers' labor intensity.

As a high-temperature production industry, calcium carbide workers in front of the furnace will face many high-temperature hazards in the process of calcium carbide discharging. Out of our understanding of the process of calcium carbide discharging, we have designed a remote control system for the high magnetic field environment in front of the calcium carbide furnace. The discharging workers can stay away from the high-temperature discharging area and effectively avoid the production threat. The fully Automatic discharging furnace robotic arm developed by CIC is a truly unattended tapping operation, which truly realizes the original intention and aim of "emancipating employees from the environment of high temperature, high risk, strong physical strength and high dust".

Specification of Furnace Tapping Machine

- ° Rotation, rotation speed 10°/s. Worm gear transmission is adopted.

- °, Elevation 3 °, Depression angle 18 °, Swing speed 5 °/s. Hydraulic cylinder drive.

- ², Max 110kgf/cm², 18.5kw × 2 ( One of them is standby). Proportional valve control is adopted.

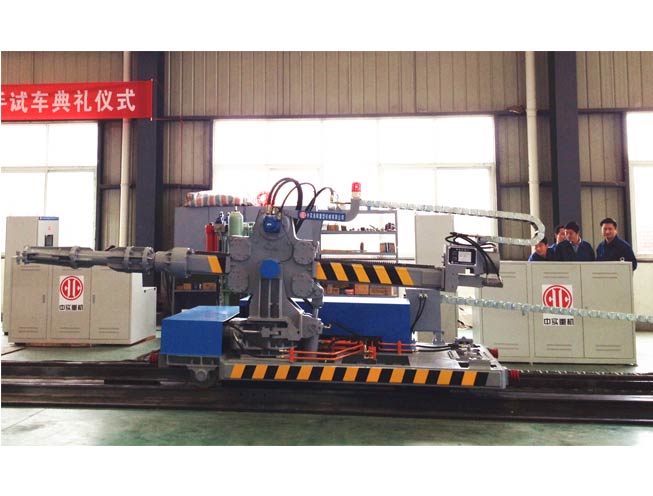

Discharge Furnace Robotic Arm Trial Run In The Factory

Trial run in the factory

Discharge Furnace Robotic Arm Central Control Operation Area

Central control operation area

Discharge Furnace Robotic Arm Package

Package & Delivery

Advantages of Furnace Tapping Machine

The furnace tapping machine has the functions of opening, pulling and plugging. It reduces the labor force in front of the furnace and reduces the potential safety hazards of employees working in front of the furnace. Availbale for copper mining process.

Save consumables and completely cancel the oxygen blowing operation mode.

The equipment has the function of impact opening, and the impact frequency is high. Under the condition of maintaining the furnace hole, the furnace hole can be opened easily.

The drill rod used for eye pulling of the equipment is 50mm round steel. The flow of calcium carbide brought out is large, the tapping time is shortened, the heat loss of calcium carbide furnace is small, and the power consumption is saved.

As one of heavy equipment manufacturers, we can offer different kinds of related products for sale, if you have needs, please contact us.

If you want to know more types of sludge dewatering centrifuge, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm, the rotor body (including the blade), transmissi... | |

| Industrial Grinding Mill Machine | Independent design and manufacture can be achieved according to customer demand and different working conditions. CIC grinding machine suppliers us... | |

| SAG Mill | Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and scre... | |

| Girth Gear | CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VO... | |

| Furnace Tapping Machine | We developed the discharge furnace robotic arm, based on the working process and tools of manual operation of slag port opening and closing of the ... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |