Girth Gear

CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VOD refining furnace, etc. As professional girth gear manufacturer , we can pour 350t liquid steel one time and yields more than 200,000t of high-quality liquid steel and can produce the high-quality steel of more than 260 steel grades such as carbon steel, structural alloy steel and the structural steel, refractory steel and stainless steel of special requirement. The maximum weight of casting, gray casting, graphite cast iron and non-ferrous casting is 200t, 30t, 20t and 205t separately.

Feature of Girth Gear

Module Range: 10 Module to 70 Module.

Diameter: Min 800mm to 16000 mm.

Weight: Max 120 MT single piece.

Three Different Girth Gear Designs: Fabricated steel - forged ring - rolled plate

Standards/Certificates: • UNI EN ISO • AWS • ASTM • ASME • DI

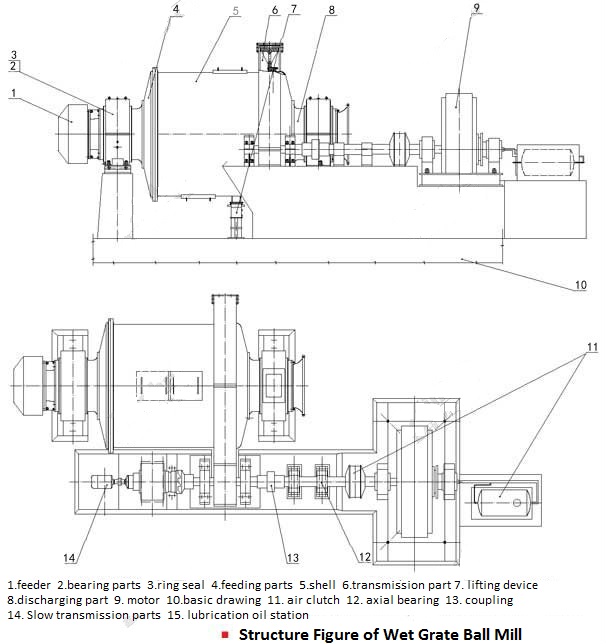

Professional rotary kiln girth gear and

ball mill girth gearmanufacturers.

Our Advantages of Girth Gear

Products with Customers' Designs

Strong Machining & Heat Treatment Abilities

Strict Quality Control

Prompt Delivery

Experience in Cooperation with Fortune 500 Companies

Process of Grith Gear

Forging or Casting

Normalizing & Tempering-Proof Machining

Quenching & Tempering

Finish Machining (Teeth Grinding)

Technical Parameter of Grith Gear

|

Item |

Description |

|

|

1 |

Diameter |

≤15m |

|

2 |

Module |

≤45 |

|

3 |

Material |

Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel |

|

4 |

Structure From |

Integrated, Half to Half, Four Pieces and More Pieces |

|

5 |

Heat Treatment |

Quenching & Tempering, Normalizing & Tempering, Carburizing & Quenching & Tempering |

|

6 |

Tooth Form |

Annular Gear, Outer Gear Ring |

|

7 |

Standard |

ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

InspectionandTestOutlineofGirthGear

|

Item |

Inspection Area |

Acceptance Criteria |

Inspection Stage |

Certificates |

|

|

1 |

ChemicalComposition |

Sample |

Material Requirement |

When SmeltingAfter Heat Treatment |

Chemical CompositionReport |

|

2 |

MechanicalProperties |

Sample (Test Bar on the Gear Body) |

Technical Requirement |

After Heat Treatment |

Mechanical PropertiesReport |

|

3 |

HeatTreatment |

Whole Body |

Manufacturing Standard |

During Heat Treatment |

Heat Treatment ReportCurves of HeatTreatment |

|

4 |

HardnessTest |

Tooth Surface, 3 Points Per 90° |

Technical Requirement |

After Heat Treatment |

Hardness Teat Report |

|

After Semi FinishMachining |

|||||

|

5 |

DimensionInspection |

Whole Body |

Drawing |

After Semi FinishMachining |

Dimension InspectionReport |

|

Finish Machining |

|||||

|

6 |

Magnetic Power Test (MT) |

Tooth Surface |

Agreed Standard |

After Finish GearHobbing |

MT Report |

|

7 |

UT |

Spokes Parts |

Agreed Standard |

After Rough Machining |

UT Report |

|

After Welded |

|||||

|

After Semi FinishMachining |

|||||

|

8 |

PT |

Defect Area |

No Defect Indicated |

After DiggingAfter Welded |

PT Record |

|

9 |

Mark Inspection |

Whole Body |

Manufacturing Standard |

Final Inspection |

Pictures |

|

10 |

AppearanceInspection |

Whole Body |

CIC's Requirement |

Before Packing(Final Inspection) |

|

|

11 |

Anti-rustInspection |

Whole Body |

Agreed Anti-rust Agent |

Before Packing |

Pictures |

|

12 |

PackingInspection |

Whole Body |

Agreed Packing Form |

During Packing |

Pictures |

Part Reference List of Girth Gear

|

Material |

OD/mm |

Module |

Application |

Client |

|

|

1 |

T30MoCrNi14 |

10394 |

28 |

SAG |

Romania |

|

2 |

T30MoCrNi14 |

8356 |

28 |

Ball Mill |

|

|

3 |

G35CrNiMo6-6 |

5910 |

39 |

Rotary Kiln |

KHD |

|

4 |

G34CrMo4 |

6180 |

30 |

Cement Mill |

|

|

5 |

G35CrNiMo6-6 |

6362 |

42 |

Rotary Kiln |

|

|

6 |

G35CrNiMo6-6 |

6362 |

42 |

Rotary Kiln |

|

|

7 |

G34CrMo4 |

5909 |

39 |

Rotary Kiln |

|

|

8 |

G34CrMo4 |

6362 |

42 |

Rotary Kiln |

|

|

9 |

G34CrMo4 |

6621 |

39 |

Rotary Kiln |

|

|

10 |

ZG 35CrNiMo |

5452 |

45 |

Rotary Kiln |

Tunisia |

|

11 |

ZG 35CrMo |

4868 |

22 |

Cement Mill |

|

|

12 |

G34CrMo4 |

42 |

Cement Rotary Kiln |

Giant→KHD |

|

|

13 |

G35CrNiMo6-6 |

7369 |

45 |

Cement Rotary Kiln |

|

|

14 |

G34CrMo4 |

5964 |

42 |

Cement Rotary Kiln |

|

|

15 |

ASTM 4140 |

7289 |

/ |

American Rexnord |

|

|

16 |

ZG42CrMo |

6972 |

25 |

Cement Rotary Kiln |

Hong Kong |

|

17 |

ZG42CrMo |

3400 |

25 |

Sugar Dryer |

Japan TSK |

|

18 |

ZG42CrMo |

3480 |

20 |

Sugar Dryer |

|

|

19 |

ZG310-570 |

3360 |

20 |

Fertilizer Dryer |

Malaysia |

|

20 |

ZG310-570 |

3640 |

20 |

Fertilizer granulator |

|

|

21 |

ZG42CrMo |

4100 |

32 |

Fertilizer Cooler |

|

|

22 |

ZG42CrMo |

5550 |

25 |

Fertilizer Dryer |

|

|

23 |

ZG42CrMo |

3040 |

20 |

Fertilizer granulator |

|

|

24 |

GS35CrMoV |

7318 |

/ |

Venezuela |

|

|

25 |

ASTM 4140 |

7560 |

40 |

Dryer |

|

|

26 |

ZG42CrMo |

6633 |

Rotary Kiln |

Korea |

|

|

27 |

ZG42CrMo |

5688 |

36 |

PTA Dryer |

Japan TSK |

As one of heavy equipment suppliers, we can offer different kinds of related products for sale, if you have needs, please contact us.

If you want to know more details of ball mill mining, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Overflow Ball Mill | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Wet Grid Ball Mill | Wet ball mill is a kind of energy-saving industrial ball mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill proc... | |

| Furnace Robotic Arm Machine | With the development of modern science and technology, industrial arm is a kind of high-tech automatic intelligent mechanical production equipment ... | |

| Furnace Tap Hole Machine | The manipulator is applied to the opening and plugging of the slag port in a copper smelting furnace. According to the copper smelting furnace slag... | |

| Overflow Ball Mill | n recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis t... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |