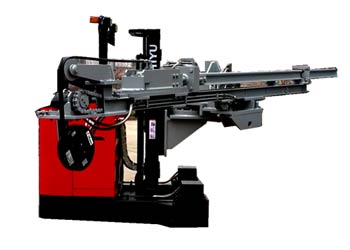

Overflow Ball Mill

CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold directly to end customers, business partners, and EPC projects. As a professional heavy equipment companies, CIC serves multiple roles, such as, cement machinery suppliers, mining machinery manufacturers, grinding mill manufacturer, rotary kiln manufacturer, rotary dryer manufacturer, sludge dryer manufacturer and so on.

In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow ball millis the most widely used equipment in wet grinding. Overflow type ball millis mainly used for wet grinding of all kinds of ores. In the grinding process, raw materials and water are added at the same time to make the ground fine materials form pulp with water, which is discharged in the way of self flow, so as to complete the grinding operation, so it is called overflow ball mill.

Features of Overflow Ball Mill

lEasy to start, stable operation

lSimple structure, convenient maintenance

lVarious working modes and optional granularity

lThe grinding time is short and the service life is long

Application of Overflow Ball Mill

Overflow ball mill is often used for grinding fine ore or regrinding concentrate in mineral processing industry. In addition, it can also be used in silicate products, building materials, chemical fertilizers, non-ferrous metals, glass ceramics and other production industries.

Working Principle of Overflow Ball Mill

When overflow ball mill is working, raw materials and water are continuously added from one port, and the slurry is formed after being ground by steel ball inside the cylinder. After the slurry is ground to the target size and accumulated to a certain height, it will overflow from the other end.

Advantages of Overflow Ball Mill

lRich Experience: We have produced hundreds of overflow ball mill typesevery year. We ensure the quality and provide after-sales service. The product has a long service life.

lStrong Production Capacity: We can make quick delivery with our 6 factories and 800+ workers.

lReasonable Price: we have long-term cooperation with hundreds of suppliers, and will lower the cost of raw materials and processing.

Intelligent Grinding Expert System-Ball Mill

To realize the intelligent control for cement ball milloperation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient. Learn More...

Technical Properties List of Overflow Ball Mill

|

Specification |

Shell Diameter |

Shell Length |

Volume |

Rotary Speed |

Grinding Medium Load |

Transmission Type |

Motor |

Profile Dimensions |

Total Weight |

Remarks |

|

|

mm |

mm |

M3 |

r/min |

t |

Power(kw) |

Rotary Speed(r/min) |

(L×W×H)m |

t |

|||

|

MQY15×30 |

1500 |

3000 |

5 |

9 |

Side-edge Transmission |

95 |

742 |

Drum Feeder |

|||

|

MQY15×36 |

1500 |

3600 |

95 |

742 |

Rubber Liners |

||||||

|

MQY18×61 |

1830 |

6100 |

220 |

736 |

|||||||

|

MQY21×30 |

2100 |

3000 |

15 |

200 |

740 |

45 |

|||||

|

MQY24×30 |

2400 |

3000 |

21 |

250 |

980 |

55 |

|||||

|

MQY24×70 |

2400 |

7000 |

21 |

48 |

475 |

740 |

67 |

Rubber Liners |

|||

|

MQY27×36 |

2700 |

3600 |

39 |

400 |

|||||||

|

MQY27×40 |

2700 |

4000 |

38 |

400 |

70 |

||||||

|

MQY27×45 |

2700 |

4500 |

500 |

76 |

|||||||

|

MQY27×40 |

2700 |

4000 |

53 |

630 |

589 |

Rubber Liners |

|||||

|

MQY28×54 |

2800 |

5400 |

30 |

630 |

167 |

13×5.83×4.7 |

|||||

|

MQY28×80 |

2800 |

8000 |

43 |

20 |

800 |

137 |

115 |

For coal water slurry |

|||

|

MQY30×110 |

3000 |

11000 |

100 |

Central Transmission |

1250 |

429 |

|||||

|

MQY32×36 |

3200 |

3600 |

Side-edge Transmission |

500 |

167 |

||||||

|

MQY32×40 |

3200 |

4000 |

60 |

560 |

980 |

||||||

|

MQY32×45 |

3200 |

4500 |

630 |

167 |

13×7.0×5.82 |

||||||

|

MQY32×54 |

3200 |

5400 |

73 |

800 |

167 |

129 |

|||||

|

MQY32×64 |

3200 |

6400 |

86 |

1000 |

167 |

140 |

|||||

|

MQY32×75 |

3200 |

7500 |

102 |

1250 |

734 |

154 |

|||||

|

MQY32×90 |

3200 |

9000 |

1250 |

150 |

173 |

||||||

|

MQY34×45 |

3400 |

4500 |

37 |

800 |

167 |

||||||

|

MQY34×56 |

3400 |

5600 |

1120 |

985 |

|||||||

|

MQY36×45 |

3600 |

4500 |

76 |

1000 |

167 |

13×7.3×6.3 |

|||||

|

MQY36×50 |

3600 |

5000 |

1250 |

167 |

15×7.6×6.2 |

150 |

|||||

|

MQY36×50 |

3600 |

5000 |

Central Transmission |

1250 |

429 |

23×4.6×6.3 |

176 |

||||

|

MQY36×56 |

3600 |

5600 |

Side-edge Transmission |

1250 |

750 |

||||||

|

MQY36×60 |

3600 |

6000 |

Central Transmission |

1250 |

429 |

24×4.6×6.3 |

|||||

|

MQY36×60 |

3600 |

6000 |

54 |

102 |

Side-edge Transmission |

1250 |

167 |

||||

|

MQY36×61 |

3600 |

6100 |

1200 |

980 |

|||||||

|

MQY36×85 |

3600 |

8500 |

79 |

131 |

1800 |

743 |

20×8.2×7.1 |

||||

|

MQY36×90 |

3600 |

9000 |

138 |

Central Transmission |

1800 |

743 |

28×4.6×5.6 |

286 |

|||

|

MQY38×67 |

3800 |

6700 |

70 |

130 |

Side-edge Transmission |

1400 |

743 |

19×8.2×7.1 |

|||

|

MQY40×60 |

4000 |

6000 |

16 |

126 |

1500 |

200 |

|||||

|

MQY40×67 |

4000 |

6700 |

16 |

1600 |

200 |

||||||

|

MQY40×135 |

4000 |

13500 |

155 |

16 |

233 |

3300 |

200 |

23×10×4.9 |

343 |

For coal water slurry |

|

|

MQY43×61 |

4300 |

6100 |

80 |

144 |

1750 |

200 |

14×10×7.7 |

||||

|

MQY50×64 |

5030 |

6408 |

120 |

251 |

2600 |

200 |

|||||

|

MQY50×83 |

5030 |

8300 |

266 |

3300 |

200 |

22×10.5×9 |

|||||

|

MQY55×65 |

5500 |

6500 |

264 |

3400 |

200 |

||||||

|

MQY55×85 |

5500 |

8500 |

335 |

4500 |

200 |

||||||

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Overflow Ball Mill | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Industrial Rotary Dryer Machine | CIC have accumulated decades of experience in the production of industrial sludge dryermachine, through continuous improvement, research and develo... | |

| SAG Mill | Semi autogenous millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screen... | |

| Furnace Robotic Arm Machine | With the development of modern science and technology, industrial arm is a kind of high-tech automatic intelligent mechanical production equipment ... | |

| Industrial Centrifuge Machine | Centrifugal concentrator is a kind of equipment for gravity separation of ore particles in a centrifugal force field, which is one of the high-effi... |

Похожие товары

| YC160W Wheel excavator YC160W | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |