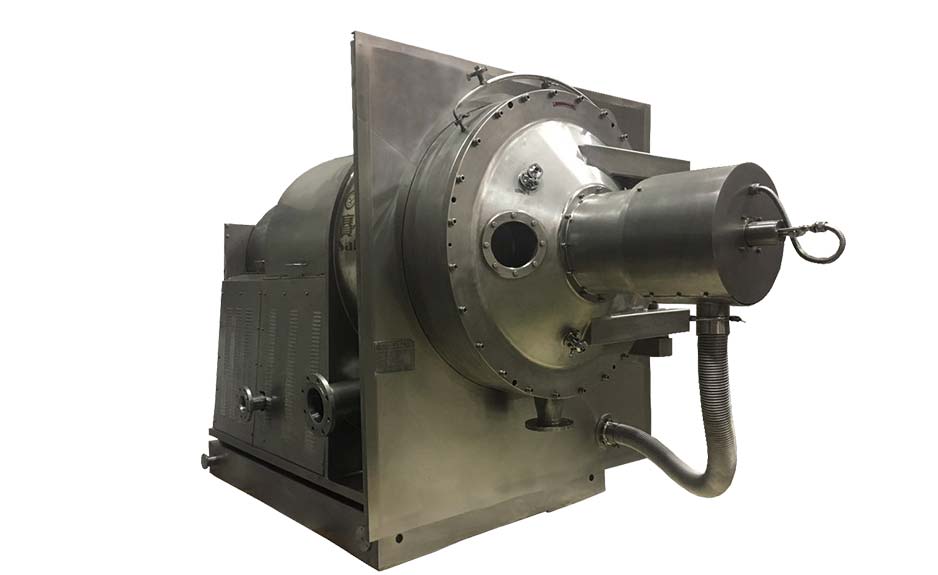

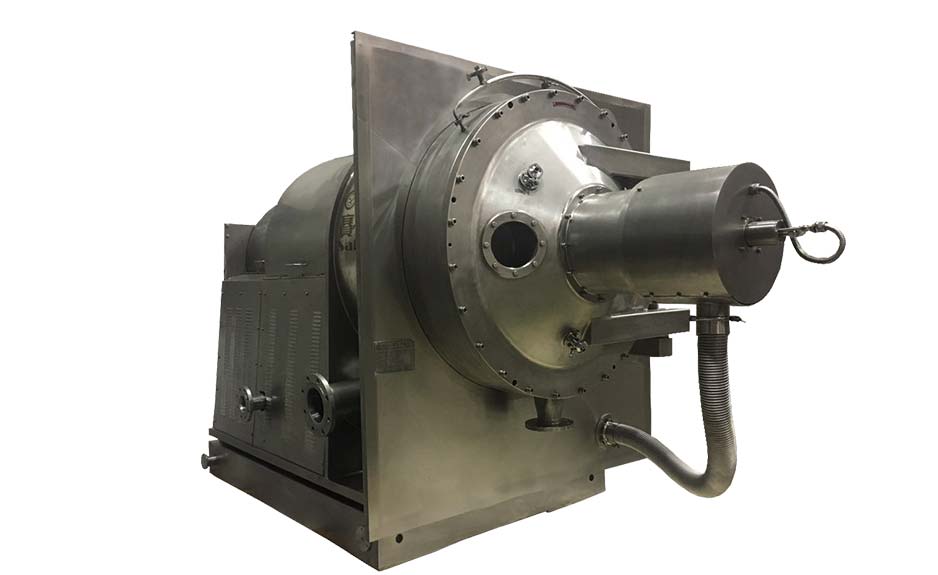

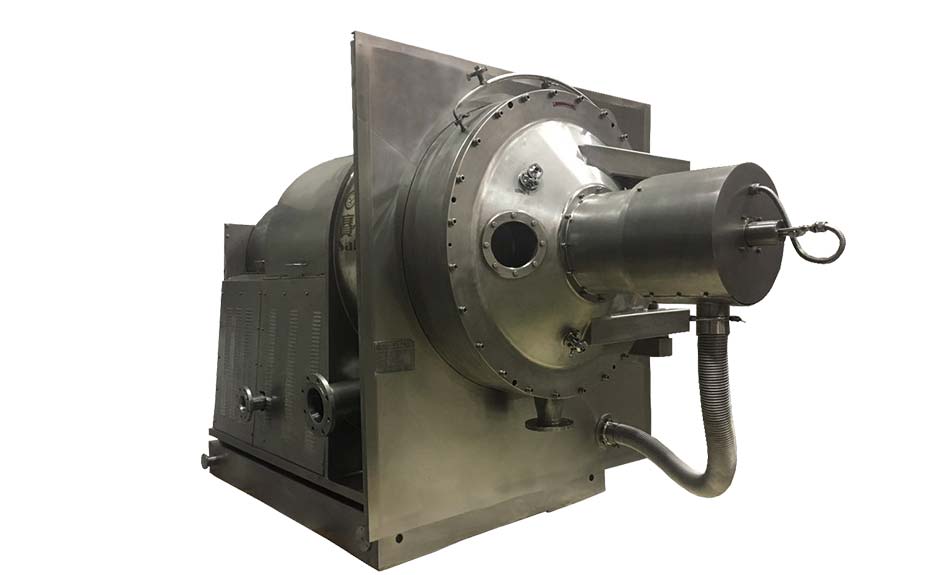

FSD CENTRIFUGAL DRYER

This centrifugal drying machine integrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suitable on high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in a sterile environment, and products sensitive to oxygen.

FSD CENTRIFUGAL DRYER SPECIFICATION

FSD Centrifuge Dryer Main Parameters

Standard Model FSD-400 FSD-600 FSD-800 FSD-1000 FSD-1300

Drum diameter (mm) 400 600 800 1000 1300

Max. Filling volume (L) 20 63 125 235 800

Filter area (m2) 0.38 0.85 1.26 1.89 2.4

Rotating speed (r/min) 1640 1340 1160 1040 900

Separating factor (N) 601 602 602 605 600

Length×Width×Height 3200×1400

×1700 3400×1600

×1900 3900×1800

×2400 4000×1800

×2500 5600×2000

×2800

Weight (Kg) 3500 4300 9500 11500 20500

FSD CENTRIFUGAL DRYER MACHINE WORKING PROCESS

The suspension will enter into the rotating drum through the feeding pipe and the whole procedure will be monitored. The suspension will form a filter cake on the filter cloth and the mother liquid will be drained through the filter cloth. As the industrial centrifugal dryer, the filter cake will have an even structure. Usually, the filter cake will be washed after feeding. Under high speed centrifugal separation, mother liquid and washing liquid will be drained and the speed can be adjusted according to the material. After drying, the reduction of the speed will cause the collapse of the filter cake and form particles. The residual materials on the filter cloth can be removed by blowing from the nozzle. After all these, solid will be discharged.

FSD DRYING CENTRIFUGEFEATURES

Multifunction

Enclosed and whole sealing process space

Full automatic and high effective CIP system

High effective back flush drying

Components adopt standard module which is convenient for upgrade

Vacuum drying

Flexible process control

Sampling from whole sealing process space

Inspect process area

Full process inspection of material temperature

As one of the most professional centrifuge machine manufacturers, Saideli provides solid solid separation equipment, centrifuge separator machineand etc. Want to know more, contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| INDUSTRIAL CENTRIFUGE MANUFACTURER | Saidelicentrifuge can be separated into lab centrifuge and industrial centrifuge machine with a larger model. And has been widely used in many indu... | |

| FW INVERTING CENTRIFUGE | When the drum is under high-speed operation, the suspension enters the drum through the feeding pipe. Under the action of centrifugal force, the su... | |

| FSD CENTRIFUGAL DRYER | This drying centrifugemachine integrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suita... | |

| FSD CENTRIFUGAL DRYER | This centrifugal drying machineintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suit... | |

| LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE | LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE L(P)LGZ vertical basket centrifuges are suitable for solid-liquid separation of fibroid products... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |