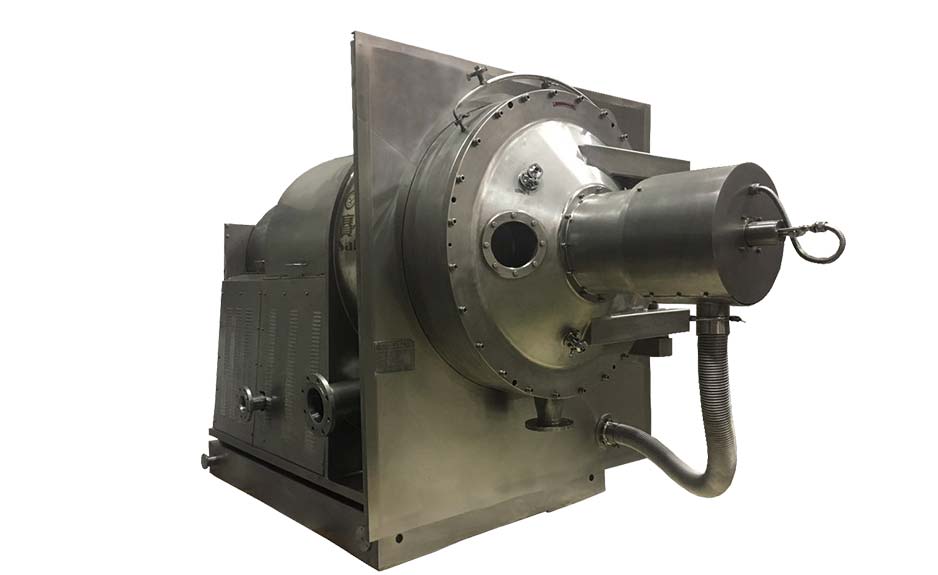

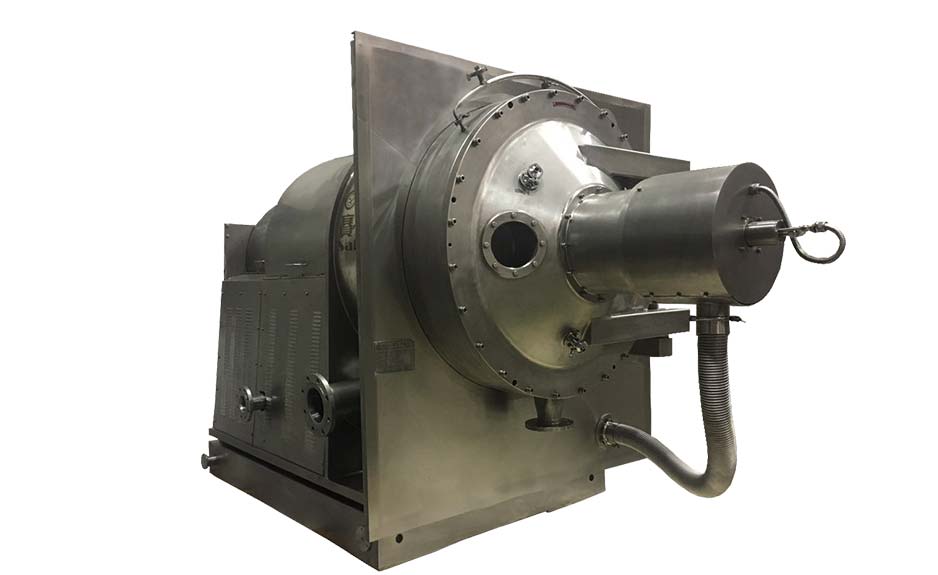

FSD CENTRIFUGAL DRYER

This centrifugal drying machine integrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suitable on high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in a sterile environment, and products sensitive to oxygen.

FSD CENTRIFUGAL DRYER SPECIFICATION

FSD Centrifuge Dryer Main Parameters

Standard Model FSD-400 FSD-600 FSD-800 FSD-1000 FSD-1300

Drum diameter (mm) 400 600 800 1000 1300

Max. Filling volume (L) 20 63 125 235 800

Filter area (m2) 0.38 0.85 1.26 1.89 2.4

Rotating speed (r/min) 1640 1340 1160 1040 900

Separating factor (N) 601 602 602 605 600

Length×Width×Height 3200×1400

×1700 3400×1600

×1900 3900×1800

×2400 4000×1800

×2500 5600×2000

×2800

Weight (Kg) 3500 4300 9500 11500 20500

FSD CENTRIFUGAL DRYER MACHINE WORKING PROCESS

The suspension will enter into the rotating drum through the feeding pipe and the whole procedure will be monitored. The suspension will form a filter cake on the filter cloth and the mother liquid will be drained through the filter cloth. As the industrial centrifugal dryer, the filter cake will have an even structure. Usually, the filter cake will be washed after feeding. Under high speed centrifugal separation, mother liquid and washing liquid will be drained and the speed can be adjusted according to the material. After drying, the reduction of the speed will cause the collapse of the filter cake and form particles. The residual materials on the filter cloth can be removed by blowing from the nozzle. After all these, solid will be discharged.

FSD DRYING CENTRIFUGEFEATURES

Multifunction

Enclosed and whole sealing process space

Full automatic and high effective CIP system

High effective back flush drying

Components adopt standard module which is convenient for upgrade

Vacuum drying

Flexible process control

Sampling from whole sealing process space

Inspect process area

Full process inspection of material temperature

As one of the most professional centrifuge machine manufacturers, Saideli provides solid solid separation equipment, centrifuge separator machineand etc. Want to know more, contact us.

Send product request

Other supplier products

| FSD CENTRIFUGAL DRYER | This drying centrifugemachine integrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suita... | |

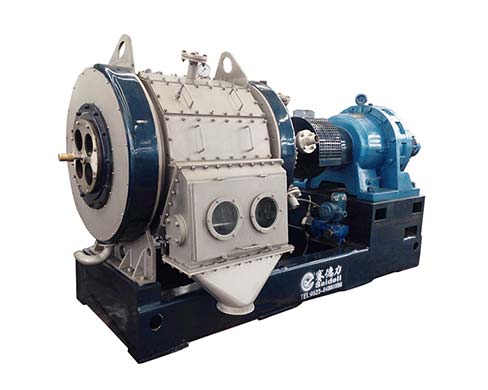

| HR PISTONS PUSHING CENTRIFUGE | When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher centrifuge will be led to th... | |

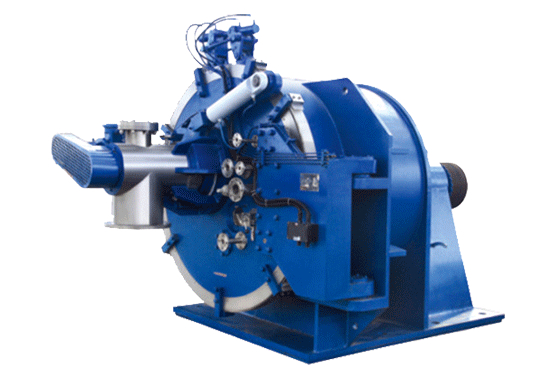

| INDUSTRIAL FILTER | Industrial centrifugal filteris the pressurization rotary drum filter, integrating washing, extracting, evaporating, and drying is a piece of close... | |

| SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER | Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial c... | |

| INDUSTRIAL CENTRIFUGE MANUFACTURER | Saidelicentrifuge can be separated into lab centrifuge and industrial centrifuge machine with a larger model. And has been widely used in many indu... |

Same products

| YC160W Wheel excavator YC160W | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |