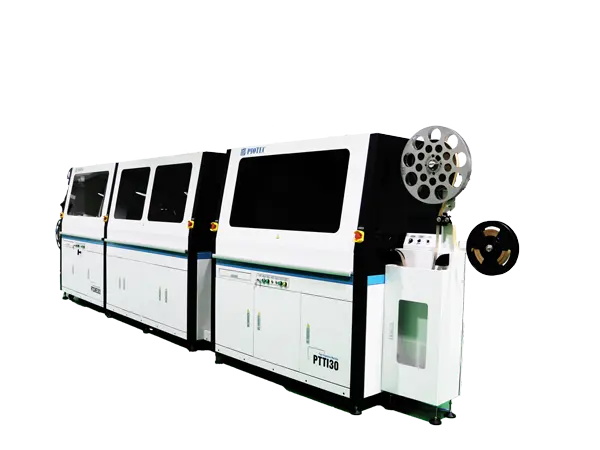

PTCME302 Chip Module Encapsulation Machine

PTCME302 represents a new generation of high-speed smart card module adhesive packaging, packaging thickness measurement, and packaging appearance inspection system.

100% online control of the entire process, minimizing manual intervention and saving labor costs.

The latest gluing program design of the 16 nozzle gluing head makes the gluing quality higher, easier to maintain, and thus achieves simpler operations. Compared with traditional UV gas discharge lamps, the curing unit configuration of PTCME302 significantly reduces the space occupied by the LED UV lamp, while increasing its power, resulting in higher production efficiency.

To save factory labor costs and effectively control product quality, PTCME302 is equipped with module packaging thickness detection units and module strip surface defect detection units.

Specifications of PTCME302-Chip Module Encapsulation Machine

PARAMETER

|

Capacity |

Full fill: 33000UPH; Dam filling: 23000UPH |

|

Dimension |

7300mm×1200mm×2000mm |

|

Weight |

2100Kg |

|

Power Supply |

220V(-5%~+10%), 50Hz, 8KW |

|

Air Supply |

Pressure: 0.6Mpa; Flow rate: 1500LPM |

|

Noise |

≤65dB |

|

Operation Temperature |

Room temperature: 23℃±3℃ |

|

Operation Humidity |

50±10% |

Functions of PTCME302-Chip Module Encapsulation Machine

PARAMETER

Issuing/receiving Unit

- φ 40mm (without keyway), outer diameter φ 500mm material tray.

- φ P40mm (without keyway), outer diameter φ 500mm protective belt material tray.

Stripe Drive Unit

- ≤ ± 0.1mm.

Feed Detection Unit

Gluing Unit

3 Applicable types of glue include: dam building glue and filling glue.

- ≤ ± 0.1mm and a sealing thickness accuracy of ≤ ± 0.03mm.

Visual Positioning Unit

- ≤ ± 0.1mm.

UV Curing Unit

- °, making it convenient for U replacement or maintenance.

Thickness Measuring Unit

Gun Waste Unit

- Use the chasing gun waste mode, with a diameter of 2 ± 0.1mm and a positional error of ≤ ± 0.2mm.

Advantages of PTCME302-Chip Module Encapsulation Machine

WHY

01

Real time monitoring of adhesive coating effect and packaging thickness.

02

Visual adhesive trajectory design allows for easy creation of adhesive paths.

03

Glue coating accuracy ± 30um Damming and filling or double filling production mode.

04

Fully automatic X/Y direction adjustable gun waste hole function detailed production data report.

05

Optional visual defect detection function.

Now the id card making machine priceis reasonable, if you have needs to buy identity card making machine, please contact us.

If you want to know more smart chip card solutions, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| FPL6052 Banking Card Flexible Perso Line | The Piotec FPL series products are personalized production solutions tailored to the mass production needs of bank card manufacturers. This prod... | |

| Piotec Smart Card Making Machine | The equipment contains a number of independent research and development of core advantages of technology (whole machine research and development ca... | |

| M2M Semiconductor Chip Personalization Machine | Machine-to-Machine (M2M) semiconductor chip making equipmentare specialized devices used in the production and personalization of M2M chips. These ... | |

| SCM200 M2M Chip Personalization Machine | The SCM200 M2M chip personalization data writing machine can perform electrical performance testing, personalized data writing, and surface laser... | |

| Smart Card Personalization and Issuing Machine | To meet high-volumn personalization production for SIM card with multi-chips, PTA-8500A was developed and put into the market in 2015. The PTA-8500... |