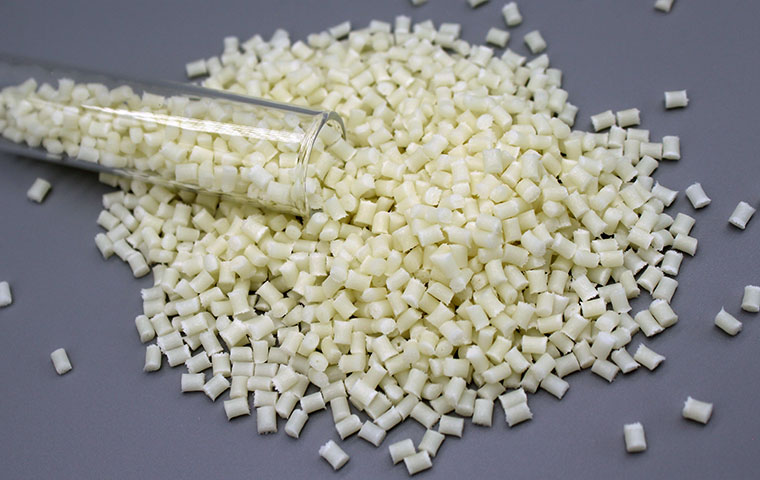

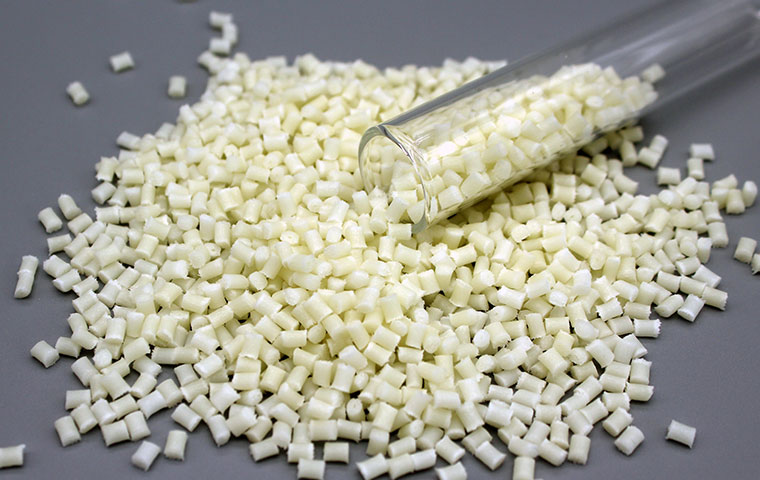

PA66 GF20 Halogenated FR (A2014D, A2114D) for Engineering Plastics

Nylon 66, filled with 20% of glass fiber and flame resistance halogens, are extruded by Coperion twin-screw extruder is PA66 GF20halogenated FR.

Typical Application of AnmeiPA66 GF20 Halogenated FR (A2014D) (A2015D)

PA66 20% glass fiber and halogenated flame resistance mixed modified grades are very popular to the sectors of highly demanding flame-retardant structural parts, meeting the characteristics of injection molding grade, reinforced grade and flame retardant grade.

The advantage of halogenated FR is low price, good stability, less additive, good compatibility with synthetic resin materials.

Processing Detail of PAGF20Halogenated FR (A2014D)

Other Details of PA66 GF20 Halogenated FR (A2014D)

|

Physical Property |

|

|

Ash |

(20.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1530Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.4-0.6 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.8-1.2% I ISO294-4) |

|

Mechanical Properties |

|

|

Tensile strength (105.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/ min |

|

Notched Impact Strength (10.0 KJ/m2 I ISO179) Conditioned |

|

|

Flexural Strength (177MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (5050 MPa I ISO178) Conditioned |

2mm/min |

|

Thermal Property |

|

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(245*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

|

|

Injection Molding Conditions |

|

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions are just for reference, please make an adjustment based on the actual situation!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This type of polyamide PA66 contains stabilization and i... | |

| PA6 GF45 (A1011I) for Engineering Plastics | Polyamide 6 reinforced with 45% Glass Fibers that is PA6 GF45, medium viscosity and dimensional stability, the PA GF45has excellent rigidity and hi... | |

| PA66 GF15 Heat Stabilized (A2006C, A2016C) for Engineering Plastics | PA66 GF 15Heat Stabilized (A2006C, A2016C) for Engineering Plastics PA 66 GF 15is a 15% glass fiber reinforced, heat-resistance, polyamide 66 resi... | |

| Color Masterbatch | As one ofmasterbatch suppliers, Anmei serves customers with tailored-making solutions from standard colors to customized colors and functions. Ther... | |

| Nylon66 pa66 | Nylon 66 is polyamide 66. The main purpose of Nylon 66 plastic modification is to improve the properties of Nylon 66 material based on the original... |

Похожие товары

| Defoamer Powder | Продавец: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |