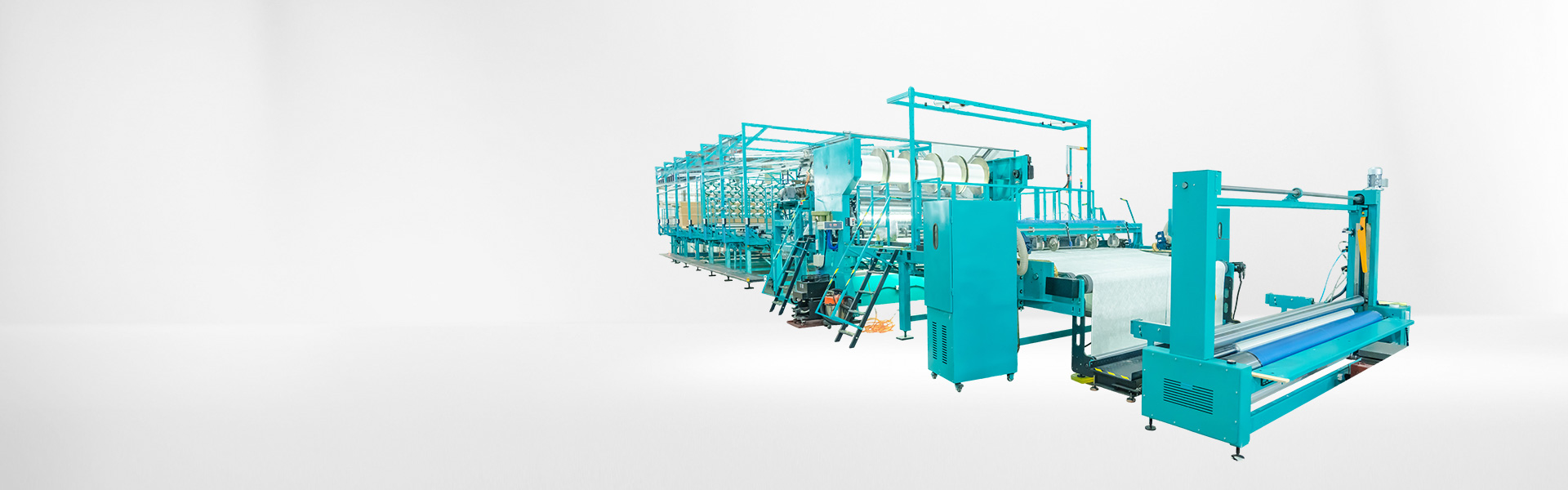

MULTI-AXIAL WARP KNITTING MACHINE

RSM3/3 series glass fibre and carbon fibre multi axial warp knitting machinedeveloped by Changzhou Run Feng Yuan Textile Machinery Manufacturing Co., Ltd. can bind warp knitting coils to warp, weft and oblique lining yarns through binding yarns to form multi-layer composite fabrics. The angle of oblique lining yarn is adjustable between 30°-60°. The number of layers of multi-axial warp knitted fabric can be adjusted according to needs, and the lined yarn can be all kinds of ordinary raw materials or high strength and high modulus yarns. According to the mechanical properties of the yarn, the multi-axial warp knitted fabric lined in layers has tensile and shear resistance in all directions, lightweight, flat surface, difficult corrosion and easy coating. It is widely used as the base cloth of textile composites in various industries such as filtration and reinforcement, as well as in various high-tech materials such as aviation and aerospace.

RUN FENG YUAN MULTI-AXIAL WARP KNITTING MACHINE FOR SALE

Glass Fiber Warp Knitting Machine

Carbon Fiber Warp Knitting Machine

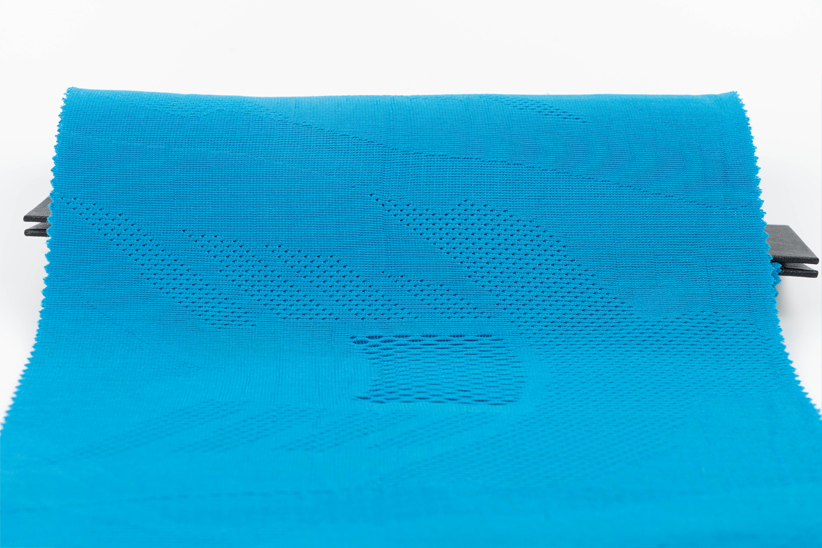

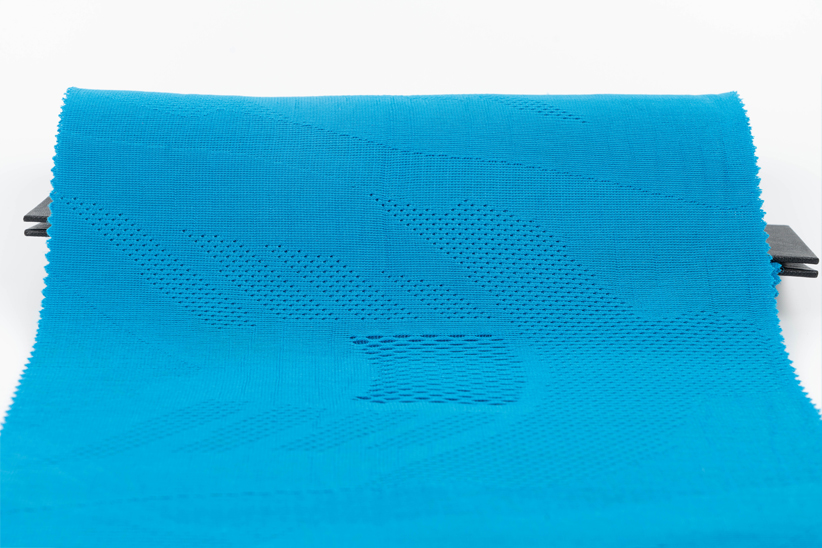

WHAT IS MULTIAXIAL WARP KNITTED FABRIC?

The multi-layer composite fabric produced on the "multi axial Raschel warp knitting machine" is formed by the warp knitting coil binding the warp, weft and oblique three-way full width weft lining yarn together. The angle of oblique lining yarn is adjustable between 30 °- 60°.

APPLICATION OF MULTIAXIAL WARP KNITTED FABRIC IN WIND POWER FIELD

Multi axial warp knitted reinforced materials are increasingly used to manufacture wind turbine blades because of their unique properties. Generally, when designing the blade skin, the fabric structure (uniaxial, biaxial and multiaxial) can be selected according to the different forces. Multi axial fabric is mainly used at the root of the blade. The reasonable laying of 40 layers of fabric is used to bear the shear force generated by torque.

As a professional textile machine factory, we provide geogrid warp knitting machine, chopping stitch bonding machine, jacquard machine, etc.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| MULTI-AXIAL WARP KNITTING MACHINE | RSM3/3 series glass fibre and carbon fibre multi axial warp knitting machinedeveloped by Changzhou Run Feng Yuan Textile Machinery Manufacturing Co... | |

| JACQUARD DOUBLE NEEDLE BAR WARP KNITTING MACHINE | Run Feng Yuan Jacquard double needle bed warp knitting machineare machines with the Jacquard pattern which are available for shoe mattresses and be... | |

| NON-WOVEN INTERLINING STITCH BONDING MACHINE | Non woven textile machinerystrengthens the fastness and toughness of the fabrics. After processing, the fibre mesh structure will become compact an... | |

| CURTAIN LACE MACHINE | Run Feng Yuan Curtain Lace Machineare raschel machines with fall plates that produce curtains, outwear and tablecloths with different jacquard patt... | |

| JACQUARD DOUBLE NEEDLE BAR WARP KNITTING MACHINE | Run Feng Yuan Jacquard affordable double needle bar raschel knitting machine are machines with the Jacquard pattern which are available for shoe ma... |

Похожие товары

| MaAnt M061 олово волочения иглы FPC разъем позолоченный припой бар | Продавец: Shenzhen Wikshu Technology Co. | Набор паяльных штифтов MaAnt M061 с золотым покрытием и легкой ручкой из углеродного волокна для ... | |

| High Hardness Linear Rail Flat Bed CNC Lathe | Продавец: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | It can cut all kinds of turning surfaces by bicycle, such as conical surfaces, special surfaces, ... | |

| Automation Suction Cups | Продавец: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | The ALUMINUM SUCTION CUP 6106 D is a versatile and reliable tool designed to handle various lif... | |

| Machinery | Продавец: O&K GROUP LIMITED | Okwishing supplies all kinds of Machinery. Okwishing () is a cross-border e-commerce platform de... | |

| Mini Excavator Carrier Roller for Kobelco SK045/SK045SR/SK50SR/SK70SR | Продавец: Xiamen Globe Truth (GT) Industries Co., Ltd | The carrier roller use 50Mn steel, after free forging into work-piece by a 560KG air hammer, comp... |