What Are the Advantages of an Oil Well Bit?

What Are the Advantages of an Oil Well Bit?

The oil wellbitis one of the widely used drilling bits, which has the characteristics of adapting to a wide range of formations and high drilling speed of machinery and equipment.

The oil well drill bit is composed of more than 20 parts such as cutting structure, bearing structure, locking element, oil storage seal installation and nozzle installation. The current motor is repeatedly used by the motor in the wellbore, forming the front part of the motor with greater rigidity, smaller relative discharge area, and higher relative return velocity. The upper annulus is taken to form a vortex that affects the cuttings at the front. The formation of accumulation affects the drilling speed, and further formation of the repeated fragmentation of those cuttings by the PDC drill bit, which is easy to form a mud pack of the bit remover.

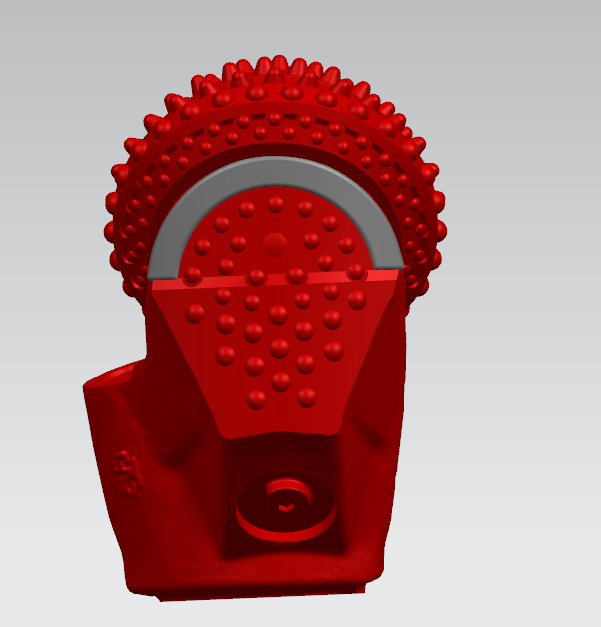

(1) The steel ball is used to lock the roller, which can be suitable for relatively high speed.

(2) The O-ring seal adopts a wear-resistant, highly saturated nitrile rubber, which increases the cross-section of the seal ring, and adds a small sealing boss at the outer end of the seal area to improve the sealing performance.

(3) The oil well drill bit uses high-strength and high-toughness alloy teeth, which improves the ability of the teeth to resist impact and reduces the probability of tooth breakage. Soft formations are inlaid with spoon-shaped teeth.

(4) The bearing of the palm of the oil well bit is covered with a layer of hard alloy, and there is also a silver-plated layer on the roller shaft to improve the anti-bite and load-bearing capacity.

(5) The oil well drill bit uses a grease that can withstand a temperature of 250°C and has low wear, which improves the ability of the drill bit.

(6) The optimized number of teeth of the oil well bit and the equipment such as exposed teeth and alloy teeth can realize the bit cutting and speed at a larger height.

If you want to know more details of drill bit manufacture, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| PDC Bit | PDC Bit PDC bit is Polycrystalline Diamond Compact bit ,it also named Diamond bit. pdc bit classification According to the Material Classification... | |

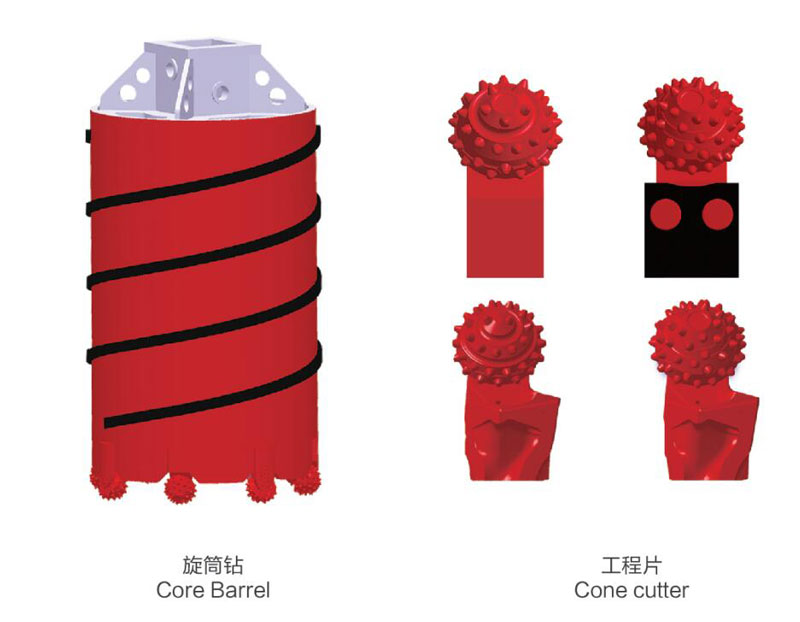

| Core barrel with high performance rock roller bit for Pile Foundation | Overview of Core Barrel Roller Bit Cangzhou Great Drill Bits Co.,Ltd.is one of the drill bit manufacturers in China. Its roller bit core barreluses... | |

| Tungsten Carbide Single Rock Tricone Roller Bit Welding Cone Bit Cutter | Overview of 120 ° UShaped Drill Bit Great Drill Bitshas customized manufacture several types of roller bit. The traditional single roller bi... | |

| Roller Bit | GREAT has customized manufacture several types of roller bit. Our roller cone drill bit includes the 90 ° U-shaped Roller Bit series and the 12... | |

| Bi-center Bit | Bi-center bit for Mining Machinery and abrasive formation Overview of Bi-center Bit This type of Bi-center bit mainly used for medium to medium-har... |

Похожие товары

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Продавец: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |