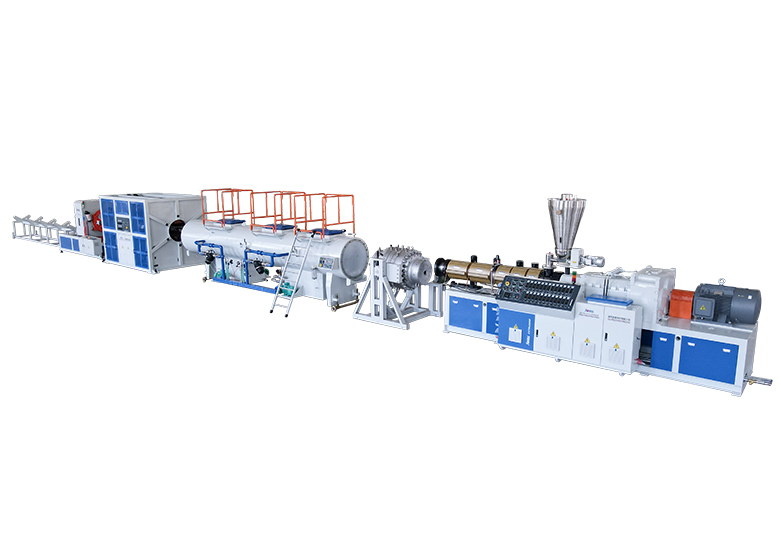

Pipe Extrusion Line

As a pipe extruder manufacturer, Jwell offers different types pipe extrusion machine to meet production for various pipes with different applications, such as PVC pipe, HDPE pipe, PP-R pipe, RTP pipe, PLA degradable straw, Electrical conduit pipe, Corrugated pipe, Steel reinforced spiral pipe, Silicon core pipe, Medical tube, Hollow pipe, Threading pipe, Communication pipe, Multilayer pipe and Technical pipe, etc.

All series pipe extrusion lines adopt high-efficient extruder to ensure higher output, better plasticizing, lower energy consumption and stable production. Based on Jwell special screw structure and advanced extrusion technology, our high quality pipe extrusion machines are suitable for processing many different polymers to meet customers requirements.

We choose Intelligent SIEMENS PLC control system, ABB inverter, high-end transmission system and precision electrical components, which can highly improve the equipment performance and make the operation process very easy.

Pipe Extrusion Line Lists

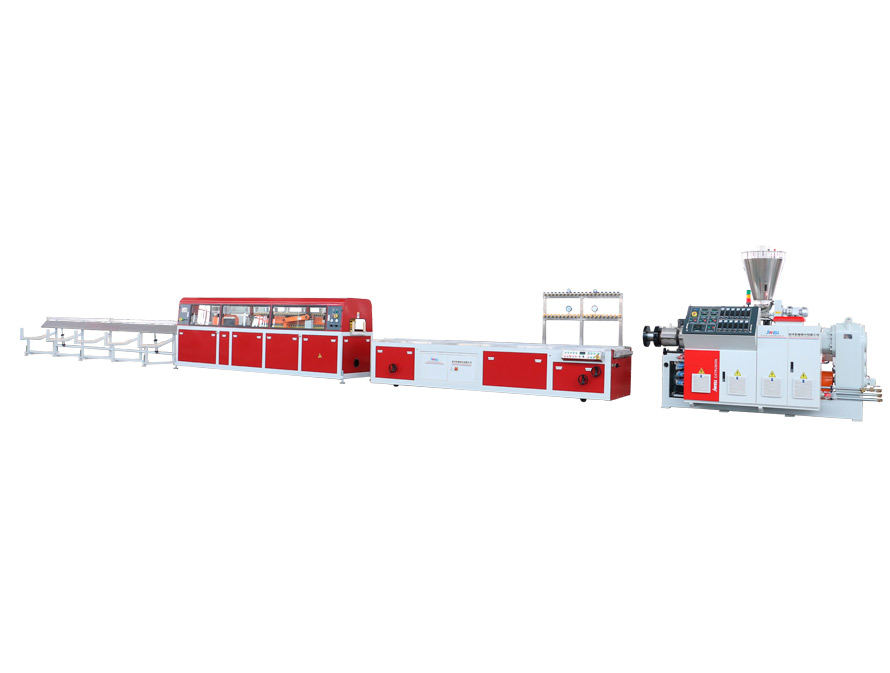

PVC Pipe Extrusion Line

UPVC CPVC Water Supply Drainage Pipe Extrusion Line

PVC Electrical Conduit Pipe Extrusion Line

PVC Silent Water Drainage Pipe Extrusion Line

PVC Double-cavity/Four-cavity Pipe Extrusion Line

Three-Layer PVC Pipe Co-extrusion Line

PVC Communication Threading Pipe Extrusion Line

PVC Medical Tube Extrusion Line

PVC Hollow Winding Pipe Extrusion Line

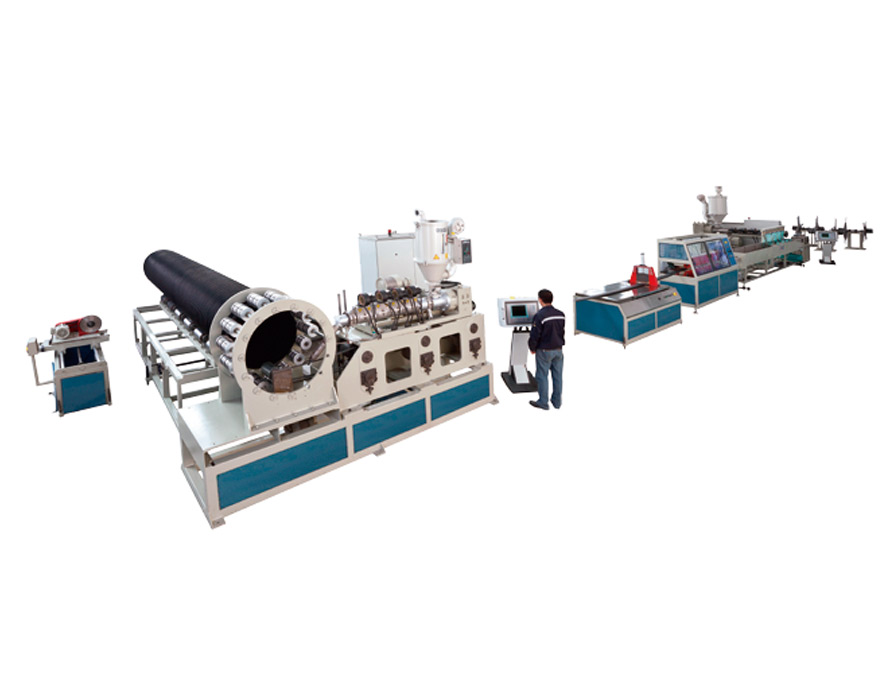

HDPE Pipe Extrusion Line

Large Diameter 800-2000mm HDPE Water Gas Supply Pipe Extrusion Line

High Quality 63-630mm PE Pipe Extrusion Line

PE Steel Reinforced Spiral Pipe Extrusion Line

PE Insulation Pipe Extrusion Line

High Speed and Energy Saving HDPE Pipe Extrusion Line

Multi-layer HDPE Solid Wall Pipe Co-extrusion Line

MPP PE Electrical Conduit Pipe Extrusion Line

PE, PP, ABS Film Roll Core Tube Extrusion Line

Corrugated Pipe Extrusion Line

Horizontal Double Wall Corrugated Pipe Extrusion Line

Vertical Double Wall Corrugated Pipe Extrusion Line

Special Plastic Pipe Extrusion Line

PP-R, PE-RT, PE-X Cool & Hot Water Small Pipe Extrusion Line

High Pressure RTP Twisted Composite Pipe Extrusion Line

Silicon Core Pipe Extrusion Line

3D Printer Filament Extrusion Line

PLA Biodegradable Straw Extrusion Line

Fiber Glass PPR Pipe Co-extrusion Line

PP Pipe Extrusion Line

Common VS Jwell Pipe Extrusion Machine

Jwell Pipe Extrusion Machine

Jwell China Plastic Pipe Extrusion Machine

We are a 25-year manufacturing vendor with vertical set-up, which means we have a great control of supply chain and we are cost-effective. There're over 3000 employees working at Jwell so that we can offer reliable, professional and sustainable service for customers at any time. As a plastic extrusion machine supplier, Jwell has specialized in plastic extrusion technology for over 25 years with rich experience, driving plastic extrusion industry keep forward. Our extrusion line has the advantages of good melt homogeneity, better plasticization, higher output and long service time.

Common China Plastic Pipe Extruder

Most manufacturers often change component suppliers or take much time to order spare parts. They adopt outdated technical specification for extrusion machine without reducing energy consumption or improve production capacity. Many our customers who used these old machines said although the price of these pipe machines are very low, they cannot be used for a long time. Also, some manufacturers can't offer reliable service, because they don't have enough resource to support it.

Factors Affecting Extrusion Machine Production

Screw structure

Different screw structures directly affect the plasticization of plastic raw materials and the quality and output of final products.

Transmission system

Provide the screw with appropriate speed range, stable speed and uniform torque, and be able to withstand the huge screw axial force generated in the production process.

Electronic control system

Great electronic control system can ensure smooth production and affects performance of heating, cooling and pressure system.

Heating and Cooling system

Accurate and uniform heating and cooling system play an important role in screw extrusion and calibration, then affects thickness and surface of final products.

What is Pipe Extrusion Process?

There are six steps during pipe extrusion process. Firstly, mix material, then extrusion part, pipe calibration, cooling, haul off, cutting. The following are the causes and solutions of some problems during pipe production process.

Corrugation on pipe surface

Vibration

Pit on surface

Nonuniform wall thickness

Corrugation on pipe surface

Insufficient cooling: It is necessary to increase the water inlet of the sizing sleeve or increase the spacing between the die and the sizing sleeve.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

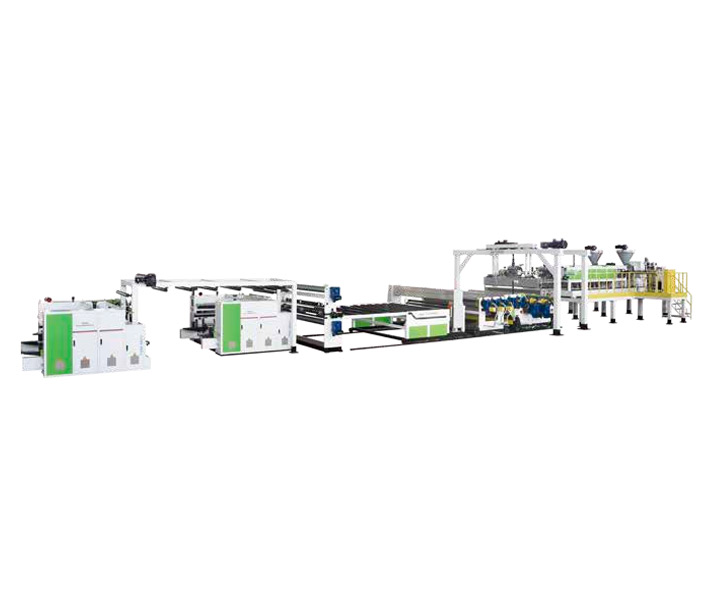

| PVC WPC Panel Board Extrusion Line | Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 years, also have ranked No.1 in the extrusion indu... | |

| PVC Wall Panel Extrusion Line | Jwell extrusion machineryspecializes in complete solutions for various PVC wall panel extrusion line, from plant planing to final profiles. This hi... | |

| High Pressure RTP Twisted Composite Pipe Extrusion Line | As a leading pipe extrusion machine line supplier, Jwell provides quality composite pipe extrusion production lines for RTP. RTP (Reinforced Thermo... | |

| Film Extrusion Line | We have own experimental institution and professional company to research and develop high-performance plastic film extrusion machines. The main fi... | |

| CPP, CPE Cast Film Extrusion Line | We are professional at manufacturing complete cast film extrusionline with over 25 years' rich experience, highly improving the production efficien... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |