WHAT IS SHOCK TEST?

Shock environment is a transient physical accelerating, such as impact, free-fall, kick, earthquake, or explosion.

A shock pulse can be characterized by its peak acceleration, the duration, and the shape of the shock pulse (half sine, post-peak sawtooth, trapezoid, etc.).

There are various shock phenomena in the production, transportation and operation in various industries such as aviation, aerospace, navigation, weapons, and electronics, which have a great negative impact on the quality and reliability of the products. In order to solve this problem, a shock test was produced and developed on this basis. After more than one hundred years of development, the shock test technology has become quite mature, and it also plays an irreplaceable role in national defense and civil industries.

CME offers high-qualityshock test equipmentfor sale at good prices. Welcome to contact us!

HOW TO PERFORM SHOCK TESTING

There are three ways to do shock testing:01Explosion method of pyrotechnic device

The advantage of the pyrotechnic product explosion method simulation test technology is that it can produce the most accurate simulation results, and can produce the high acceleration and high frequency range unique to the near-zone explosion shock environment. The main disadvantages are high test cost, poor safety and large dispersion of loading levels.

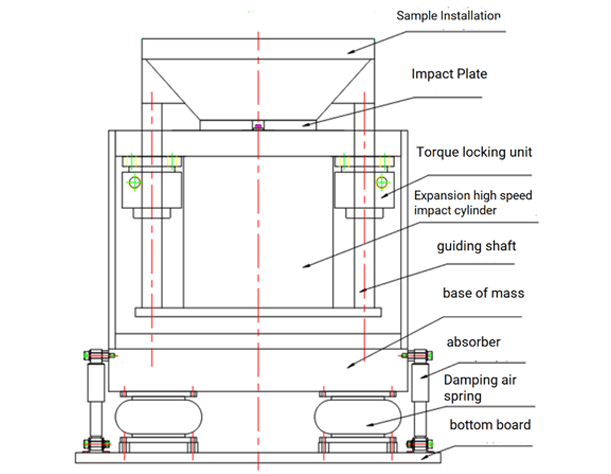

02Mechanical shock method

The main advantages of shock simulation equipment are relatively low operating costs, good repeatability, and high predictability of loading levels, but they have some limitations in their ability to generate shock spectra.

03Vibration table simulation method

With the development of vibration table control technology, shock testing that simulate low-amplitude complex shock environments have been realized on the vibrating table.

WHY IS SHOCK TESTING SO IMPORTANT?

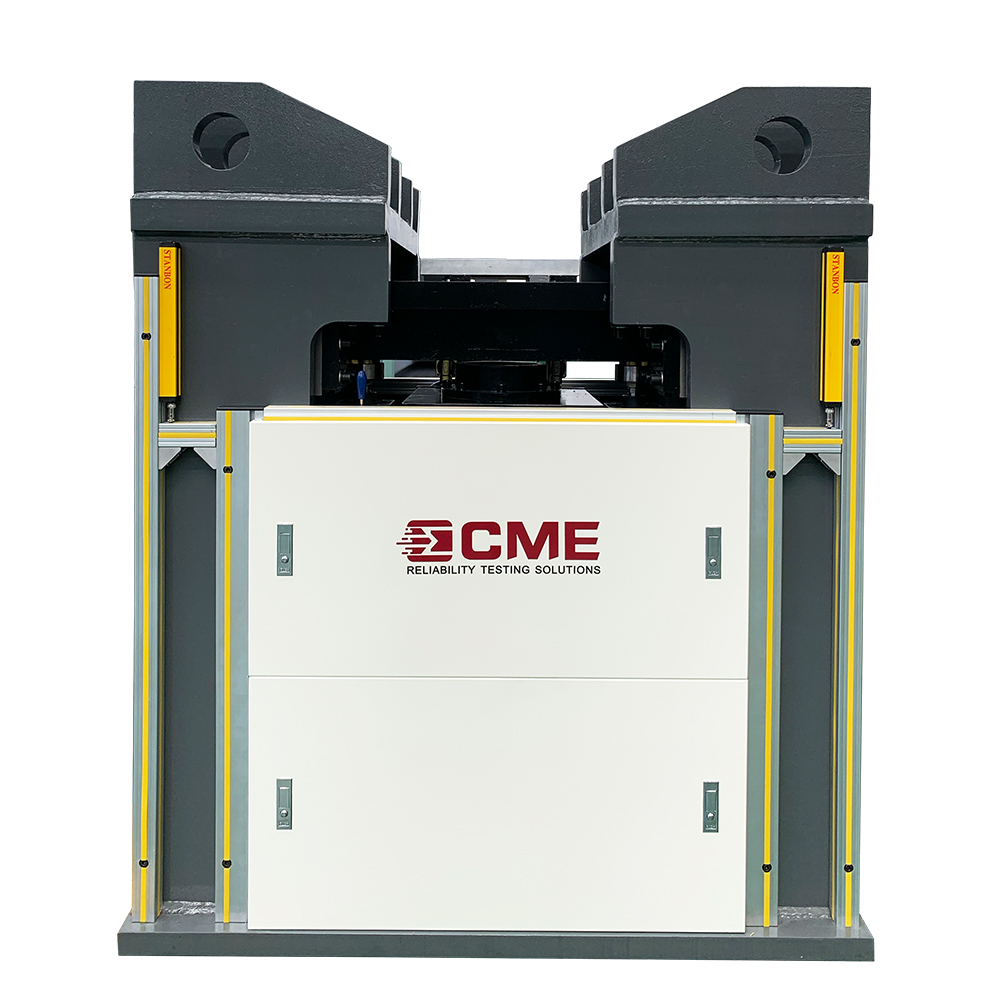

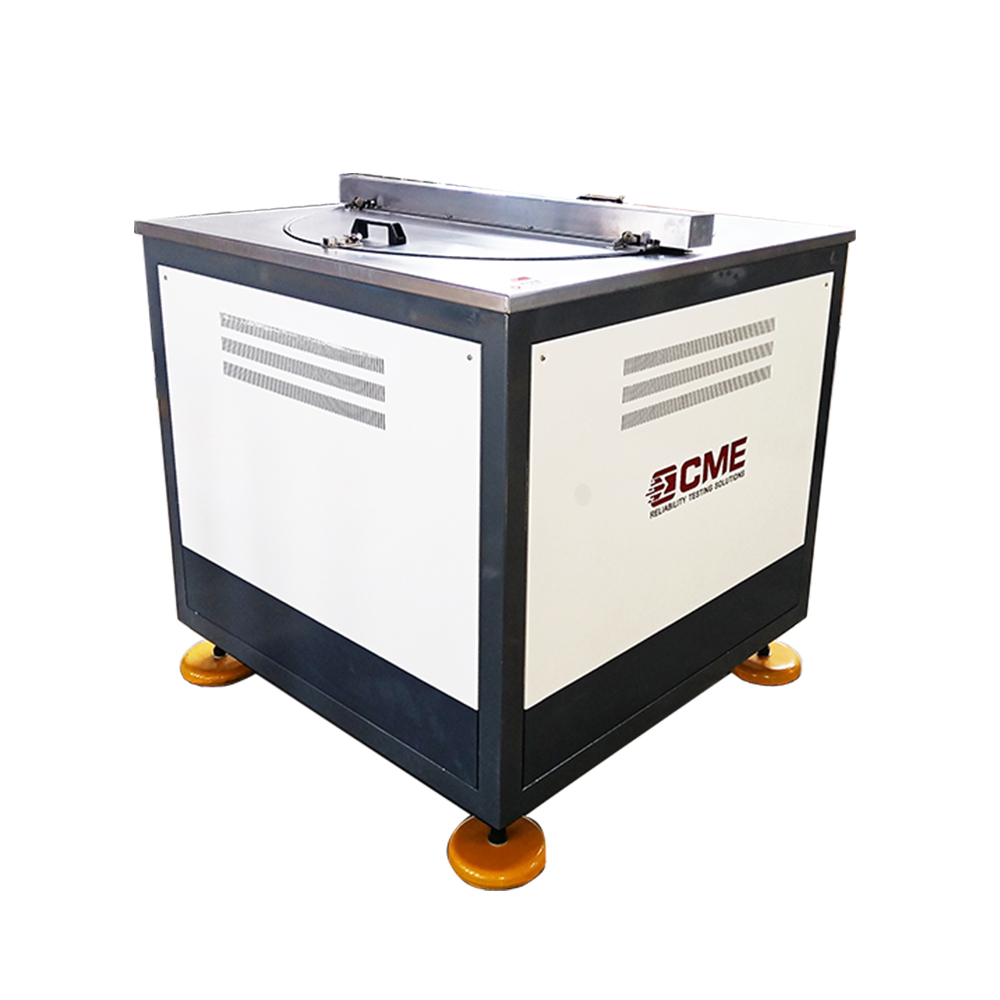

Shock testing machineis used to measure and determine the impact resistance of products or packaging, and to evaluate the reliability and structural integrity of products in a shock environment. The impact testing equipmentsystem can perform conventional half-sine wave, post-peak sawtooth wave, or square wave shock test to realize the shock energy that the product is subjected to in the actual environment, thereby improving the product or packaging structure.

CME shock/bump test system meet the requirements of MIL-STD-202, MIL-STD-750, MIL-STD-810, MIL-STD-883, IEC68-2-27 and other shock testingmachine standards.

For more information about mechanical test equipmentand drop test machine, please feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| KRD200 CENTER OF GRAVITY MEASUREMENT SYSTEM | The center of gravity test(CG) (or center of mass) of an object is the average location of the weight (or mass). It's a crucial mass property in th... | |

| KRD14 PNEUMATIC VERTICAL SHOCK RESPONSE SPECTRUM TEST SYSTEM | KRD14 series shock response spectrum test system is full pneumatic driven vertical lifting SRS test equipment with special design, easy operation, ... | |

| KRD16 High Impact Shock Test System | KRD16series shock test system is a standard testing equipmentstipulated by the high impact shock test method and meets MIL-S-901D standard which co... | |

| KRD32 NON-STANDARD CONSTANT ACCELERATION TESTER | KRD32 series non-standard constant centrifuge acceleration testingmachineis a box-type test machine for electronic components, small components, an... | |

| KRD13 High Energy Shock Test System | KRD13 series pneumatic high-energy shock test system is an automatic pneumatic lifting vertical pressure mechanical shock and vibration testingequi... |

Похожие товары

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Продавец: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |