Excavator Cylinder Pins Induction Hardening

Excavator Cylinder Pins Induction Hardening

Product Description

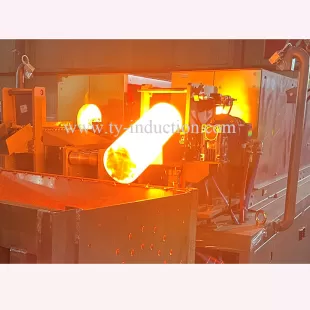

This Complete Induction Hardening System for Excavator Cylinder Pinsis a specialized equipment designed and produced by TY Induction for our customers in manufacturing and serving heavy machinery in construction industry. These pins play a crucial role in the performance and longevity of excavators. Induction Heat Treatment increases the strength and durability of excavator bucket pins.

This Complete Induction Hardening System for Excavator Bucket Pins includes eight (8) items: an IGBT Induction Power Converter, an output transformer, an induction coil, a quenching coil, a CNC quenching system, a closed-loop cooling system for both induction power converter and Quenching media, a CNC control system and an UPS power.

The Induction Power Supply generates high-frequency alternating current, which is supplied to the output transformer further to induction coil. The coil is designed to produce an intense electromagnetic field, which is responsible for heating the surface of the excavator bucket pins inside coil.

A bucket pin is precisely positioned inside the induction coil during the Induction Heat Treating process. Once the Induction Hardening Equipment starts up, the induction coil starts moving progressively and electromagnetic field generated by the coil rapidly heats the surface layer of the pin.

After reaching the desired temperature, the quenching system starts to work. The pin is quickly cooled with quenching media sprayed from the quenching coil, which usually contains a specialized quenching medium such as oil, water or polymer. Rapid cooling of the heated surface helps transform the metal structure and form a hardened layer. The quenching process significantly improves the hardness, wear resistance and overall strength of the excavator bucket pin. CNC Control systems in Induction Heat Treatment systemsprecisely regulate the heating and cooling processes. Operators can set specific parameters such as heating time, temperature and traveling speed of induction coil, flow and pressure of quenching medium for consistent and optimized hardening pattern.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| induction heating machine for forging | Induction Heating Machine For ForgingWhat is induction forging? Induction forginguses induction heating of metal parts before they are formed or "... | |

| Induction Brazing Heater | Induction brazing equipment is a type of machinery used for the process of brazing. Brazing is a method of joining two or more metal components by ... | |

| Induction Annealing Machine | Induction Annealing Machine Product Description Induction annealing is a process used to heat metal components using an electromagnetic field. An... | |

| Induction Hardening Equipment | Induction Hardening EquipmentWhat is induction hardening? Induction hardeninguses induction heating and rapid cooling (quenching) to increase the ... | |

| Induction Chain Hardening and Tempering Equipment | Induction Chain Hardening and Tempering Equipment Product Description Induction heating is a fast, precise, environmentally friendly, energy-savi... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |