Excavator Cylinder Pins Induction Hardening

Excavator Cylinder Pins Induction Hardening

Product Description

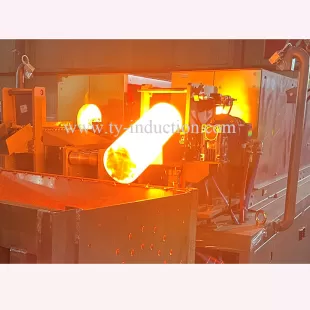

This Complete Induction Hardening System for Excavator Cylinder Pinsis a specialized equipment designed and produced by TY Induction for our customers in manufacturing and serving heavy machinery in construction industry. These pins play a crucial role in the performance and longevity of excavators. Induction Heat Treatment increases the strength and durability of excavator bucket pins.

This Complete Induction Hardening System for Excavator Bucket Pins includes eight (8) items: an IGBT Induction Power Converter, an output transformer, an induction coil, a quenching coil, a CNC quenching system, a closed-loop cooling system for both induction power converter and Quenching media, a CNC control system and an UPS power.

The Induction Power Supply generates high-frequency alternating current, which is supplied to the output transformer further to induction coil. The coil is designed to produce an intense electromagnetic field, which is responsible for heating the surface of the excavator bucket pins inside coil.

A bucket pin is precisely positioned inside the induction coil during the Induction Heat Treating process. Once the Induction Hardening Equipment starts up, the induction coil starts moving progressively and electromagnetic field generated by the coil rapidly heats the surface layer of the pin.

After reaching the desired temperature, the quenching system starts to work. The pin is quickly cooled with quenching media sprayed from the quenching coil, which usually contains a specialized quenching medium such as oil, water or polymer. Rapid cooling of the heated surface helps transform the metal structure and form a hardened layer. The quenching process significantly improves the hardness, wear resistance and overall strength of the excavator bucket pin. CNC Control systems in Induction Heat Treatment systemsprecisely regulate the heating and cooling processes. Operators can set specific parameters such as heating time, temperature and traveling speed of induction coil, flow and pressure of quenching medium for consistent and optimized hardening pattern.

Send product request

Other supplier products

| Induction Hardening Equipment | Induction Hardening EquipmentWhat is induction hardening? Induction hardeninguses induction heating and rapid cooling (quenching) to increase the ... | |

| Induction Pipe and Tube Bending Equipment | An induction pipe bending machineis a specialized machine that uses induction heating to heat a section of pipe to a specific temperature before be... | |

| induction brazing equipment | Induction Brazing Equipment What is induction brazing? Induction brazingis a process that uses induction heating to join two or more metals. Indu... | |

| Sucker Rod Induction Forging | Metal forging is to use the malleability of metal and its ability to produce malleable deformation to form a blank into a part or blank with a cert... | |

| induction heating machine for forging | Induction Heating Machine For ForgingWhat is induction forging? Induction forginguses induction heating of metal parts before they are formed or "... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |