Palm Oil Wastewater

Palm Oil Wastewater

Palm oil is not only the highest yielding cheap vegetable oil on the earth but also a safe raw material for edible oils and daily chemicals, and a raw material for biofuel.

As a raw material for edible vegetable oils, chemical raw materials and biofuel, palm oil has attracted worldwide attention in the process of ecological protection and industrial pollution. As a result, palm oil wastewater treatmentalso receives much attention.

Palm oil mill effluent (POME)is a yellow liquid with a unique unpleasant smell and comes from oil extraction, cleaning and washing process in the POME factory, which is featured with very high COD and BOD.

Due to its acidic nature (pH 3.4–5.2), high salt and suspended solids, oil and grease, the untreated discharge of POME can result in considerable environmental consequences.

Each ton of palm oil produced emits about 20 tons of high-concentration organic wastewater. When the high-concentration organic wastewater per ton is treated according to the current sewage pond treatment method, it is equivalent to emitting more than 210 million tons of carbon dioxide gas into the atmosphere every year. It's important to solve the problems in palm oil mill effluent treatment.

To achieve environmental requirements and economic challenges, the POME factories are trying to get efficient and return on the investment process.

JIUWU HITECHhas made a lot of studies and many rich experiences for POME treatment since 2012.

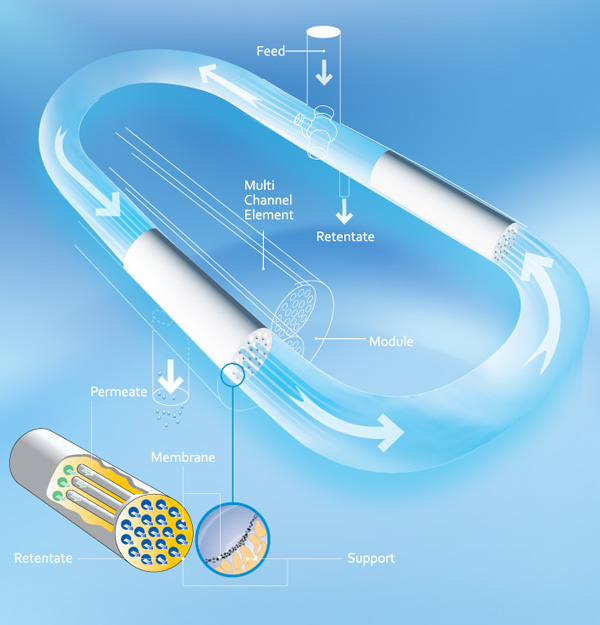

JIUWU HI-TECH offers the solution for POME treatment with an integrated ceramic membrane technology which is a green, friendly environment, economic efficiency and has the following technical benefits:

No discharge of wastewater

Low capital investment ;

Low operation cost;

Oil is concentrated and water is recycled

After integrated process filtration, concentrate including surplus sludge from anaerobic and centrifuge is used as fertilizer for cattle farm and purified water can be used for recycling or the bolier feed water due to salts and organic compounds are removed.

If you are looking for a reliable ceramic membrane factory, please choose us, and we will be your best partner.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Microfiltration Ceramic Membrane Element | The ceramic microfiltrationmembrane element ( MF membrane) is made from alumina and zirconia which is an asymmetric membrane structure with multi-c... | |

| Ceramic Membrane | Ceramic membranes (Porous Ceramic Membrane& tubular ceramic membrane) are available for microfiltration, ultrafiltration and nanofiltration as ... | |

| SS Membrane Module | The stainless steel membranemodule is designed by different applications. Stainless steel could be used as the material of module/housing, that is,... | |

| Microfiltration Ceramic Membrane Element | The ceramic microfiltration membraneelement ( MF membrane) is made from alumina and zirconia which is an asymmetric membrane structure with multi-c... | |

| Nanofiltration Ceramic Membrane Element | Ceramic Nanofiltration membrane is relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-produ... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |