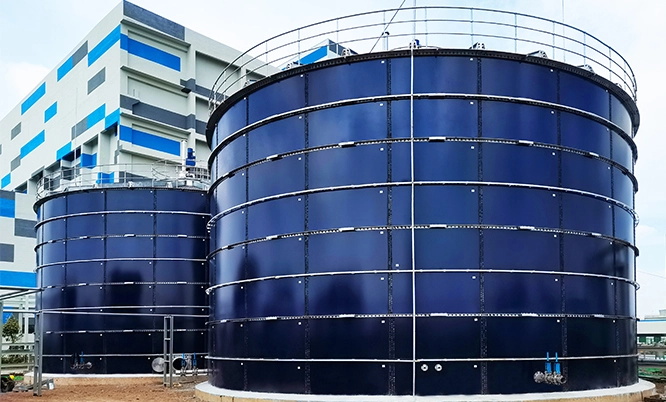

Epoxy Coated Steel Tanks

Epoxy coated steel tanksare a type of storage tank that features an Internal coating - Thermoset resin fusion bonded epoxy and an External Coating - Ultra-durable polyester. Epoxy coating through Bonded Epoxy and curing agent 200 degrees of melting and curing, creating a strong and flexible thermosetting polymer coating. This coating helps prevent corrosion and can protect stored fluids from contamination, making them ideal for storing a variety of fluids such as drinking water, process, and wastewater storage.

FBE tanks are tested to rigorous standards and meet, exceed, or provide comparable performance to a wide range of internationally recognized coating requirements. Epoxy tankshave become a popular choice across various industries due to their durability, cost-effectiveness, and low maintenance requirements.

FBE-1500V Epoxy Coated Steel Tanks

FBE-1500V coatings are thicker coatings that pass the 1500V holiday test with a minimum dry film thickness of 12 mils/300 microns. It offers better corrosion protection and is often used in more aggressive environments, such as wastewater and sewage treatment tanks. Both types of epoxy coated steel tanks have excellent corrosion resistance, but the FBE-1500V offers better performance for tanks in harsh environments.

FBE-1100V Epoxy Coated Steel Tanks

Epoxy-coated steel superior water tanksare available in two models: FBE-1500V and FBE-1100V. FBE-1500V and FBE-1100V refer to the thickness of epoxy coatings and the level of corrosion resistance they provide. FBE-1100V coating is the standard coating for most steel storage tanks, passed the 1100V holiday test, with a minimum dry film thickness of 12 mils/200 microns, and has good corrosion resistance. This type of coating is commonly used in water storage tanks and other industrial applications.

USES OF EPOXY COATED STEEL TANKS

Epoxy coated steel tanks are often used for less demanding applications where lower cost and moderate corrosion resistance are acceptable, such as in the storage of potable water, industrial liquids, or materials that produce moderate corrosion.

EPOXY COATED STEEL TANKS MANUFACTURING PROCESS

The process of coating steel with epoxy typically involves three main steps. The first step is surface preparation, which involves cleaning the steel to remove any dirt, rust, or other contaminants that may prevent the epoxy from bonding properly. This can be done using various methods, such as sandblasting or chemical cleaning.

The second step is the application of the epoxy coating, mainly through electrostatic spraying to complete. Depending on the application and the type of epoxy being used, multiple coats may be necessary to achieve the desired level of protection.

Finally, the coated steel is cured at a specific temperature and for a set amount of time. This allows the epoxy to fully harden and bond to the steel, creating a durable and long-lasting protective coating.

Epoxy-coated steel is commonly used in applications where corrosion resistance is required, such as in pipelines, tanks, and other industrial equipment. It can also be used in architectural applications.

As one of epoxy tank manufacturers, we can provide kinds of liquid storage tanks for sale, if you want to buy bulk storage tanks for liquids, please contact us.

If you want to know more types of bolted tanks, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Epoxy Coated Steel Tanks | Epoxy coated steel tanksare a type of storage tank that features an Internal coating - Thermoset resin fusion bonded epoxy and an External Coating ... | |

| Tank Roofs and Covers | oil tank roofand covers are critical components of storage tanks designed to protect the stored media from the elements while ensuring safe operati... | |

| YHR-Bolted Steel Tanks Manufacturer | YHR has been committed to creating bolted tanks for more than 20 years. It provides bolted tanks and services for municipal, agricultural, industri... | |

| TROUGH DECK ROOF | Trough Deck Roofis a type of roof that is made up of a series of steel panels that are joined together to form a trough shape. The panels are typic... | |

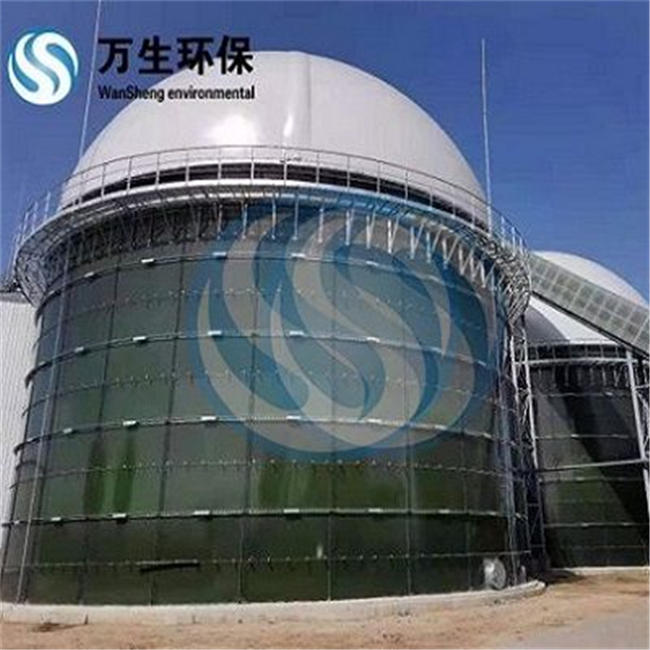

| Biogas Holder | A biogas gas holderis used for storing and regulating the pressure of biogas produced from organic waste. The stored biogas can then be used as a s... |

Похожие товары

| Glass Lined Steel Continuous Stirred Tank Reactors (CSTRs) for Industrial Biogas Plants | Продавец: Wansheng Environmental Protection Engineering Co., Ltd | GFS tanksare assembled on-site from specialized enamel steel plates, hoops, self-locking bolts, s... | |

| Cryogenic Liquid Pump | Продавец: 854092 | Cryogenic Liquid Pump This series of pump is based on the advanced technology in the world... | |

| Marine LNG Fuel Storage Tank | Продавец: 854092 | Marine LNG Fuel Storage Tank The company produces various types of Marine LNG fuel storage t... | |

| Vertical Cryogenic Liquid Storage Tank | Продавец: 854092 | Vertical Cryogenic Liquid Storage Tank Vertical Cryogenic Liquid Storage Tank Our 0.8MP... | |

| Anaerobic Digester Tank | Продавец: Hebei Wansheng Environmental Protection Engineering Co., Ltd | Product Description Anaerobic digester tanks are a valuable tool for the management of organic... |