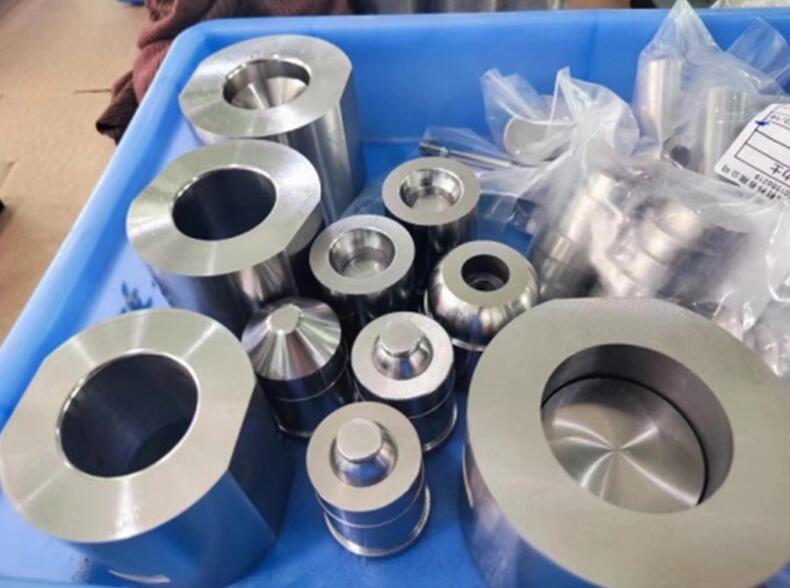

Carbide Mold Components

Carbide Components

We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die components from your CAD drawings. Our raw materials are imported from designated companies. Tungsten carbide has excellent hardness, wear resistance and corrosion and corrosion resistance. Ultra-hard tungsten carbide has a longer service life and can increase productivity through improved performance and reduced downtime.

Wear-resistant silicon carbide componentsare widely served by metal stamping production/manufacturing companies, custom metal fabrication, injection mold industry, metal mold/mold makers, tool and die makers and mold making industry.

What Has Cemented Carbide?

Cemented carbide is an alloy material made of hard compounds of refractory metals and bonded metals through a powder metallurgical process.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, better strength and toughness, heat resistance, corrosion resistance, etc. Especially its high hardness and wear resistance, even at a temperature of 500 ℃ also remains basically unchanged, at 1000 ℃ still has a high hardness.

Cemented carbide is widely used as tooling materials, such as turning tools, milling tools, planning tools, drills, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult to machine materials.

How Do You Make Hardware Mold Parts?

Precision etching is a process of creating patterns, shapes, and designs on a variety of materials, usually metals, using an etching process. As a part of precision quality machining, this process is often used in the manufacture of precision parts, such as integrated circuits, sensors, and other electronic components. In precision etching, the precision manufacturing companiescontrols the chemical reaction used to etch a desired pattern into the material, which is then filled with an etching fluid.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| EDM Spark | Electrical Discharge Machining ServicesSpark During the EDM process, an electric current crosses the gap between the electrode and the workpiece (... | |

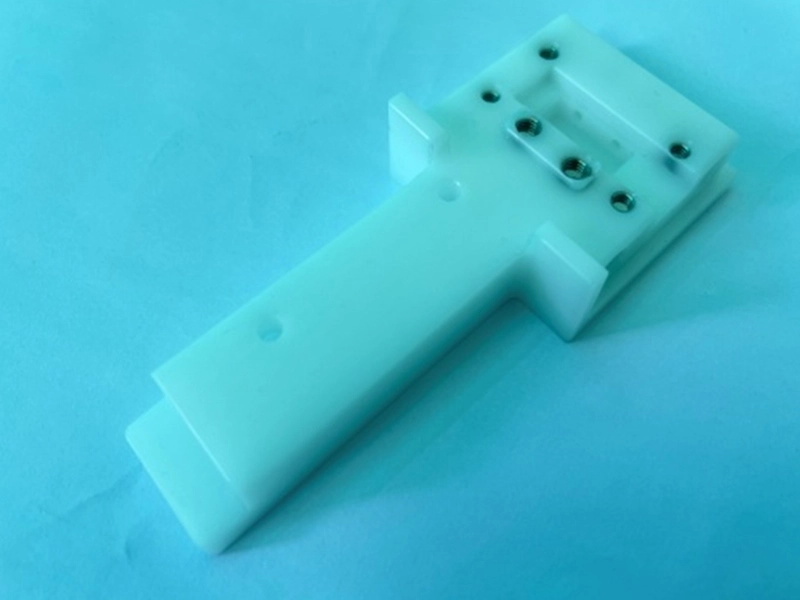

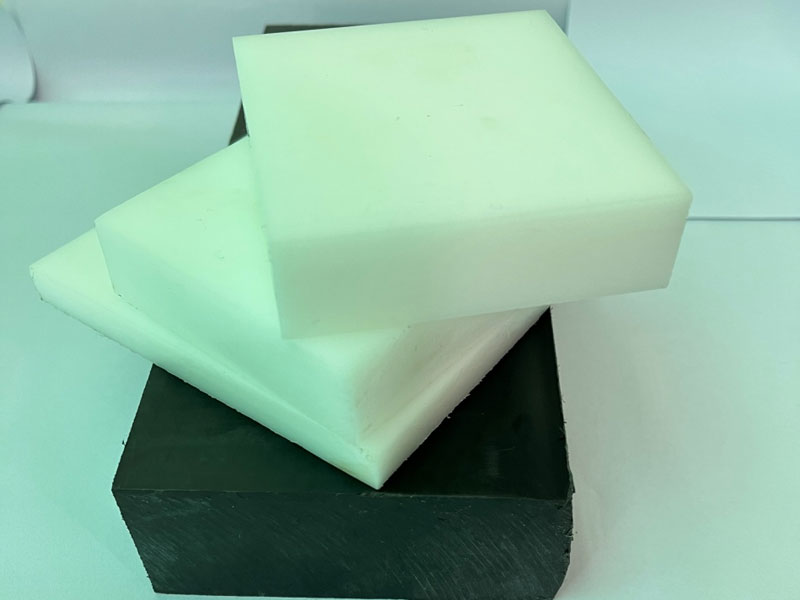

| Plastic CNC Machining Parts | Commonly used materials for plastic parts processing: ABS, POM, PC, PEEK, Bakelite, Nylon, etc. Specifically can be used for 3D printing, rapid pro... | |

| PEEK Non-standard Parts | PEEK Non-standard Parts PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mec... | |

| Aluminum Non-standard Parts | Aluminum Non-standard Parts Non-standard precision parts hardware processing is the raw materials (stainless steel, copper, aluminum, iron ......)... | |

| CNC Machining Material | Metal Material Machining Aluminum Alloys Aluminum alloy material is divided into: 6061 mainly contains magnesium and silicon elements, suitable... |

Похожие товары

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | Продавец: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | Продавец: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | Продавец: Wuhan Linkage Track Equipment Co., Ltd | ||

| Portable Rail Vertical Tamper | Продавец: Wuhan Linkage Track Equipment Co., Ltd | ||

| Подъемная труба как ключевой компонент машины для литья под низким давлением | Продавец: Карбидокремниевая техническая керамика | Являясь ключевым компонентом машины для литья под низким давлением, подъемная труба для жидкости ... |