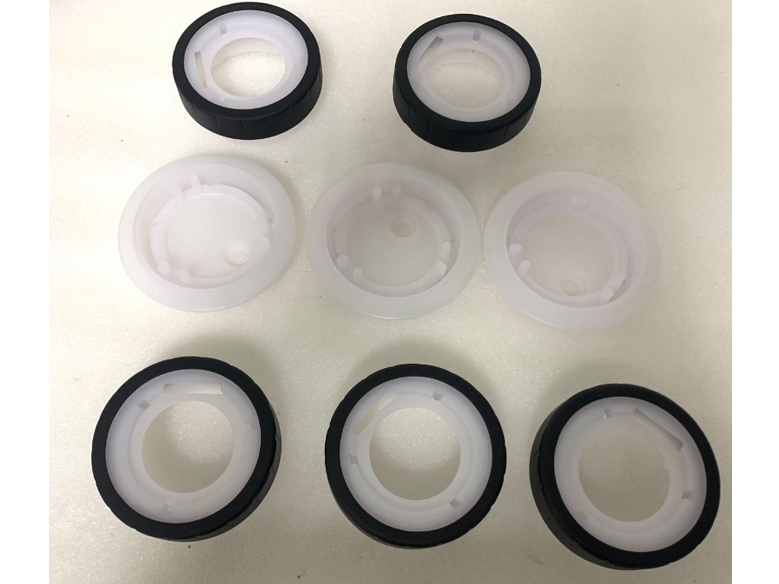

Silicone Prototyping

Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is widely used in the rapid prototype industry. The processing method of soft plastic rapid prototype is relatively single, and it can only be processed by vacuum Casting - that is use 3D printing or CNC processing to do a prototype, and then use vacuum casting /silicone mold to copy the prototype, generally a prototype can be copied 15~20 time.

Silicone PrototypingMaterial Properties

In the general plastic industry, PP, PE and other light gravity, material surface hardness is relatively low plastic known as soft glue. And PS, ABS, AS, hard PVC and other plastics can be called hard glue.

Heat resistance properties

Silicone products are silicon - oxygen (Si-O) key chain structure, C-C bond energy of 82.6 kilocalories/gram molecule, Si-O bond energy in silicone is 121 kilocalories/gram molecule, so the thermal stability of silicone products is high, high temperature (or radiation) molecular chemical bonds do not break, do not decompose. Silicone not only can withstand high temperature, but also low temperature, can be used in a wide temperature range. Both chemical and physical mechanical properties change very little with temperature.

Silicone cast prototypesMaterial Info

Brief introduction

Soft prototype silicone rubber partsis mainly processed by the way of silicone compound mold, its advantages are fast time, less cost, good operation, no deformation, no shrinkage, easy to dismantle the mold, the mold surface is smooth, the simulation effect is good, the probability of processing failure is small. 10-20 pieces of the same product can be copied by using a silica gel mold. Generally, a set of silica gel mold can only be done about 10-20 times and can not be used. Reuse can produce deformation and large size error. Soft rubber hand model because of these excellent properties, so its application is very wide, Soft rubber hand model production steps can be divided into three steps, before making silica gel mold, first of all to make a prototype, the prototype can use the more common ABS material, can be made by CNC processing or 3D printing; After the original is ready, began to make silica gel mold, after curing, the silica gel mold is cut, take out the prototype, at this time the silica gel mold is ready; The liquid material is injected into the silica gel mold and dried. The service life of the silica gel mold is about 10-20 times. In the raid prototype industry, as long as the soft adhesive material is PU 8400.

For more information about types of rapid prototypingand product design prototype, please feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

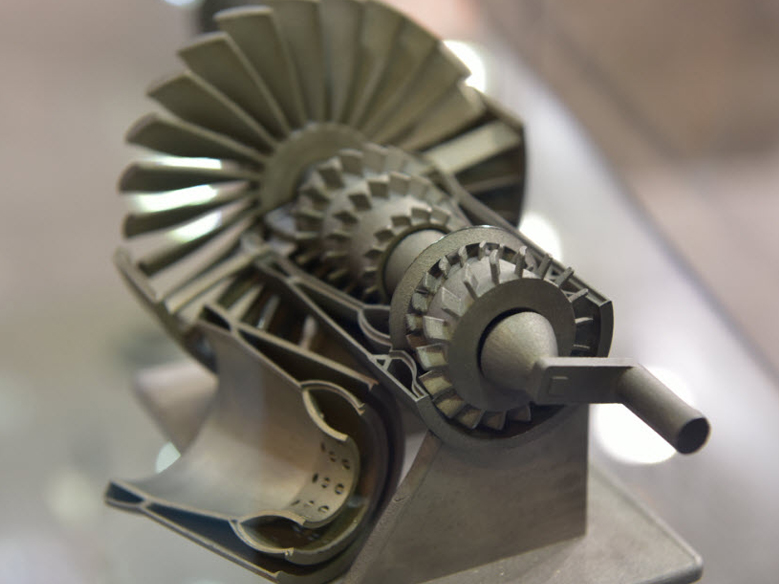

| Stainless Steel Printing | For parts with complex structure, stainless steel 3d printing servicecan realize integral printing forming, avoiding mass increase and potential qu... | |

| Silicone Prototyping | Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is wide... | |

| Silicone Prototyping | Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is wide... | |

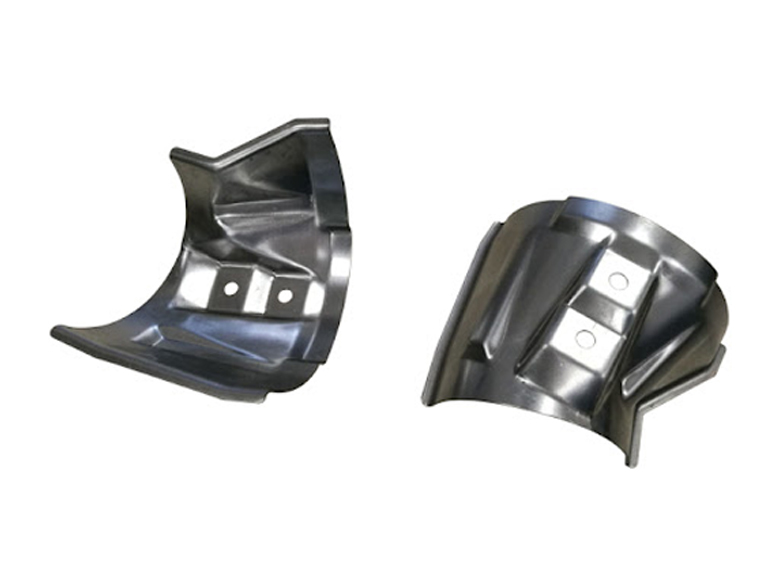

| Stamped Sheet Metal Parts | Stamped Sheet MetalParts Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil ... | |

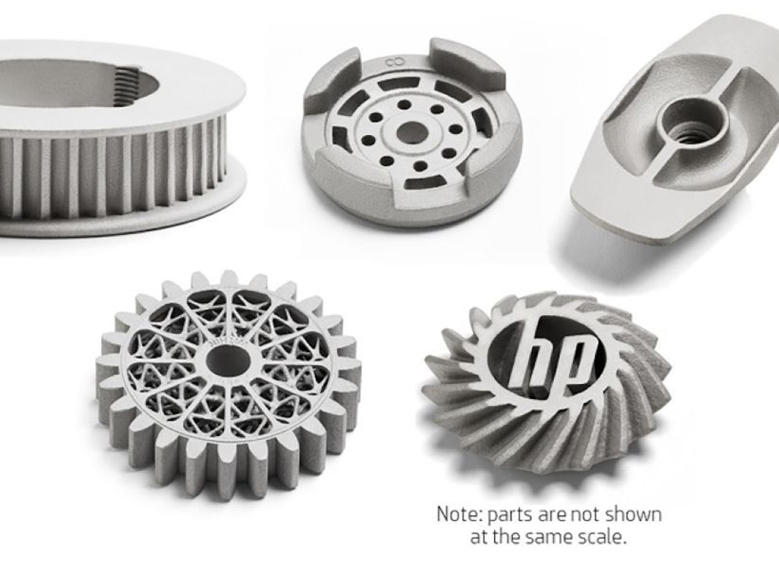

| SLS Nylon Printing | 3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3D printing with light weight a... |

Похожие товары

| Vacuum Casting Plastic | Продавец: Industry Proto-mold Limited | Vacuum casting process: free mold opening, low production cost, forming speed, high processing ac... | |

| Titanium 3D Printing Service | Продавец: Industry Proto-mold Limited | Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, ... | |

| Stamped Sheet Metal Parts | Продавец: Industry Proto-mold Limited | Stamped Sheet MetalParts Proto-mold purchased advanced large laser cutting machine 3 sets, Amada... | |

| Stainless Steel Printing | Продавец: Industry Proto-mold Limited | For parts with complex structure, stainless steel 3d printing servicecan realize integral printin... | |

| SLS Nylon Printing | Продавец: Industry Proto-mold Limited | 3D printed nylon parts can be used for product verification or directly used as functional produc... |