Nitrile rubber compound

Excellent oil resistance, high wear resistance, good heat resistance, strong adhesion. Its disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance, and slightly low elasticity. Nitrile rubber is mainly used to make oil-resistant rubber products.

| Category | Details |

|---|---|

| Composition | –Base Polymer: Nitrile Butadiene Rubber (NBR, acrylonitrile content 18–50%) |

| –Reinforcing Fillers: Carbon black (30–50 phr), clay (10–20 phr) | |

| –Plasticizers: Phthalate esters (5–15 phr) | |

| –Curing Agents: Sulfur/accelerators (1–4 phr) | |

| Physical Properties | –Hardness (Shore A): 40–90 (ASTM D2240) |

| –Tensile Strength: 10–25 MPa (ASTM D412) | |

| –Elongation at Break: 300–600% (ASTM D412) | |

| –Abrasion Resistance: <200 mm³ (ASTM D5963. Taber Wear) | |

| Thermal Resistance | –Service Temperature: -30°C to +120°C (intermittent 150°C) |

| –Thermal Stability: <15% weight loss at 120°C (24h, ASTM D573) | |

| Chemical Resistance | –Resistant To: Mineral oils, greases, hydraulic fluids, and dilute acids |

| –Limitations: Polar solvents (e.g., acetone), ozone, and weathering | |

| Key Applications | –Automotive: Fuel hoses, O-rings, and seals |

| –Industrial: Gaskets, conveyor belts, and oil-resistant rollers | |

| –Consumer: Gloves, footwear soles, and adhesive tape backing | |

| Processing | –Mixing: Two-roll mill (15–30 min, 40–60°C) or internal mixer |

| –Molding: Compression/injection molding (150–180°C, 5–20 MPa) | |

| –Curing: Post-cure (150°C, 2–4h) for compression set optimization | |

| Safety & Compliance | –MSDS: Non-flammable (flash point >200°C); avoid inhalation/skin contact |

| –Regulatory: REACH, RoHS, and FDA 21 CFR 177.2600 (food-grade variants) | |

| Storage | –Conditions: Cool (<25°C), dry, away from UV/ozone; shelf life 6–12 months |

| –Packaging: Polyethylene-lined bags (prevent moisture absorption) | |

| Quality Control | –Testing: Mooney viscosity (ML 1+4. ASTM D1646), compression set (ASTM D395) |

| –Certifications: ISO 9001 (manufacturing), ASTM D2000 (standard classification) |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

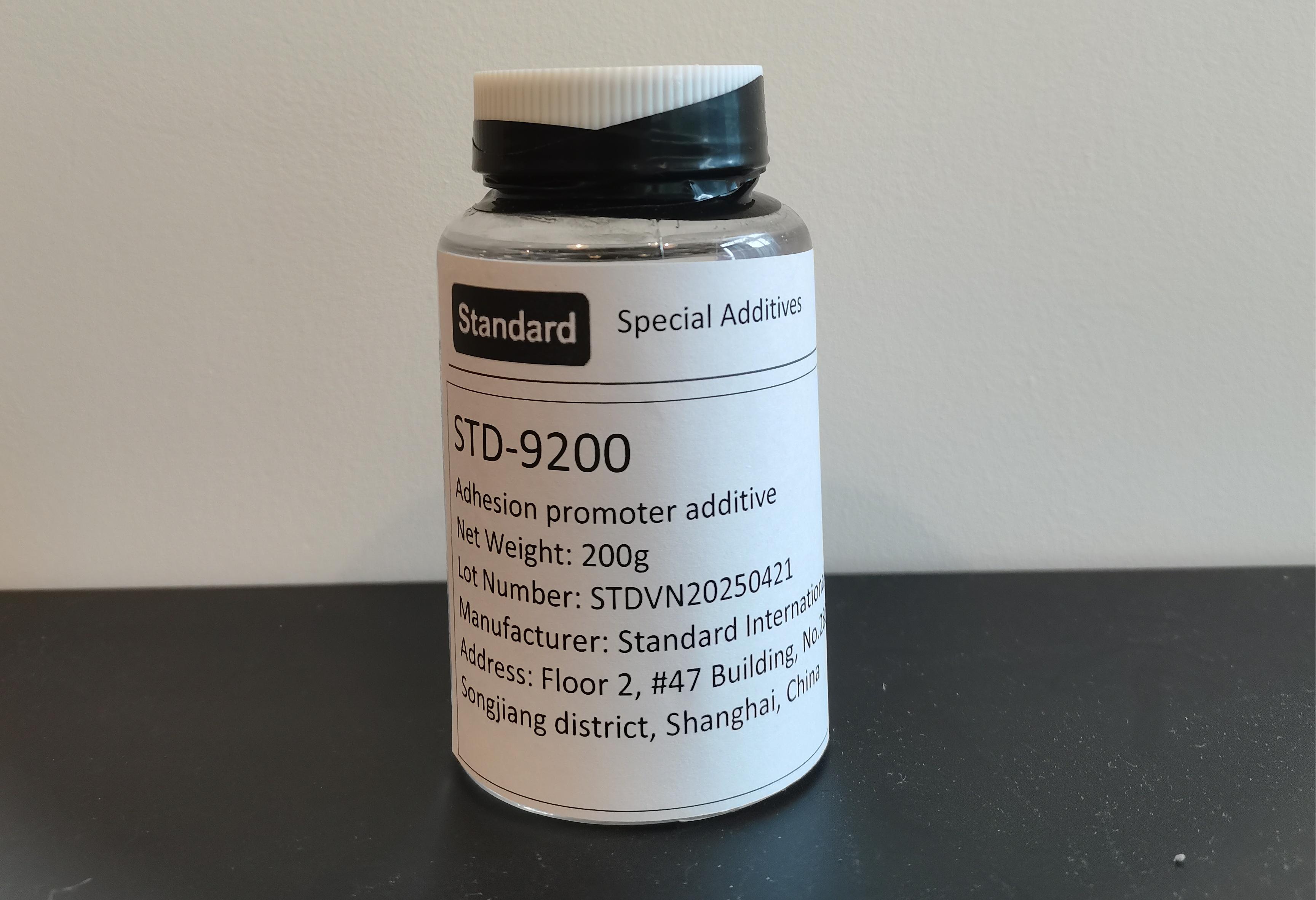

| STD-9200 Adhesion Promoter Additive | Technical Specifications ParameterDetails Composition Modified silane/titanate hybrid Appearance Clear, amber liquid Active... | |

| Quick cooling water purifier STD-19 | Quick cooling water purifier STD-19 is a cationic surfactant. It contains elements such as N, P and S, and has the functions of demulsification, co... | |

| Silicon Dioxide STD | Technical Data Properties Units Target Values(SpecLimits) Test results Silicon dioxide content (dry product) % ≥98 99.7 L... | |

| EpoxyPolyester Powder Coatings | Feature: -Good bond ability and mechanical performance -Smooth and glossy -Certified chemical resistance -Better heat resistance and light resi... | |

| Gray Matte Powder Coating | Key attributes ItemsInformation CAS No. 53808-41-6 Place of Origin China Main Raw Material EPOXY Usage Furniture Pai... |

Похожие товары

| Easy-cleaning Silicone-Modified Waterborne UV Resin | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... | |

| Water-based Soft-Touch Resin for Consumer Electronics | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... | |

| Conformal Coatings | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... | |

| Metalized & Laser Transfer coating | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... | |

| Hydrophilic coatings for Air Conditioner | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |