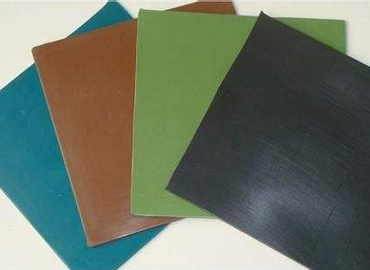

Perfluoroether rubber compound

Perfluoroether rubber is the most resistant material to high temperature and chemical solvents among all elastomer sealing materials. It is resistant to chemicals and corrosive media such as strong acids, strong alkalis, ketones, ethers, alcohols, esters, aldehydes, hydrocarbons, nitrogen-containing compounds and amino compounds, which are not resistant to ordinary rubber and fluororubber. Perfluoroether can be widely used in petrochemical industry, chemical industry, pharmaceutical industry, solvent equipment, aerospace equipment, nuclear energy industry according to various working environments and temperatures, especially in the extremely harsh environment of photolithography, chemical etching and chemical cleaning in the production process of semiconductors, which requires extremely high thermal stability and chemical resistance, and perfluoroether can play a great role.

| Category | Details |

|---|

| Composition |

–Base Polymer: Perfluoroether copolymer (FFKM, e.g., Kalrez®, Chemraz®) |

|

–Reinforcing Fillers: PTFE (10–30 phr), carbon nanotubes (optional) |

|

–Curing Agents: Peroxide (DCP, 1–3 phr) or ionic crosslinkers |

| Physical Properties |

–Hardness (Shore A): 55–90 (ASTM D2240) |

|

–Tensile Strength: 8–20 MPa (ASTM D412) |

|

–Compression Set: <25% (200°C, 70h, ASTM D395) |

| Thermal Resistance |

–Service Temperature: -25°C to +327°C (intermittent 350°C) |

|

–Thermal Stability: <5% weight loss at 300°C (24h, ASTM D573) |

| Chemical Resistance |

–Resistant To: Acids, bases, oils, fuels, steam, and plasma |

|

–Limitations: Molten alkali metals, fluorine gas |

| Key Applications |

–Semiconductor: Wafer processing seals, plasma chambers |

|

–Chemical Processing: Aggressive media seals and diaphragms |

|

–Aerospace: Rocket propulsion systems and fuel-resistant O-rings |

| Processing |

–Mixing: High-temperature internal mixer (>50°C) or two-roll mill |

|

–Molding: Compression/injection molding (200–250°C, 15–30 MPa) |

| Storage |

–Conditions: Dry, <25°C, away from UV/ozone; shelf life 12–18 months |

| Certifications |

–Regulatory: FDA 21 CFR 177.2400 (food-grade), SEMI F57 (semiconductor) |

Другие товары поставщика

|

|

Antimicrobial and Antiviral Powder Coating |

Product Introduction:

This product is formulated using special resins, curing agents, and specialized antimicrobial agents. It features high react... |

|

|

White Powder Varnish Vecodur VPPA White |

Product Information – VECODUR VPPA White

AttributeDetails

Product Form

Powder

Description

Powder for electrostatic applica... |

|

|

C5 inhibitor STD6 |

C5 inhibitor STD6 has the functions of anti-oxidation, anti-polymerization, cleaning and dispersing, and can effectively inhibit the scaling and ox... |

|

|

Epoxy Zinc-Rich Powder Coating |

Introduction

Product SegmentationApplication Fields

Epoxy Zinc-Rich Powder Coating

Wind power, transportation infrastructure, co... |

|

|

Yellow Wrinkle Color Powder Coating |

Introduction

Product Detail

Texture

Wrinkle

Color

RAL and PANTONE or customized

Surface Finis... |

Все товары поставщика

Похожие товары

|

|

Easy-cleaning Silicone-Modified Waterborne UV Resin |

Продавец: Guangzhou Human New Material Science and Technology Co., Ltd |

LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... |

|

|

Water-based Soft-Touch Resin for Consumer Electronics |

Продавец: Guangzhou Human New Material Science and Technology Co., Ltd |

Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... |

|

|

Conformal Coatings |

Продавец: Guangzhou Human New Material Science and Technology Co., Ltd |

The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... |

|

|

Metalized & Laser Transfer coating |

Продавец: Guangzhou Human New Material Science and Technology Co., Ltd |

Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... |

|

|

Hydrophilic coatings for Air Conditioner |

Продавец: Guangzhou Human New Material Science and Technology Co., Ltd |

A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |