UV-Cured Powder Coating

UV-Cured Powder Coating

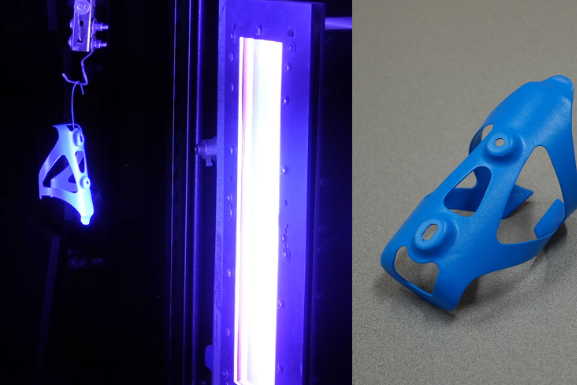

How can we coat heat-sensitive substrates effectively? UV-cured powder coatings provide the solution. Unlike traditional coatings that rely on high temperatures, UV-cured powder coatings utilize ultraviolet (UV) light to cure, making them ideal for heat-sensitive materials. UV-cured coatings are specifically designed to address the challenges of coating materials that deform or degrade under high temperatures, like MDF, plastics, and certain electronics.

What is UV-Cured Powder Coating?

UV-cured powder coatings are a type of powder coating that uses ultraviolet light for curing, rather than relying on traditional high-temperature ovens. The process involves applying the powder coating to the substrate and then using UV light to trigger the curing reaction. The unique feature of UV-cured powder coatings is their ability to cure at lower temperatures, typically between 100°C and 120°C, which makes them suitable for materials that are sensitive to heat.

The primary goal of UV-cured powder coatings is to provide an effective coating solution for substrates like MDF, plastics, paper, soldered components, and electronic assemblies—materials that would be damaged by the high curing temperatures required by conventional powder coatings.

The curing process for UV-cured powder coatings involves two stages:

Melting: The powder is melted with a brief application of low heat to form a smooth film.

UV Curing: UV light initiates a photochemical reaction that cross-links the coating, curing it quickly and solidifying the surface.

Advantages of UV-Cured Powder Coatings

Low Curing Temperature

UV-cured powder coatings are ideal for substrates that are sensitive to high heat, such as MDF, plastics, and other composite materials. These coatings can be cured at much lower temperatures compared to traditional powder coatings, making them applicable in industries where high heat would cause damage or deformation.

Compatibility with Heat-Sensitive Materials

As mentioned, the primary benefit of UV-cured powder coatings is their ability to coat materials like MDF and plastics, which cannot withstand the high temperatures required by traditional heat-cured powder coatings. This makes UV curing essential for industries that work with these substrates.

Faster Processing Time

UV curing is much faster than traditional thermal curing methods. Once the UV light is applied, the coating cures within seconds, reducing production time and increasing efficiency. This is particularly advantageous for industries that need to increase throughput and minimize downtime.

Energy Savings

By reducing the need for prolonged high heat, UV-cured coatings can lower energy consumption, which translates into cost savings over time. This makes the process not only more suitable for heat-sensitive materials but also more economical and energy-efficient in the long run.

Environmentally Friendly

UV-cured coatings release fewer volatile organic compounds (VOCs) and have minimal environmental impact. Since UV curing does not rely on solvents, it is a more eco-friendly option than solvent-based coatings.

Common Uses:

Drone manufacturing

Consumer electronics

Automotive manufacturing

Outdoor hardware and equipment

Sports products

In 3D printed assemblies, where multiple printed pieces fit together and need to match color perfectly

Use Cases

Use UV powder coating anywhere you need:

Vibrant colors

Perfect color consistency or color matching

Outdoor weather resistance

Surface smoothing

Sealed and protected surfaces

Production-level aesthetics

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Appliance Acrylic Resin Powder Coating | 1. Product Category Specifications Our diverse range of acrylic formulations is engineered to meet specific chemical and functional requirements: ... | |

| Brown Color Matte Powder Coating | Surface Finish Options Overview Powder type Epoxy-Polyester, Polyester Applications Exterior Industrial, Specialized Finish type Smooth Co... | |

| Pearlescent Powder Coating | Introduction Our pearlescent powder coatings deliver a soft, shimmering effect with outstanding durability—ideal for manufacturers seeking b... | |

| Gradient Powder Coating | Introduction We are a professional powder coating manufacturer with over 20 years of export experience, specializing in customized gradient powder... | |

| Industrial Protective Fluoropolymer Powder Coating | 1. Why Choose Fluoropolymer Powder Coatings? Fluoropolymer coatings are engineered for performance in the most demanding environments, offering a ... |

Похожие товары

| Easy-cleaning Silicone-Modified Waterborne UV Resin | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... | |

| Water-based Soft-Touch Resin for Consumer Electronics | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... | |

| Conformal Coatings | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... | |

| Metalized & Laser Transfer coating | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... | |

| Hydrophilic coatings for Air Conditioner | Продавец: Guangzhou Human New Material Science and Technology Co., Ltd | A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |