Development System of BMC Rotor Mould

At present, in the development process of BMC mold, the BMC material is thermosetting resin. In the process of mold heating and curing, because of the expansion performance of BMC compositematerial, the pressure in the mold cavity suddenly increases, which makes it difficult to demould the BMCcompoundproducts, and the products are difficult to separate from the mold. Especially some products with long straight surface can not separate from the mold, resulting in die scrap and product development failure.

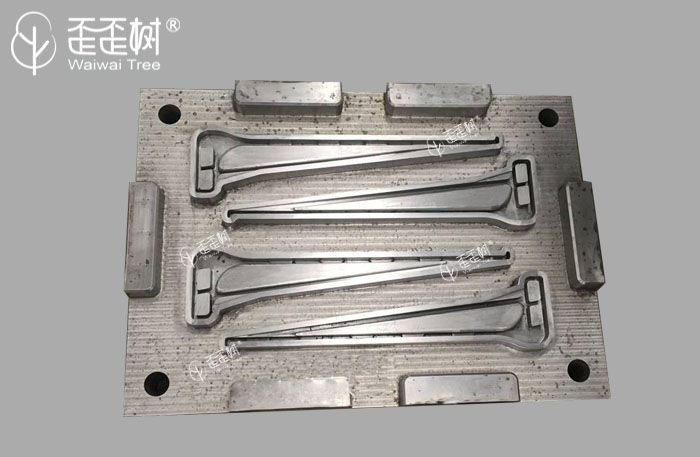

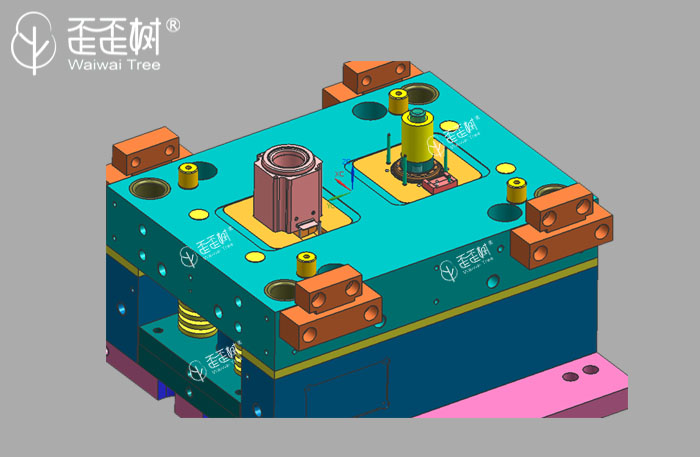

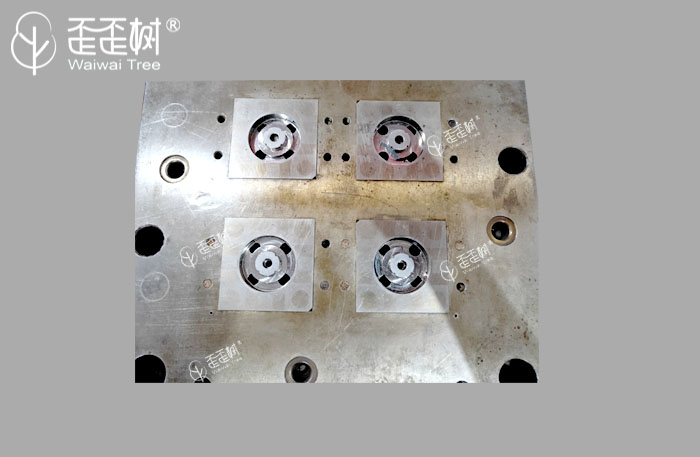

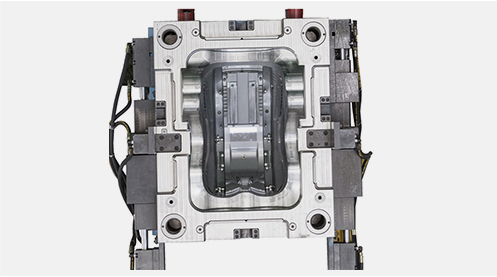

The BMC Rotor Mold can successfully complete the production process. Compared with the existing technology, it has the following advantages: there is a long straight surface product in the BMC rotor moulding, so it can not be separated from the mold, and it can be used when it can not set a large demoulding slope on the product surface. In the process of mold locking, the lock insert is locked up and down through the lock surface, so that the insert will have a fully fitted balance state, and the fit between the insert and the middle sleeve plate will leave a large space for fit clearance, which effectively prevents the die expansion during the injection molding process. When opening the die, the lock surface is removed and the insert is peeled off from the product quickly, so that the ejection production process can be completed smoothly and the stability of the whole die can be further improved.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Auto Parts And Accessories | Motor Mold Description Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the cross... | |

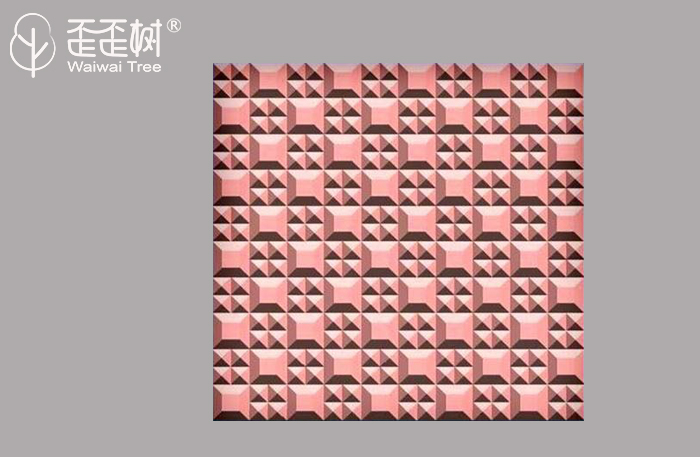

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safet... | |

| SMC Antenna Reflector Mould | The satellite earth antenna is the important earth satellite equipment to collect the weak signal from satellite and reduce noise to the lowest lev... | |

| BMC/SMC Molded Products | SMC, BMC thermosetting plastic products are produced by SMC and plastic smcmolding process. Types of BMC/SMC Molded Products BMC SMCMotor SM... |

Похожие товары

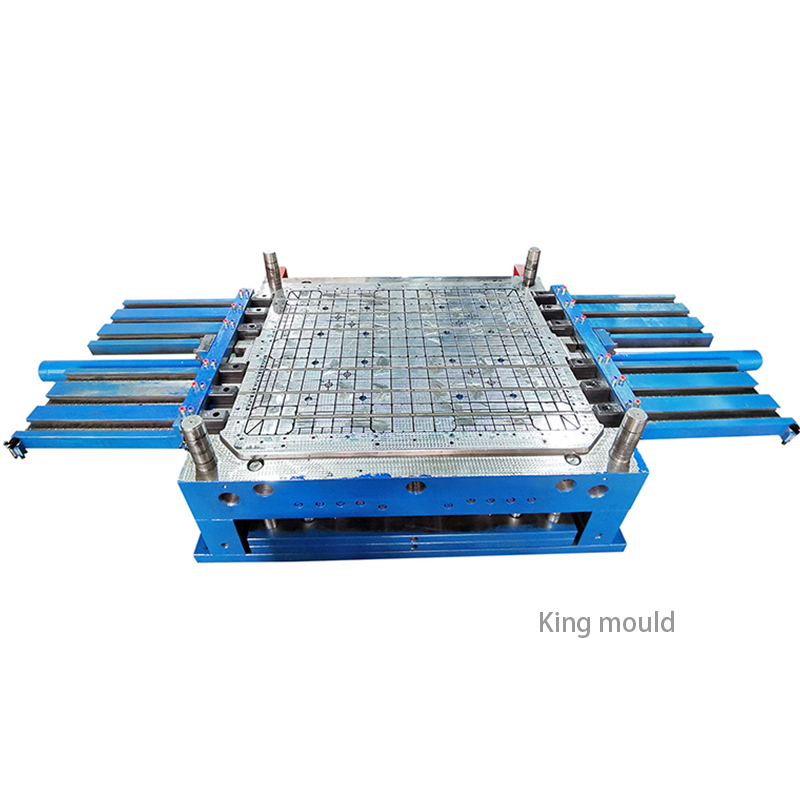

| Plastic Injection Lightweight Pallet Mould | Продавец: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Продавец: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Производство литьевых форм | Продавец: HANKING MOULD ENGINEERING LTD. | HanKing Mould имеет такие преимущества, как низкие затраты на рабочую силу, короткое время изгото... | |

| Car Seat Mould for Kids | Продавец: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Продавец: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |