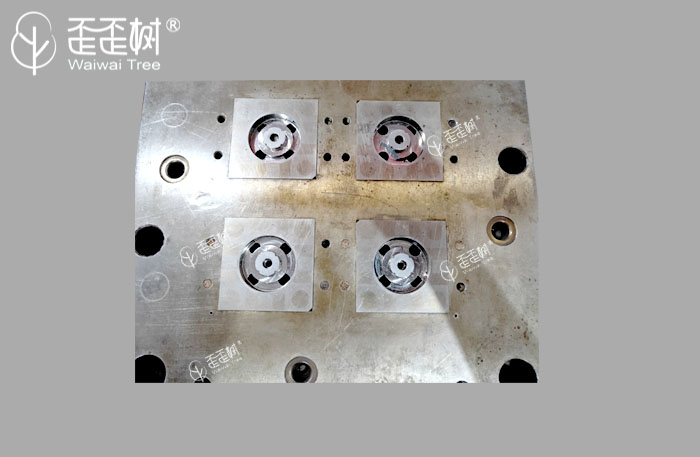

Development System of BMC Rotor Mould

At present, in the development process of BMC mold, the BMC material is thermosetting resin. In the process of mold heating and curing, because of the expansion performance of BMC compositematerial, the pressure in the mold cavity suddenly increases, which makes it difficult to demould the BMCcompoundproducts, and the products are difficult to separate from the mold. Especially some products with long straight surface can not separate from the mold, resulting in die scrap and product development failure.

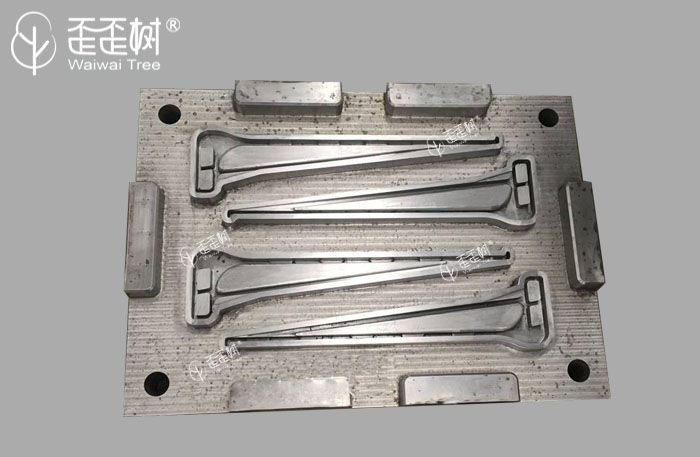

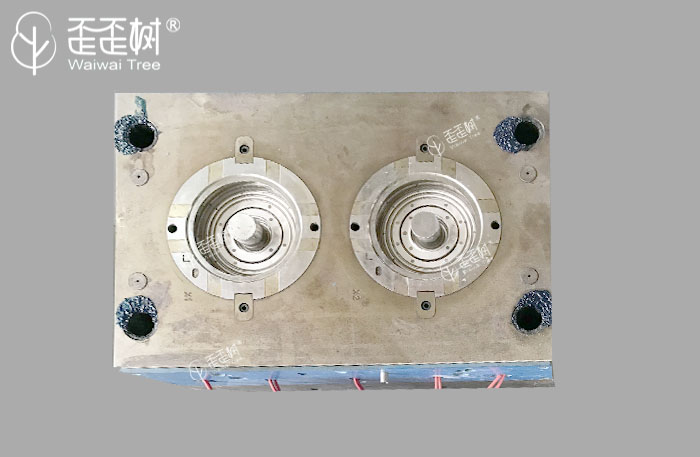

The BMC Rotor Mold can successfully complete the production process. Compared with the existing technology, it has the following advantages: there is a long straight surface product in the BMC rotor moulding, so it can not be separated from the mold, and it can be used when it can not set a large demoulding slope on the product surface. In the process of mold locking, the lock insert is locked up and down through the lock surface, so that the insert will have a fully fitted balance state, and the fit between the insert and the middle sleeve plate will leave a large space for fit clearance, which effectively prevents the die expansion during the injection molding process. When opening the die, the lock surface is removed and the insert is peeled off from the product quickly, so that the ejection production process can be completed smoothly and the stability of the whole die can be further improved.

Send product request

Other supplier products

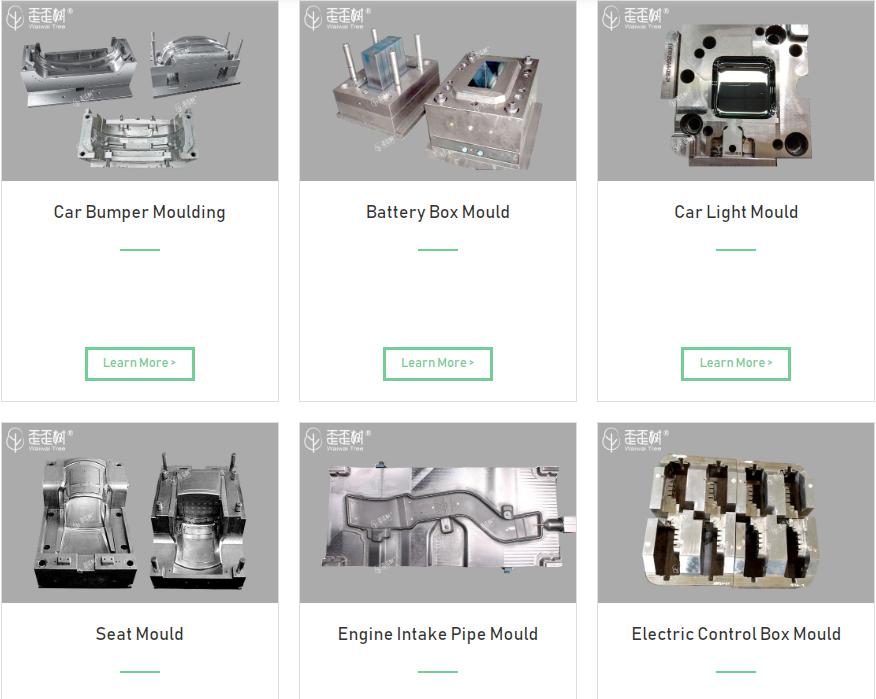

| Auto Parts Mould | Auto Parts Mould Features Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the cav... | |

| Principle Analysis of Over Moulding Technology for Injection Mold | In the past 10 years, over-mouldingtechnology has completely changed the aesthetic standards, design ideas and functional requirements of consumer ... | |

| Shell Moulding | Shell MouldingDescription Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner an... | |

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulation, bmc insulation. Typ... | |

| SMC Cable Braket | The BMCcompositeprecision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC moldinghave no waste, a... |

Same products

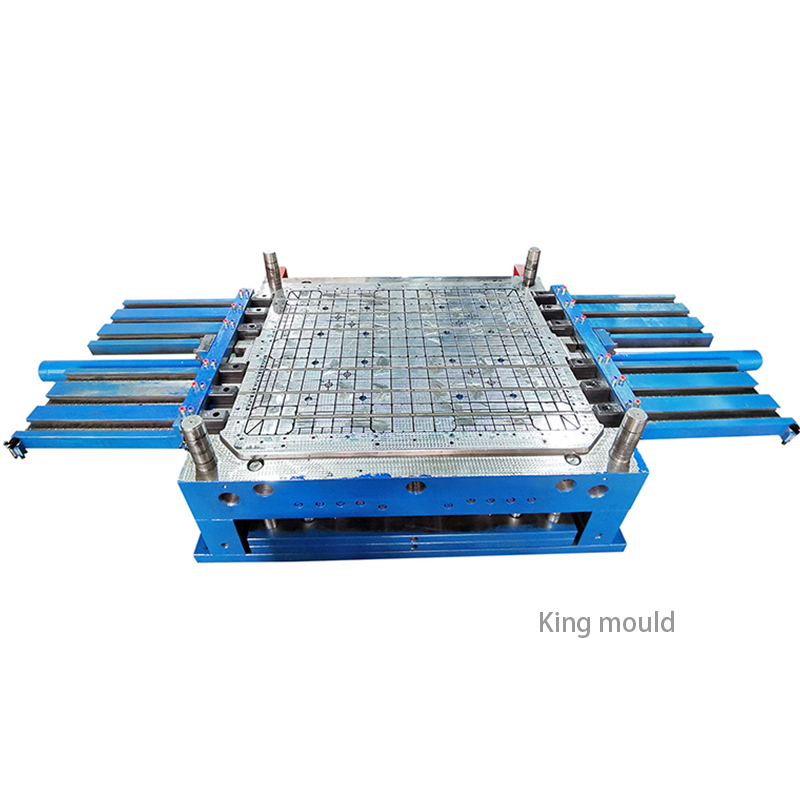

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

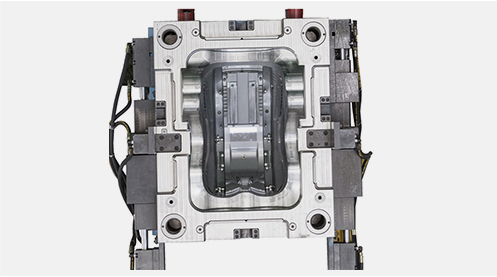

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |