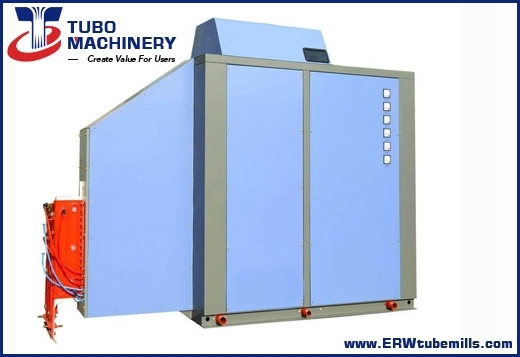

Slitting Line 1600x6mm

Slitting Line 1600x6mm

(1.0-6.0)mm×1600mm Slitting Line

The Slitter Line is used to slit the thin steel strip in coil into several narrow strips of certain size. The slit strips are then rewound into coils, for which welded pipes, cold-formed sections and presswork are manufactured.

The lines are composed of high-precision slitters with quick tooling change for slitter, tensioning device and recoiler. High-capacity recoilless . Extraction from coils without banding. Scrap baller or scrap choppers. Moving tensioning devices with incorporated leveling.

Advantages & Characteristics of our Coil Slitting Machine:

1.Weight of middle thick steel coils usually with weight up to about 30Tons, in this case, double mandrel uncoiler is necessary to load so heavy coils. Double mandrel decoiler can be made to three steps respectively for three kinds of international standard inner diameter coils Φ508mm, Φ610mm, Φ760mm. At the same time, Double mandrel decoiler can made to be double cones without steps that can support and decoil a wide range of different ID coils from Φ480-800mm for the special steel slitting machine.

2.There are one or two hole accumulators in the middle thick coil slitting line, which depends on MIN. thickness, slitting speed, etc factors. One pit accumulator always lies after slitter and before tensioner.

3.According to functions & solidity request of each steel slitter unit, we adopt suitable structure and use proper and enough material to make each steel coil slitting line unit.

4.Good material and precise sizes of disc knives, spacers and rubber rings on slitting shaft for our steel slitting machine can make sure little burrs, little cambers(±0.10mm/m), no stickiness to knives and precise slit width(+/-0.05mm).

5.Edge scrap reeler of our steel slitter uses torque motor, making sure evenly and synchronously wind edge scraps up.

6.To change disc knives fast, double steel slitter can be chosen. When one steel slitting machine is working, workers can install knives on the other slitter, then just exchange locations of two steel coil slitting line to continue work.

7.Double press rollers are installed on each equipment sequently following each hole accumulator, in case strip head falls in hole while feeding strip head through steel coil slitting line.

8.Coils separating & pressing-down bracket is installed on recoiler, hydraulically driven, press on recoiling block tight and automatically move up while recoiling diameter becomes bigger.

Working Process:

Coil-loading — Single-mandrel uncoiling — Coil-end-feeding & shoveling — Double-roller pinch feeding/three-roller leveling — End-cutting----Hole Accumulator 1 — Strip-aligning----Disk shearing — Scrap reeling — Hole Accumulator 2 — Pre-separator / Tensioner — Separating, Recoiling — Coils-discharging — Hydraulic control — Electric control

SPECIFICATIONS:

| - Material to be processed | Material of coils: HRC, CRC, GI, ST37, ST52, S235, S355 |

| - Yield strength | Max. 235Mpa |

| - Material thickness | 1.0~6.0mm |

| - Slitting width | 600~1600mm |

| - Slitting Motor | 110KW DC Motor |

| - Slitter shaft | Ф260 x 1650mm |

| - Slitting piece | Max.20 strips |

| - Recoiling Motor | 132KW DC |

| - Line Speed | Max.100m/min |

| - Raw coil weight | 30,000kg |

| - Min. slit width | 40mm |

| - Total power | 250kW |

We always design and make each line according to each customer's specific requirements, so each customer can buy his own well-content line from us.

For more information about coil slitting machine, please send us inquiry.

Hebei Tubo Machinery Co.,Ltd

Contact :Andy

Email:andy(at)erwtubemills.com

Web:

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Tube Mill Spare Parts | Tube Mill Spare Parts Product 1: Moulds / Toolings / Rollers Material: Cr12, Cr12MoV Product 2: Ferrite Rod Features: Improve weldin... | |

| Cut-to-length Line | Cut to Length Line Introduction:This is a kind of steel coil leveling equipment, integrating scissor and drop-type stackers. This metal cut to... | |

| High Frequency Welder | High Frequency Welder Solid State HF Welder Components Rectifier cabinet Inverter cabinet( with one set of air condition) ... | |

| Tube Mill 76mm | Tube Mill 76mm I. The technical flow of the production line{SteelTape}→Double-head un-coiler→Automatic Strip-head Cutter and welde... | |

| Slitting Line 1600x6mm | Slitting Line 1600x6mm (1.0-6.0)mm×1600mm Slitting Line The Slitter Line is used to slit the thin steel strip in coil into several narrow... |

Похожие товары

| NE-1525 Featuring Automatic Reset Battery Hydraulic Pipe Plumbing Tool | Продавец: Zhejiang Huaqi Information Technology Co., LTD | ● The automatic reset battery hydraulic pipe crimping tool is an industry- solution designed for ... | |

| STAINLESS STEEL SPIRAL WELDED PIPE PRODUCTION LINE | Продавец: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | The stainless steel spiral welded pipeunit adopts front-swing intermittent production, which is a... | |

| Push Ball Valve | Продавец: Zhejiang Carbo Bronze Co., LTD | Because the push to connect flanged bronze ball valve is designed and manufactured with a push ro... | |

| Hydrolysed Gelatine Powder | Продавец: Zhejiang Xinmei Biotechnology Co., Ltd. | Semix hydrolyzed/hydrolysed gelatin is the product of the hydrolysis of collagen by enzymes (acid... | |

| CARBON STEEL SEAMLESS PIPE | Продавец: "Ханнен" | Seamless Steel Pipe is made from a solid round steel‘billet’which is heated and pushe... |