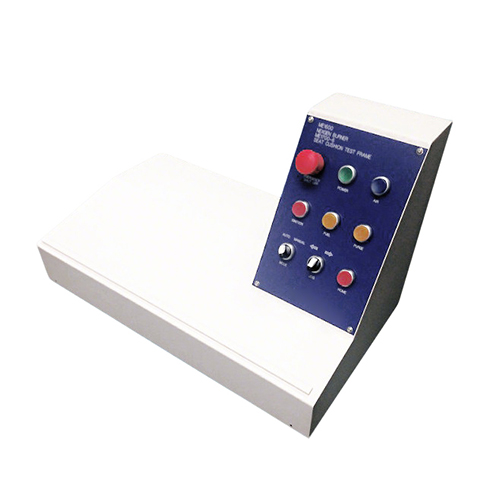

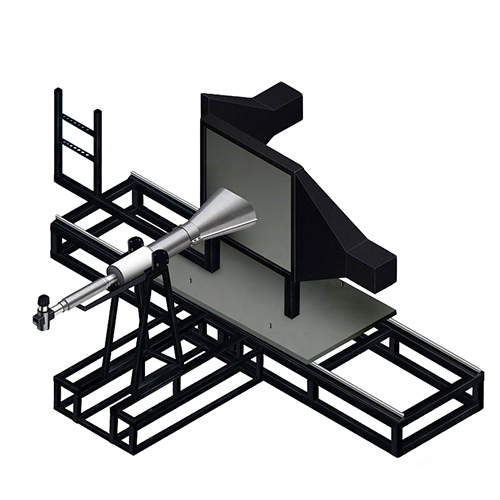

LGET-553 Aluminum Tube Eddy Current Flaw Detector

LGET-553 Aluminum Tube Eddy Current Flaw Detector Brief Introduction

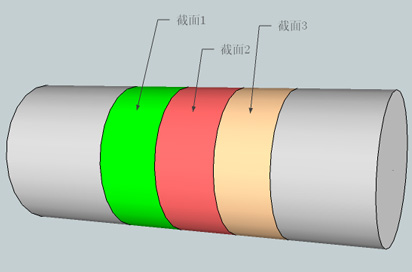

The aluminum tube is a type of non-ferrous metal which may have one or more closed holes which are thick and uniform in cross-section. It is widely used in electrical, agricultural, electromechanical and other industries. Therefore, when using aluminium tubes, we need to test the quality of the aluminium tubes.

The special physical properties of aluminum - high toughness and low density make it the material of choice for making water tanks. If there are visible holes and cracks in the raw materials that are invisible to the naked eye, and this raw material is also used in the production tank, it will eventually lead to the water tank. Leaking water, causing the entire water tank to be scrapped.

The structure of the aluminum tube is complicated, except for defects such as cracks and scratches on the surface. Various defects also occur in the interior of the aluminum tube. In the face of this complicated situation, the general flaw detector is unable to obtain accurate damage information. Our company has shown through many experiments that ECT eddy current testingis suitable for detecting defects of metal materials of various structures. The aluminum tube inspection equipmentcan effectively avoid the problem of unstable detection data caused by the special structure of the aluminum tube.

LGET-553 Aluminum Tube Eddy Current Flaw Detector Performance

|

Impedogram range |

5files adjustment |

|

Detection speed |

1~500m/min |

|

Frequency range |

100Hz-10MHz |

|

Gain |

0~99dB, step size 0.1dB |

|

Advanced filtering |

have |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

|

Phase rotation |

0-360 °step1 ° |

|

Sampling rate |

1~200000SPS adjustable |

|

Probe drive |

1%~100% adjustable |

Features of LGET-553 Aluminum Tube Eddy Current Flaw Detector

|

Synchronized alarm output controlled by an internal and external clock |

|

High precision end and end-t-tail signal removal |

|

High precision real-time and delayed alarm output |

|

Fast digital/analog electronic balance |

|

Memory track delay blanking function |

|

Real-time impedance plane display |

|

The instrument can match any probe |

|

remote automatic help system |

|

Chinese and English man-machine interface |

|

Non-equal amplitude phase/amplitude alarm domain |

|

Computer full digital parameter adjustment |

If you want to know more kinds of non destructive testing instruments, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 MFL Tank Floor Scanner Unique full modular structure, from the main body of the computer mechanism the handle ... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a lead... | |

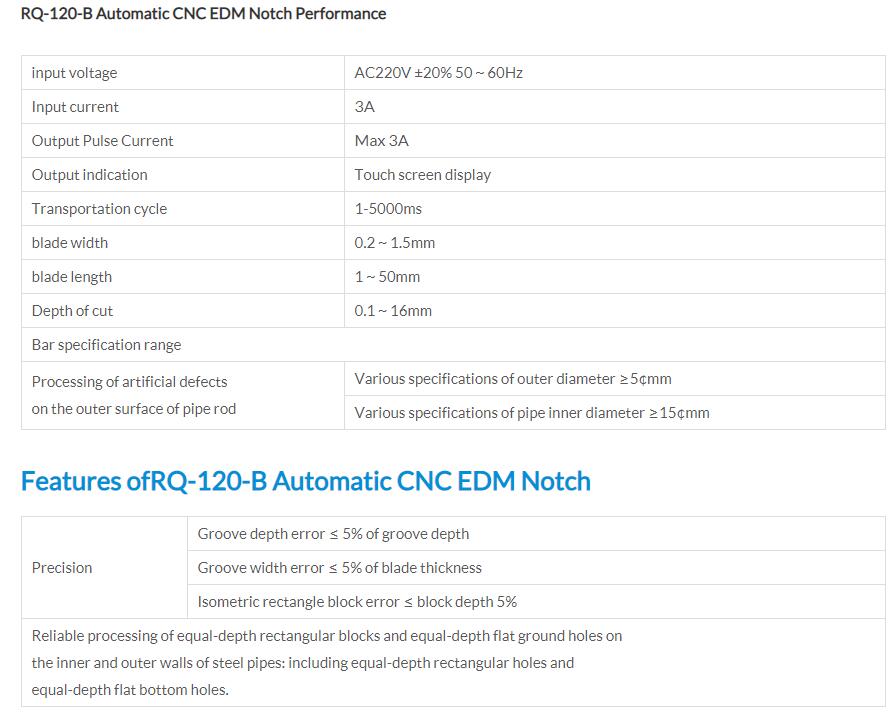

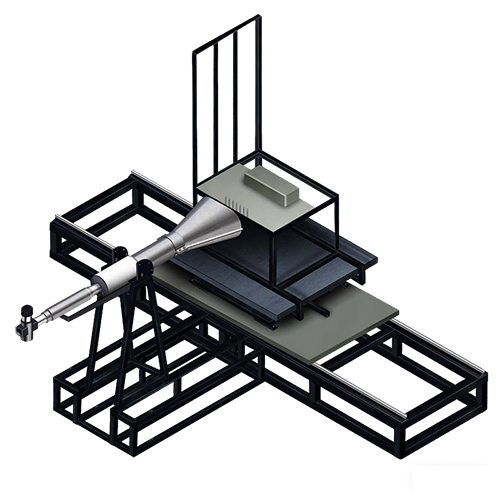

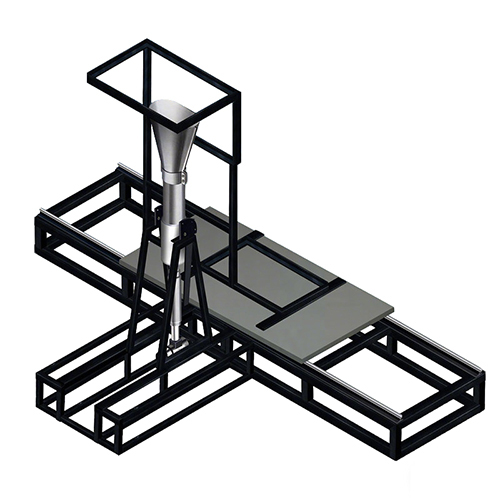

| Eddy Current Testing Equipment | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Wireless Transmission Steel Bar Ultrasonic Flaw Detector | Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external ... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |