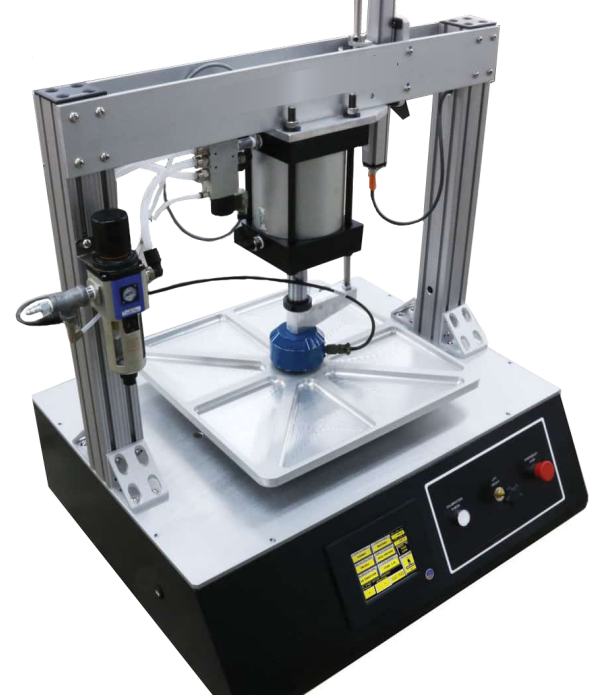

Air Intake Filter Performance Test System

The Air Intake Filter Test System is designed to evaluate the filtration performance, airflow characteristics, and dust holding capacity of air intake filters used in engines and industrial systems. The system fully complies with international standards such as ISO 5011, SAE J726, and GB/T 12485, providing accurate and repeatable results for both research and production quality control.

Applications

This test system is widely used for:

Performance evaluation of automotive air filters, industrial air filters, and engine intake systems.

R&D testing for new filter products and materials.

Quality inspection and certification by third-party laboratories.

Comparison and validation between domestic and international filter brands.

Conforming Standards

The system meets multiple global standards:

ISO 5011: Inlet air cleaning equipment for internal combustion engines and compressors.

SAE J726: Air cleaner test code for automotive and diesel engine filters.

GB/T 12485: Test methods for air cleaners used in internal combustion engines.

ISO 12103-1: Test dusts (A2 Fine and A4 Coarse) used for efficiency and dust holding capacity evaluation.

Key Test Procedures and Parameters

1. Restriction and Differential Pressure Test

Purpose: Measures resistance variation at different airflow rates to generate the pressure drop-airflow curve.

Method: Five flow rate points (50%–150% of rated flow) are selected; corresponding pressure drops (ΔP) are recorded.

Application: Evaluates airflow capacity and ensures the filter does not excessively restrict engine intake.

2. Initial Efficiency Test

Purpose: Determines the filter’s ability to capture dust particles at the start of operation.

Method:

Uses A2 Coarse or A4 Fine dust.

Introduces either 20 g of dust or a mass equivalent to six times the rated airflow (m³/min).

Calculates efficiency based on dust captured by the test filter and absolute filter.

Application: Assesses initial filtration performance of new filters.

3. Full-Life Efficiency Test

Purpose: Measures filtration efficiency over the filter’s entire service life.

Method:

Dust is fed continuously until the filter reaches its final restriction (e.g., 2.5 kPa).

Cumulative filtration efficiency is calculated throughout the process.

Application: Simulates real-world filter lifespan and clogging behavior.

4. Incremental Efficiency Test

Purpose: Evaluates filter performance at multiple loading stages.

Method: Efficiency is measured at 10%, 25%, and 50% of the pressure drop difference between the initial and final restriction.

Application: Helps analyze how filtration efficiency evolves over time.

5. Dust Holding Capacity Test

Purpose: Determines total dust mass retained in the filter before reaching the final restriction.

Method: The filter is weighed before and after testing to calculate total dust capacity.

Application: Evaluates filter longevity and maintenance intervals.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

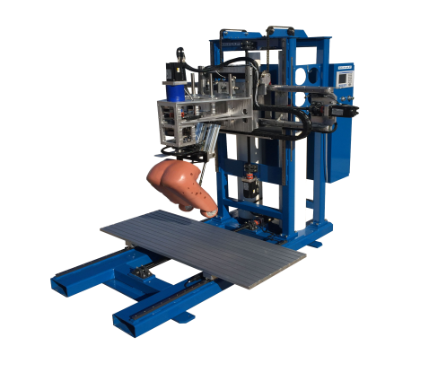

| Seat Ingress/Egress Simulation Tester| Testing Equipment | The True Body Weight Ingress/Egress Tester is a specialized machine designed to evaluate either a complete automotive seating system or individual ... | |

| Reciprocating Wear Tester | Standards ASTM F2496: Scratch hardness and adhesion testing for prints/coatings. ISO 1518-1 & -2: Scratch resistance determination for paints... | |

| BS 5852 Combustion Tester | BS 5852 combustion test equipment is mainly used to determine the flame retardant properties of soft furniture. It’s widely and conveniently ... | |

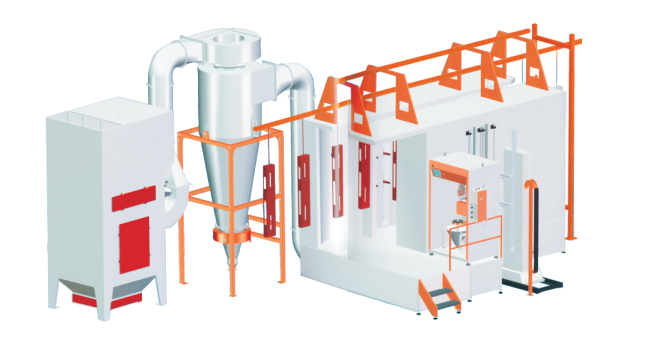

| Sandwich-Type Quick Color Change Spray Booth | Our Powder Coating Booths with integrated cyclone systems are designed to maximize powder recovery, reduce waste, and ensure a clean, efficient coa... | |

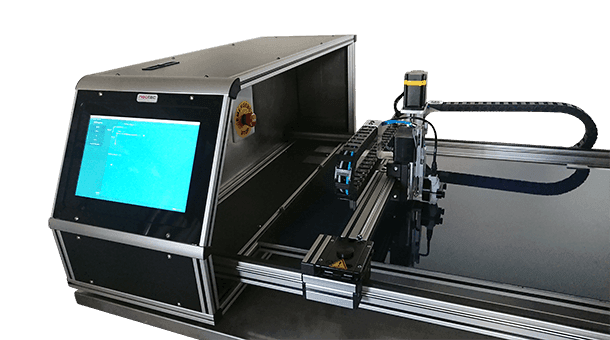

| Coating Thickness Gauge | The Coating Thickness Gauge is a high-precision contact-type thickness measuring instrument designed for accurate determination of thickness for fi... |

Похожие товары

| Air Intake Filter Test System | Продавец: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

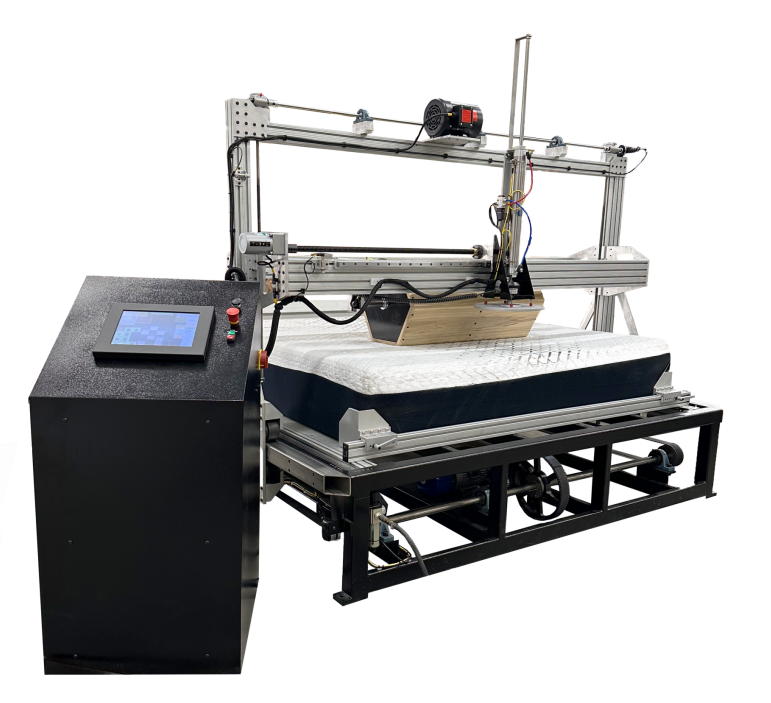

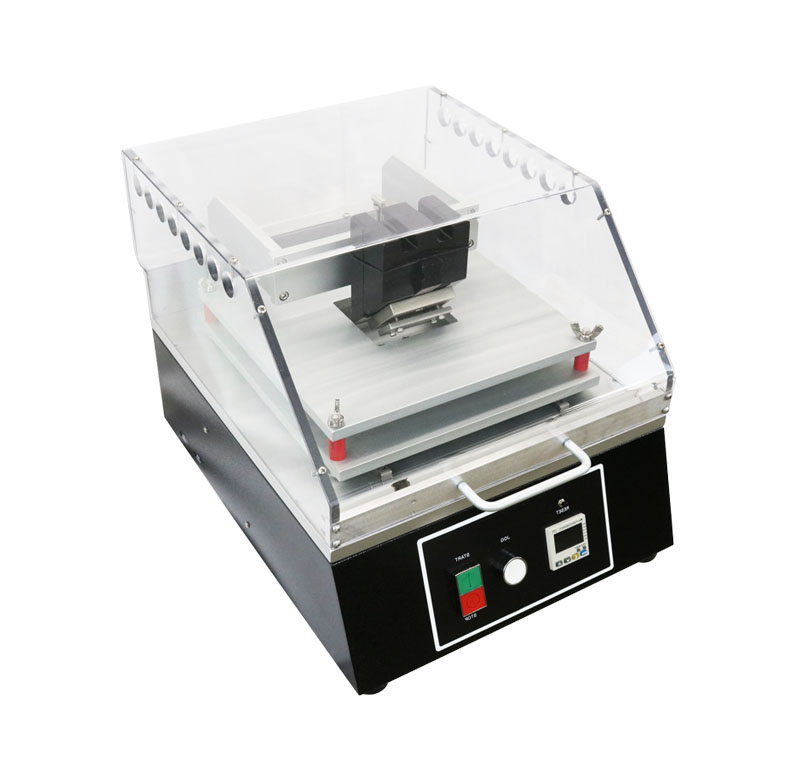

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Продавец: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Продавец: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Продавец: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |