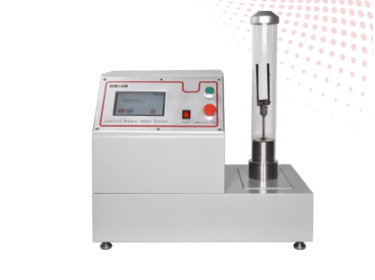

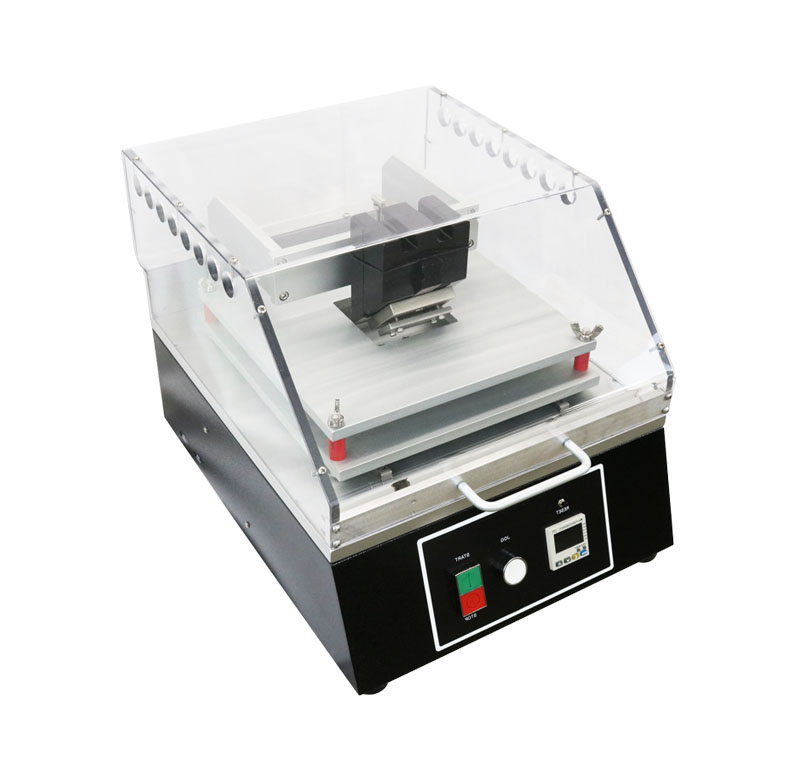

Oxygen Index Tester - lab instrument

Limiting Oxygen Index Tester The oxygen index of the material refers to the minimum oxygen concentration that can maintain the combustion of the material in the mixture of nitrogen and oxygen.At an appropriate oxygen concentration, the material is just right to ignite and burn.By controlling the value of oxygen concentration, this instrument can observe the combustion characteristics of samples one by one under different oxygen concentrations, so as to determine the ultimate oxygen index of samples.Good repeatability of experimental data can help manufacturers effectively control production and test product performance.

1. The Limiting oxygen index tester is used to measure the ultimate oxygen index of solid materials such as textiles, plastics, laminates, foams, films, etc. It can be used to evaluate the combustion performance under specified conditions, so as to guide the research and development of materials and provide data basis for the acceptance of products, new material R&D and product quality acceptance.

2.Sample fixed vertically in the transparent combustion cylinder with the upward flow of oxygen, nitrogen gas mixture in , lit the top of the sample, observing the combustion characteristic of sample, comparing the sample continuous burning time or sample combustion length with the given limit value. through a series of experiments under different oxygen concentration, measured the minimum oxygen depth value for maintaining combusion expressed as a percentage of oxygen, simple operation, easy to use, high efficiency.

Standards compliant

GBT 2406.1 Plastics Test of burning behaviour by oxygen index-Part 1: guideline;

GBT 2406.2 Plastics Test of burning behaviour by oxygen index -Part 2: Indoor-temperature test;

GBT 5454 Textiles Performance test of burning by oxygen index;

GBT 10707 Rubber Performance test of burning behaviour;

ISO 4589-2 Plastics Test of burning behaviour by oxygen index -Part 2: Indoor-temperature test;

ASTM -- D2863 Standard Test Method for Measuring the Minimum Oxygen Concentration of material combustion which is similar to plastics material (Oxygen Index);

IS0 4589-3 (Please inquire separately for the apparatus for the

ISO 4589-2 " Plastics -- Determination of burning behaviour by oxygen index -- Part 2: Ambient-temperature test”

NES 714, EN 45545-2,JIS 7201, BS 2782. etc.,

Major Features

Imported sensors

Imported Paramagnetic oxygen concentration sensor with high precision and stable performance.Real-time detection of oxygen concentration with PLC precise control so that can adjust the oxygen concentration through the airflow.

Flexible fixture design

The fixture is made of refractory and stainless material, which can resist high temperature and rust.It can hold various samples.By replacing the sample holder, the sample requirements of different characteristics can be fulfilled.

Linited Oxygmn Indes Testet

Intelligent touch operation 7-inch color screen, intelligent touch, multi-touch operating system, convenient operation, multi-language display, switching between

Chinese and English.Simplified operation interface, easy to operate

Quick change structural design

The test tube of this instrument which is made of high temperature resistant transparent glass combing with the base adopts quick change design to clearly observe the combustion situation in the test. Moreover, it is easy to clean after the test. The stainless steel base can avoid the influence of various corrosion on the test data, and its service life is long.

Field Application

This instrument measures the minimum oxygen volume percentage concentration at just required for maintaining combustion of the polymer.it is suitable for a wide range of materials by changing the sample fixture used in a variety of mechanical properties of the sample.lt can be used for the determination of burning performance of plastics, rubber, fiber, foam, film, textile and wood.

It is applicable to the performance verification of new products, quality control of the production department, and the of material properties for the third-party testing organization, the product performance verification laboratory, and the quality and technical supervisiondepartment, etc.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

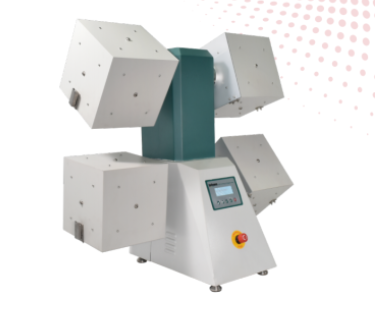

| Fabric ici pilling and snagging box | Applications A universal pilling and snagging tester drives system to rapidly repeat pilling or snagging on fabrics to generate normal wear on sam... | |

| Medical Face Mask Differential Pressure Tester | Application The Medical Face Mask Differential Pressure Tester is applicable to breathability evaluation across the following industries and produ... | |

| Hydraulic Oil Precision Filter Tester | 1. Applications The hydraulic oil filtration unit is designed to purify and maintain the cleanliness of hydraulic and lubrication systems across v... | |

| Vacuum cleaner filter efficiency test equipment | The vacuum cleaner filter efficiency test equipment primarily employs a self-developed control system, coupled with imported laser particle countin... | |

| Cone Calorimeter / Cone calorimetric test equipment | The Cone Calorimeter is widely used to evaluate fire performance of materials and products under controlled heat-flux exposure. It provides accurat... |

Похожие товары

| Air Intake Filter Test System | Продавец: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Продавец: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

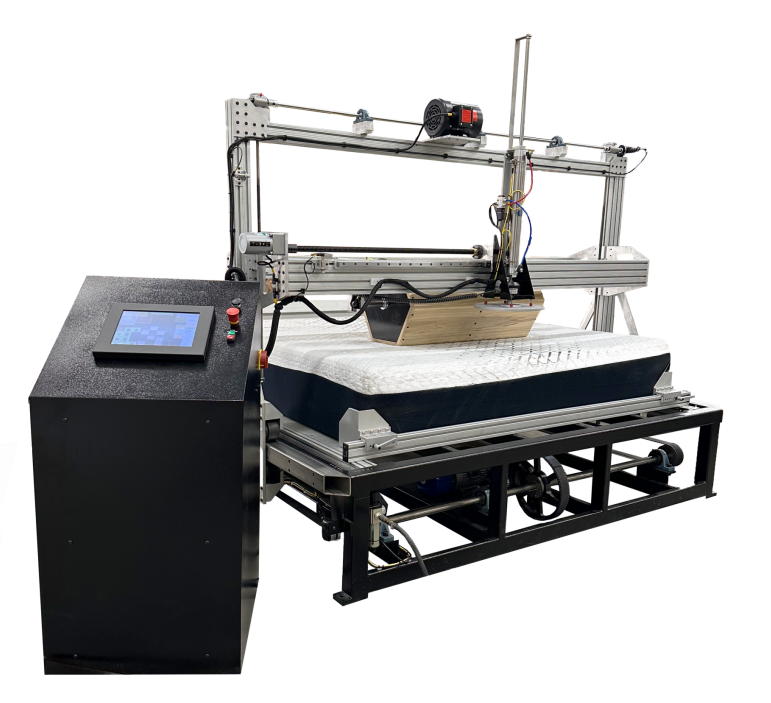

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Продавец: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

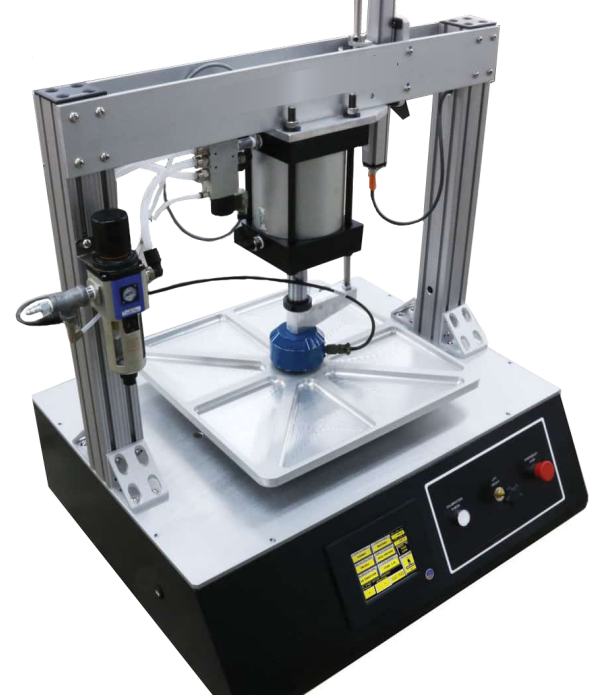

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Продавец: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |