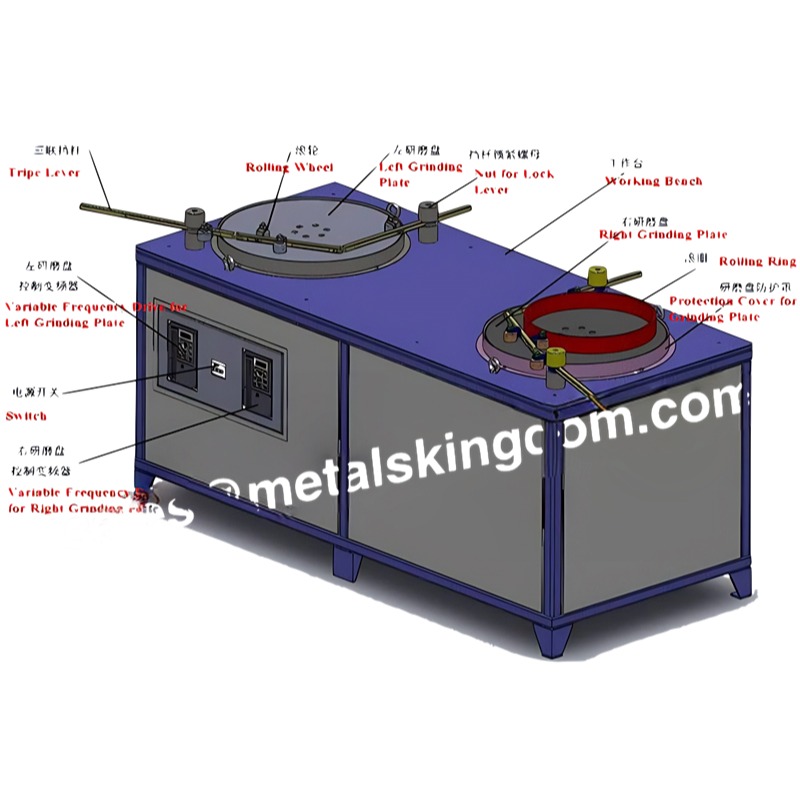

DN25-300 mm ,Stationary Valve Core Grinding Machine Stationary Valve Grinding Machine

Feature:1、Stationary, more stable and durable2、double station design,Easy to operate, higher efficiency

1)diameter of Grinding disc: Dia500mm

2)Scope of Grinding:Dia25-Dia300mm

3)Quantity of grinding disc:2 pcs

4)Application : valve core of plane globe valve, gate valve .

5) Motor Power:1100W,Double motor.

6)Speed regulation mode:Variable frequency stepless speed regulation

7)Power supply: 220 V/50Hz

8) motor power: 1100W x2=2.2kw double motor

Stationaryvalve grinding machineis suitable for the valve disks of gate valves and globe valves,it is widely applied in coal-fired power petrochemical steel metallurgical paper and other industriesFeature:1、Stationary, more stable and durable2、Double operating position design,Easy to operate, higher efficiency

1)diameter of Grinding disc: Dia500mm

2)Scope of Grinding:Dia25-Dia300mm

3)Quantity of grinding disc:2 pcs

4)Application : valve core of plane globe valve, gate valve .

5) Motor Power:1100W,Double motor.

6)Speed regulation mode:Variable frequency stepless speed regulation

7)Power supply: 220 V/50Hz

8) motor power: 1100W x2=2.2kw double motor

1.Connect the 380V power supply and turn on the total power supply.

2.Before starting the equipment, check whether there is any foreign body around the grinding disc and deal with it.

(1) Device startup key: RUN Device stop key: STOP Forward and Reverse conversion key: JOG

(Note: when the forward and reverse conversion is done, the position of the triple lever should be adjusted accordingly).

Speed adjustment: knob on the panel rotation adjustment or up and down key adjustment.

(2) Other key suggestions should not be adjusted so as to avoid confusion.

(1) Before grinding the spool, adjust and fix the triple lever according to the size of the spool, and install the roller assembly on the triple lever, adjust the position and press firmly. Apply the corresponding abrasive grout on the grinding plate. (see grinding process)

(2) Grinding and repair of round spool.

The spool is placed in the middle of the angle between the three retaining bars and contacts with the roller to start the equipment for grinding. Or put the spool roller between the angle of the triple bar and contact with the roller, put one or more spools into the roller, start the equipment for grinding.

(3) Grinding of Gate valve spool:

Place the spool roller between the angle of the triple lever and contact the roller. Place one or more spools in the roller and start grinding.

(4) Hand held grinding:

The small spool with less damage will put the spool on the grinding disc, and start the equipment to carry out grinding by hand.

(5) the left and right two lapping plates are controlled by two transducers on the left side and the right side respectively, and the operation mode is the same.

The abrasive paste with different sizes should be replaced according to different grinding needs. The abrasive paste is stirred and coated on the abrasive plate with machine oil. Before grinding, the high point burr on the spool should be removed before grinding.

1)Rough grinding:

Choose 60 -120# abrasive paste to remove defects such as groove marks, pits, scratches, etc.

2).Fine grinding:

Grinding around 240# or so is used to remove minor scratches.

3). Finish grinding:

More than 400 #grinding paste is used to finish the polishing.

Valve Polishing Machine, Stationary Valve Core Grinding Machine, Gate Valve Grinder Factory

Hot Sale Various High Quality Valve Grinder, Valve Test Bench, Pipe Beveling & Cutting Machine. The portable & Stationary Valve Grinding Machineis suitable for Gate Valve, Globe Valve, Safety Valve. As fames China Valve Seat grinded Machine, High quality and factory price will give you.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| M-100 Portable Gate Valve Grinding Machine | M-100 Portable Gate Valve Grinding Machine Technical ParameterApplication:Cone globe valve seat,Flat Globe valve seat.Grinding scope:Cone globe ... | |

| MT-1200X Stationary Valve Core Grinding Bench | MT-1200X Stationary Valve Core Grinding Bench Stationary valve grinding machine is suitable for the valve disks of gate valves and globe valves,... | |

| MJ-400 Portable Valve Grinding and Lapping Machine for Relief Valve | MJ-400 Portable Valve Grinding and Lapping Machinefor Relief Valve 1)grinding diameter: Dia118-Dia450mm 2)used for valve seat of plane globe va... | |

| MZ-250 Portable Gate Valve Grinding Machine | MZ-250 Portable Gate Valve Grinding Machine Portable Valve Grinding and Lapping Machine For Gate Valves Technical indicators Applicstion:Gate Va... | |

| DN100-400mm 4\ | DN100-400mm 4"-16" MJ400 Portable Globe&Relief Valve Grinding Machine 1)grinding diameter: DN100-400mm( 4"-16" ) 2)Suitable for valve seat ... |

Похожие товары

| 3 Inch Ceramic Bond Hybird Transitional Polishing Pads For Concrete | Продавец: Xiamen ChinShine Industry and Trade Corporation | – Available Grits: 30, 50, 100, 200,400. – Use wet or dry. Pad Materials –... | |

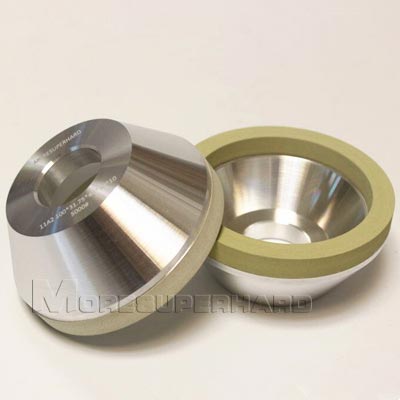

| 11A2 Стеклокерамический алмазный круг для шлифования инструментов PCD | Продавец: Henan Moao superhard material | Применение стеклокерамического алмазного круга для Pcd Специально для черновой, средней, получист... | |

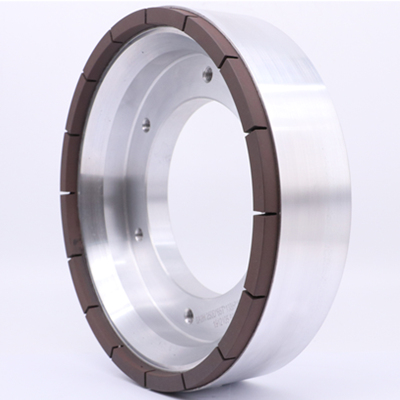

| Колеса из смолы для стекла | Продавец: Henan Moao superhard material | Применяемые машины алмазных кругов по смоле Станок для обработки прямой кромки стекла, станок для... | |

| Dental milling burs | Продавец: Jinrui (Гуандун) Новые материалы Co., Ltd. | Product Advantages: Good wear resistance. 2. Complete product range, suitable for all kinds of... | |

| Карбонит-режущее колесо, связывающее смолу | Продавец: Хэнань Моre Superhard матэрыялы Лтд | Карбонит-связыватель (лезвие для резки) обладает свойствами вертикальных потерь, которые эффектив... |