20 - 63mm Ppr Pipe Fittings Welding Machine

20/63mm Ppr Pipe Fittings Welding Machine

Brief introduction of the socket fusion tools

There are 2 series with different size and operation for meeting different customer’s requirement .

RJQ series are based on the standard and regular hand-held socket welder with a new controller for overheat protection and easy operation.

Digital series of ZRJQ models add a digital controller and screen for improving the accuracy of the heating temperature. The temperature range can set as demand of different plastic pipes & fittings, required fusing temperature can fix and display on the screen, environment temperature will be adjusted and updated automatically, over-temperature will be alarmed automatically and etc. This provides a more excellent fusing result.

Basic Parameter:

| DIGITAL SOCKET FUSION WELDER 63MM | |

| Rated voltage: | 220V/110V |

| Rated frequency: | 50Hz/60Hz |

| Rated power: | 800W |

| Working temp: | 200-279°C |

| Temp tolerance: | ≤5°C |

| Warning temp: | 295°C |

| Welding range: | 20,25,32,40,50,63 mm |

| Application: | PPR,PE,PB |

| Net weight | 1.8KGS |

| Machine dimension : | 370*125*50(mm) |

| QTY/CTN | 2SETS |

| G.W: | 20.5KGS |

| MEAS: | 460*265*265(mm) |

Comparison:

|

Model |

RJQ-63 |

ZRJQ-63 |

|

Difference |

Socket |

Digital Socket |

|

Working Temp |

260°C |

200-279°C |

Accessories:

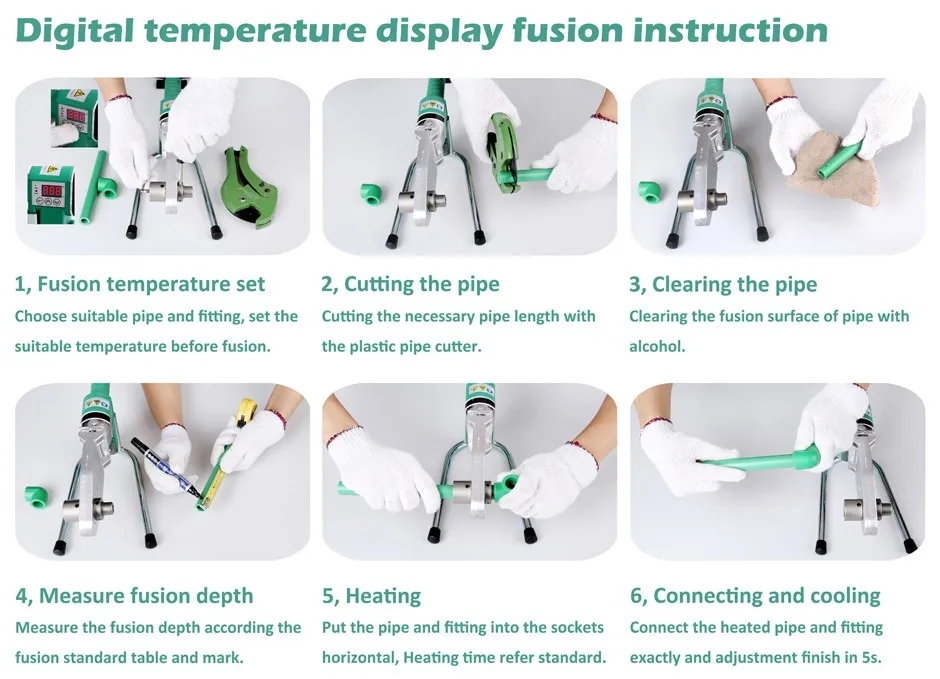

How To Use It:

Welding Sockets & Spigots

|

Specifications of pipes (φ) |

Internal diameter of concave head--- Spigots (φ) |

Internal diameter of convex head---Sockets (φ) |

Heat-fusing depth

|

|||

|

A |

B |

A |

B |

A |

B |

|

|

16 |

16.04 |

15.84±0.04 |

15.54 |

15.44±0.04 |

13 |

13 |

|

20 |

20.05 |

19.78±0.04 |

19.53 |

19.38±0.04 |

14 |

14 |

|

25 |

25.04 |

24.77±0.04 |

24.51 |

24.32±0.04 |

15 |

16 |

|

32 |

32.03 |

31.75±0.04 |

31.50 |

31.26±0.04 |

16.5 |

18 |

|

40 |

40.02 |

39.76±0.04 |

39.48 |

39.20±0.04 |

18 |

20 |

|

50 |

50.02 |

49.68±0.06 |

49.46 |

49.19±0.06 |

20 |

23 |

|

63 |

62.99 |

62.60±0.06 |

62.46 |

62.10±0.06 |

24 |

27 |

|

75 |

74.91 |

74.59±0.06 |

74.32 |

74.00±0.06 |

26 |

31 |

|

90 |

89.92 |

89.57±0.06 |

89.33 |

88.93±0.06 |

29 |

35 |

|

110 |

109.88 |

109.49±0.06 |

109.29 |

108.80±0.06 |

32.5 |

41 |

|

125* |

124.70 |

|

124.00 |

|

35 |

|

|

140* |

139.65 |

|

138.85 |

|

39 |

|

|

160* |

159.50 |

|

158.60 |

|

42 |

|

Suitable for butt welding of plastic pipes and / or fittings made of PE,PP, and PVDF in worksite or workshop.

1.Quick, efficient and professional response within 24 hours.

2.15 years manufacturing experience in plastic pipe&fitting field.

3.Reasonable price and shoter production cycle.

4.Technical support and solution by chief engineer.

5.Strict quality control system and team

6.Full range of pipe&fitting products for choice

7.OEM or ODM services both availiable for our company

8.Accept sample order before mass order

9.On-time delivery,and 24 hour after-sales service

Q1: Do you accept sample order?

A: Yes sure, please contact us for details.

Q2: How about your after-sales service?

A:We offer promote technology support for all problems and questions. If any parts broken or does not wor under normal operating,we are free to provide.

Q3: How about warranty period?

A: Guarantee period:24 months.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| SWT-MAT2 Tarpaulin Tape Welder | SWT-MAT2 Tarpaulin Tape WelderVoltage: 220VPower: 4200WFrequency: 50/60HzTemperature: 20-620 ℃ Adjustable ContinuouslyWelding Speed: 1.0-10.0 m/min... | |

| SWT - NS800D HDPE PVC geomembrane overlap plastic melting welding machine | Application SWT - NS800D HDPE PVC geomembrane overlap plastic melting welding machine Brief Introduction Geomembrane welder is a... | |

| Suspending Jig for Socket Fusion | Suspending Jig Connect Type:Socket Fusion Fix range:20-63mm For PPR PVDF PE pipe and fittings Measure:43*41*58cm Package:1pcs Alloy Box G.Weight:8k... | |

| Termofusao Welding Machines | ||

| hot selling SWT-MA630 HDPE pipe fitting fabrication machine | Features CNC Fitting Fabrication Machine: Versatile, Affordable and Intelligent CNC fitting fabrication machine is designed to fa... |

Похожие товары

| Паяльная паста MECHANIC 10 мл для пайки SMT-компонентов на печатных платах мобильных телефонов | Продавец: Phonefix | Паяльная паста MECHANIC в шприце (Sn63/Pb37) подходит для ремонта BGA-компонентов и SMT-компонент... | |

| YCS M.Y 140/160/183/199°C Solder Paste for Phone PCB IC Repair | Продавец: China PHONEFIX Technology Co., Ltd | Описание продукта Высокотемпературная паяльная паста YCS M.Y-XJ01 для пайки при температуре 140&... | |

| Паяльная станция MECHANIC T210 SE с цифровым дисплеем для точного ремонта печатных плат | Продавец: Phonefix | Паяльная станция MECHANIC T210 SE мощностью 50 Вт с цифровым дисплеем и термостатическим управлен... | |

| SUNSHINE SS-6604 SS-6605 Soldering Smoke Purifier Fume Extractor | Продавец: China PHONEFIX Technology Co., Ltd | Описание продукта Очистители дыма SUNSHINE SS-6604 и SS-66045 подходят для таких отраслей, как ре... | |

| Флюс-паста MECHANIC M35 для ремонта материнских плат телефонов | Продавец: Phonefix | Флюс-паста Mechanic M35 10 см3 отличается высокой активностью (98%). Эта высокоэффективная синерг... |