FITZ Growing Line growing line system pipe and shells growing line system

FITZ Growing Linegrowing line system pipe and shells growing line system

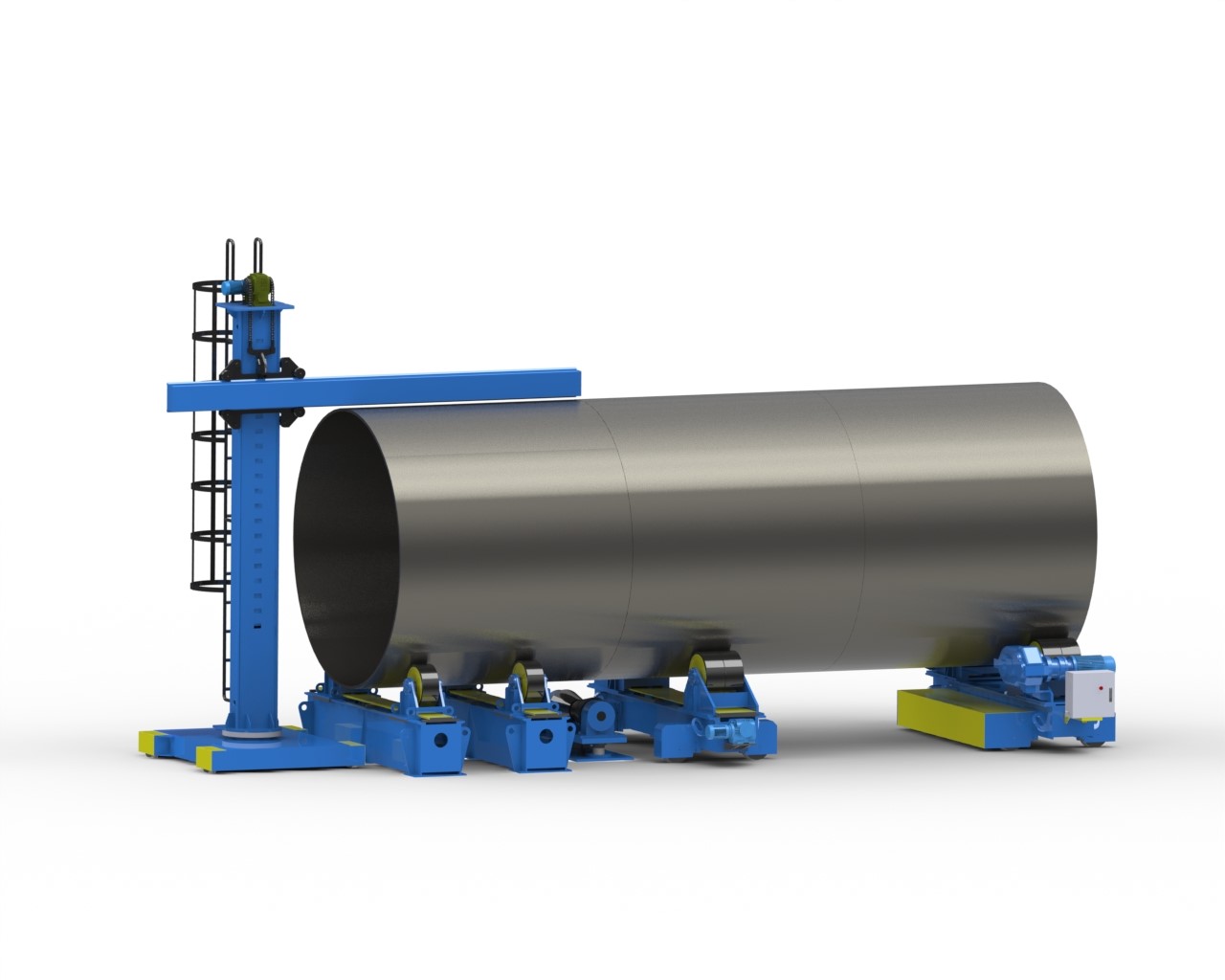

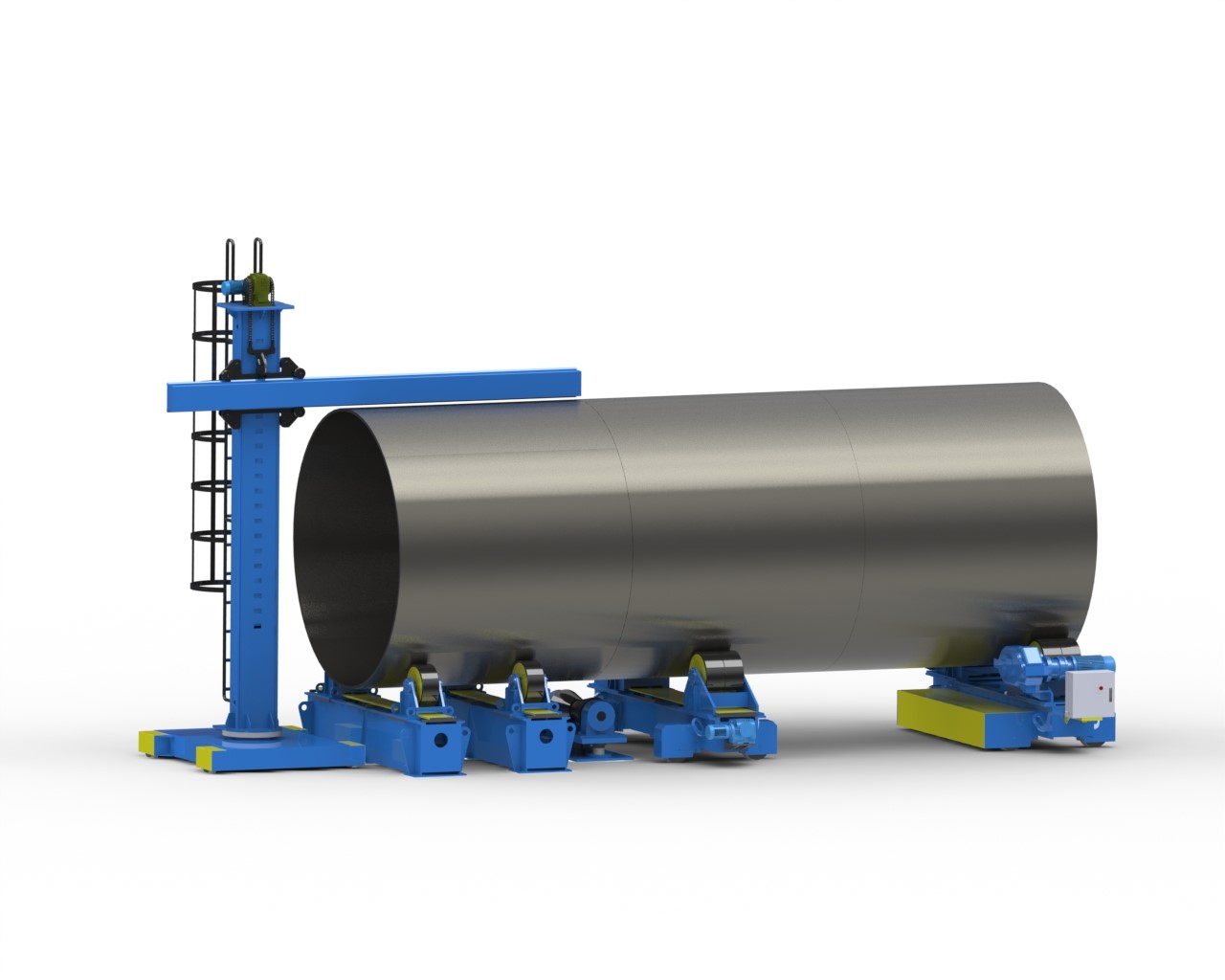

Growing Line - FITZ Series

Stable Speedy Shells Joining and Growing Process

FITZ series shell Growing Line is used for three or more pipes/ shells assembly and welding job. FITZ Growing Line is equipped with two fit-up roller beds, which have four independent hydraulic height adjustment rollers, to ensure the assembly and welding job speedy with a high performance.

Wind Tower Production LineFeatures

- Wind tower fabrication

- Pressure vessels

- Pipe assembly

Configuration detailsFITZ Growing Lineis complete with a group of 5 (five) rotators in two combinations:

Fit-up section for fit-up job consist of:

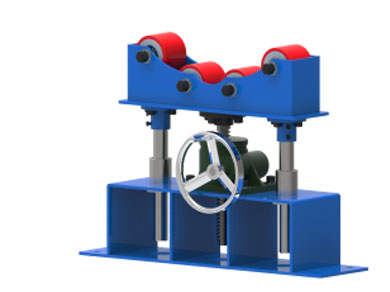

Rotator A & B:Hydraulically adjusted idle rotator which fixed on ground and has two hydraulic cylinders to adjust center distance of rollers separately.

Rotator C:supporting roll which has two “v” shaped idle rollers to allow shells to be transported longitudinally when other rollers are retracted down and Rotator c support pipes.

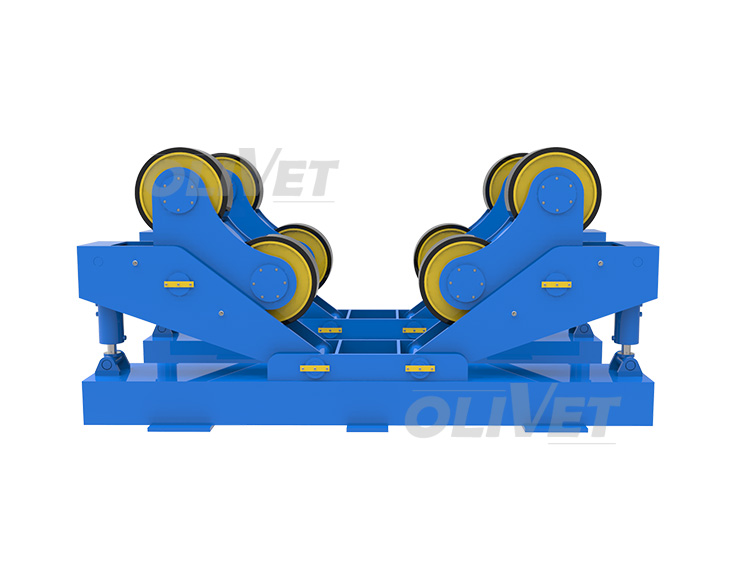

Growing section is for ‘growing job’ consist of two rotators.

Rotator D:Idler rotator- Rollers distance is adjustable by lead-screw positioning to handle different workpiece diameter and manual travel on rail.

Rotator E:Power rotator - Rollers distance is adjusted by bolts positioning and motorized travel on rail.

Scope of Delivery

1 Main control panel

2 Remote pendantgrowing line roll systemTechnical Paramter

|

Model |

FITZ-60 |

FITZ-100 |

|

Max loading capacity |

60 tons |

100 tons |

|

Rotator A & B capacity |

30 tons |

30 tons |

|

Rotator C (v-roll support) capacity |

30 tons |

50 tons |

|

Rotator D and E capacity |

60 tons |

100 tons |

|

Workpiece diameter |

Ø800-Ø4500 mm |

Ø850-Ø5500 mm |

|

Rotator A & B roller center-distance adjusting |

Hydraulic cylinder |

Hydraulic cylinder |

|

Rotartor C height adjusting |

Hydraulic cylinder |

Hydraulic cylinder |

|

Rotator D roller center-distance adjusting |

Motorized lead-screw |

Motorized lead-screw |

|

Rotator E roller center-distance adjusting |

Bolts manual |

Bolts manual |

|

Rolling speed |

100-1000mm/min (VFD) |

100-1000 mm/min (VFD) |

|

Rolling motor power |

2 X 2.2 kw |

2 X 3 kw |

|

Roller material |

Polyurethane (PU) |

Polyurethane (PU) |

|

Hydraulic control mode |

5 each separatly |

5 each separatly |

|

Rotator D horizontal moving speed |

250-2500mm/min (VFD) |

250-2500mm/min (VFD) |

|

Rails inner gauge |

2000mm |

2000mm |

Growing line working follow

lStep One:Lay dwon the two shells on Rotator A & Rotator B, Rotator D & Rotator E by crane.

lStep Two:

Join the two shells by moving Roator E on rails;

Fit-up and align seam by adjusting rollers center distance hydraulic, then spot welding;

Full circular welding

lStep Three:

Jack-up the front end of finished two shells by operating Rotator C (V-roller);

Move the finished two shells to backside by operating Rotator E;

lStep Four:

Lay down the third shell on Rotator A, B by crane;

Repeat the same work from Step one to Step three till all shells are finished.

Wuxi OLIVTE Machinery Equipment Co., Ltd., which professional in welding equipment,rotator, welding positioner, welding manipulator .

If you are interested in our products, please click here.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| HBJ-CNC Automatic Welding Positioner | HBJ-CNC Automatic Welding Positioner Olivet has a comprehensive range of positioner for automatic welding, Automatic Welding Positioner. These very... | |

| TG-600A Supporting Roller Pipe Turning Rollers Supplier fit up roller bed station | TG-600A Supporting RollerPipe Turning Rollers Supplier fit up roller bed station Specialized for pipes and cylindrical workpieces supporting Light ... | |

| FIT Fit Up Station | FIT Fit Up Station Welding Rotator FIT series Fit UP Roller Bed Stationis used for two or three pipes/ shells joining and welding job. The Fit ... | |

| FITZ Growing Line Growing Line - FITZ Series pipe and shells growing line system | FITZ Growing LineGrowing Line - FITZ Seriespipe and shells growing line system Stable Speedy Shells Joining and Growing Process FITZ series shell ... | |

| FITA Growing Line Growing Line - FITA Series | FITA Growing LineGrowing Line - FITA Series Stable Speedy Shells Joining and Growing Process FITA Series shell Growing Lineis used for three or mo... |

Похожие товары

| Portable Handheld Fiber Laser Welder – Water Cooling for Industrial Use | Продавец: Beijing JCZ Technology Co., Ltd | This portable handheld fiber laser welderis designed for industrial-grade welding operations. It ... | |

| Манометр для регулировки форсунок | Продавец: Weldy China Distributor Co.,LTD официальный дистрибьютер, официальный партнер | Артикул127.826АртикулМанометр для регулировки форсунокБрендWeldyСтрана происхожденияP.R. Китай | |

| Направляющая | Продавец: Weldy China Distributor Co.,LTD официальный дистрибьютер, официальный партнер | Артикул126.096АртикулНаправляющаяБрендWeldyСтрана происхожденияP.R. Китай | |

| Клин нагревательный, нержавеющая сталь | Продавец: Weldy China Distributor Co.,LTD официальный дистрибьютер, официальный партнер | Артикул156.668НаименованиеКлин нагревательный, нержавеющая стальНапряжение230 ВМатериал клинаНерж... | |

| Нагревательный клин, алюминий | Продавец: Weldy China Distributor Co.,LTD официальный дистрибьютер, официальный партнер | Артикул156.563НаименованиеНагревательный клин, алюминийНапряжение230 ВМатериал нагревательного кл... |