PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE

PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE

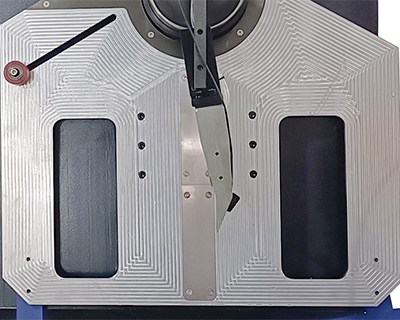

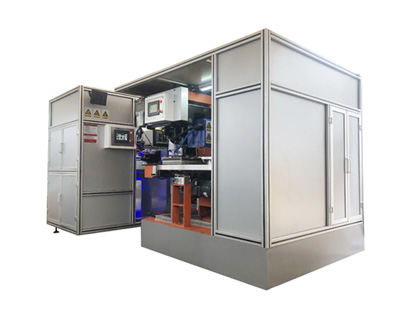

This equipment is designed for crimping and forming after welding of paper drum stainless steel rings. It is connected with our automatic laser welding equipment via a conveyor belt and then rotated and crimped at high speed. The mechanized action adopts servo digital control, which greatly shortens the product replacement time. This product must be used with our fully automatic laser welding machine to form a fully automatic production line.

THE PARAMETER OF PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE

|

Input voltage |

Enter the frequency |

Product diameter |

Product thickness |

Product width |

Dimensions |

|

3*380V |

50HZ |

120~650mm |

<0.8mm |

12~80mm |

1700*1600*1800mm |

The Application Of Paper Drum Stainless Steel Belt Industrial Crimping Machine

This equipment is a special equipment for the crimping process after the paper drum stainless steel is welded. After laser seamless welding, the hemming process is automatically carried out through the conveyor belt to reduce labor costs. The mechanical action adopts servo digital control, which greatly shortens the product replacement time. The device is beautiful in appearance design, simple in operation, easy to learn and understand.

The Advantages Of Paper Drum Stainless Steel Belt Crimping Machine

The equipment is produced by a conveyor belt combined with a laser welding machine, which changes the previous manual crimping. The equipment adopts information exchange control, which is completely unified with the previous process, and the subsequent process can be added at any time to achieve unified control. The crimping method is inverted and does not require any lubricant.

Other Notes Of Paper Drum Stainless Steel Belt Crimping Machine

1

Beautiful appearance design, simple operation, easy to learn and understand.

2

Reducing labor can save costs and reduce scrap rate.

3

The mechanical action adopts servo digital control to shorten the adjustment time.

4

The way of crimping is upside down, no need to add any lubricant.

5

It can be used together with the laser welding equipment produced by our company to realize a fully automatic production line.

6

Adopt information exchange control to achieve unified control with the previous process.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| MESH BASKET STAINLESS STEEL BELT AUTOMATIC PRODUCTION LINE | The equipment adopts advanced laser continuous welding technology, through the welding machine fixture feeding - cutting - welding, mechanical arm ... | |

| LASER SEAM WELDING | LASER SEAM WELDING Laser seam weldingis a superior welding technique that provides precise and efficient joining of two metal sheets without the n... | |

| STAINLESS STEEL BELT STRETCHING MACHINE | The equipment is used to stretch the workpiece after the welding and crimping process. After the completion of our welding and crimping process, th... | |

| STAINLESS STEEL BELT CHAMFERING MACHINE | The chamfering process of the stainless steel strip of the glass pot cover after stretching and pressing is an indispensable process in the automat... | |

| MEDIUM FREQUENCY WELDER | The single-rib brake shoe seam frequency welding machineadopts intermediate frequency welding technology. The intermediate frequency transformer ha... |