EN 13889 Shackle

EN 13889 shacklespecifies the design, materials, testing, and marking requirements for shackles used in lifting applications. It requires that the shackles be manufactured from high-quality materials and meet certain strength and durability criteria. The standard also specifies testing procedures to ensure that the shackles can withstand the loads and forces they are designed to carry.

When selecting an BS EN 13889shackle, it is important to choose the right size and working load limit for the specific task at hand to ensure safe and effective use. It is also important to ensure that the shackle is marked with the appropriate information, including the working load limit, the manufacturer's name or trademark, and the EN 13889 standard designation.

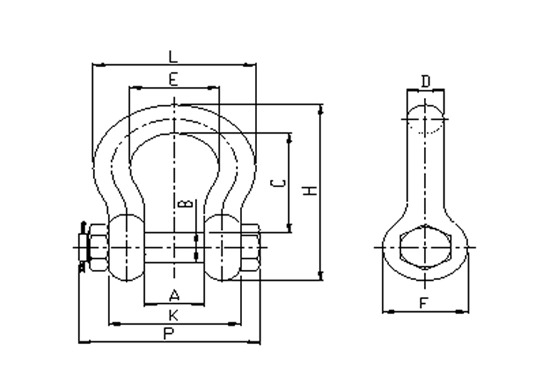

Specifications of EN 13889 Shackle

|

Size |

WLL |

Weight |

Dimensions |

Tolerance |

||||||||||

|

(T) |

(Kg) |

A |

B |

C |

D |

E |

F |

H |

K |

L |

P |

|||

|

3/16" |

36 |

±5% |

||||||||||||

|

1/4" |

8 |

42 |

±5% |

|||||||||||

|

5/16" |

31 |

19 |

53 |

49 |

±5% |

|||||||||

|

3/8" |

1 |

63 |

36 |

±5% |

||||||||||

|

7/16" |

19 |

43 |

27 |

65 |

±5% |

|||||||||

|

1/2" |

2 |

16 |

47 |

33 |

30 |

46 |

±5% |

|||||||

|

5/8" |

27 |

19 |

60 |

16 |

42 |

39 |

106 |

59 |

74 |

97 |

±5% |

|||

|

3/4" |

71 |

19 |

51 |

47 |

125 |

89 |

109 |

±5% |

||||||

|

7/8" |

84 |

22 |

58 |

54 |

147 |

102 |

123 |

±5% |

||||||

|

1" |

43 |

96 |

25 |

68 |

60 |

166 |

93 |

118 |

139 |

±5% |

||||

|

1 1/8" |

46 |

107 |

74 |

103 |

130 |

149 |

±5% |

|||||||

|

1 1/4" |

12 |

119 |

32 |

82 |

76 |

208 |

146 |

171 |

±5% |

|||||

|

1 3/8" |

57 |

38 |

131 |

35 |

89 |

84 |

228 |

127 |

159 |

186 |

±5% |

|||

|

1 1/2" |

17 |

148 |

38 |

98 |

92 |

254 |

174 |

194 |

±5% |

|||||

|

1 3/4" |

25 |

73 |

177 |

45 |

127 |

109 |

303 |

163 |

217 |

328 |

±5% |

|||

|

2" |

35 |

197 |

51 |

146 |

127 |

341 |

248 |

260 |

±5% |

|||||

|

2 1/4" |

95 |

63 |

221 |

57 |

160 |

143 |

283 |

209 |

274 |

302 |

±5% |

|||

|

2 1/2" |

55 |

105 |

264 |

184 |

150 |

455 |

235 |

321 |

328 |

±5% |

||||

|

3" |

85 |

67 |

127 |

85 |

328 |

76 |

200 |

165 |

546 |

279 |

371 |

378 |

±5% |

|

|

3 1/2" |

120 |

113 |

133 |

95 |

371 |

92 |

229 |

203 |

632 |

323 |

432 |

425 |

±5% |

|

|

4" |

150 |

141 |

140 |

107 |

368 |

104 |

254 |

228 |

340 |

457 |

452 |

±5% |

||

|

Production Standard |

Meet EN13889 and US Federal Specification RR-C-271F, Type IVA, Grade B |

|||||||||||||

|

Production Process |

Drop Forging |

|||||||||||||

|

Material Grade |

Carbon Steel for Shackle Body and Alloy Steel For Shackle Pin |

|||||||||||||

|

Heat Treatment |

Quenching and Tempering |

|||||||||||||

|

Safety Factor |

6:01 |

|||||||||||||

|

Finish |

Hot Dip Galv. |

|||||||||||||

|

Temperature Range |

-20℃up to +200℃/td> |

|||||||||||||

|

Fatigue properties |

Under 1.5 Times of working load limit,the Fatigue test could reach over 20000 Cycles. |

|||||||||||||

|

Low temperature Impact Test |

Charpy V-notch testing -20℃?with Min. 27J |

|||||||||||||

|

Supply Certificate |

Mill Test Certificate According to EN 10204 3.1; Under request, CCS/ABS/DNV third party |

|||||||||||||

|

Inspection certificate can be supplied, but the cost would be extra to buyer account. |

||||||||||||||

If you are looking for a reliable rigging supply company, please contact us, and we will be your best to meet all the needs of customers.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Marine D Ring | Marine d ring redare a versatile and essential piece of hardware for securing and attaching equipment on marine vessels, and are designed to provid... | |

| Disc Harrow Blade | Zhonghe also provides sharpening disc harrow blades, among other agricultural machinery and equipment. Our disc harrow blades are designed to be du... | |

| G80 Connecting Link | The g80 chain connectoris part of a wider range of lifting and rigging components that conform to the European Standard EN 818-4, which specifies r... | |

| G80 Clevis Self Locking Hook | The G80 clevis self locking safety hookis often used in applications such as rigging, hoisting, and towing, where a secure and reliable connection ... | |

| EN 13889 Shackle | EN 13889 shacklespecifies the design, materials, testing, and marking requirements for shackles used in lifting applications. It requires that the ... |

Похожие товары

| China manufacturer bolts heater 1.2311(4)-φ15X500 for power generation | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China manufacturer bolts heater 1.2311(4)-φ15X500 for power generationIs YOYIK for the use o... | |

| Индивидуальная форма двигателя | Продавец: 846123 | 90 Трехрядная высокоскоростная прогрессивная штамповочная формаИндивидуальная моторная пресс-форм... | |

| Emergency Snow Chains | Продавец: Zhejiang Pujiang Bohu Chain Stock Co., Ltd. | Our Emergency Snow Chains are engineered to deliver unbeatable grip on snow and ice, ensuring t... | |

| Brass Brake Lining Rivets | Продавец: Taizhou First Rivet Co.,Ltd | Our Brass Brake Lining Rivets are precision-engineered to provide a strong and reli... | |

| China made SEAL,STEAM,LP-B6TH DIPRAGM Steam Turbine CIV CB25-8.82/0.98/0.118 for power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made SEAL,STEAM,LP-B6TH DIPRAGM Steam Turbine CIV CB25-8.82/0.98/0.118 for power plantis a... |