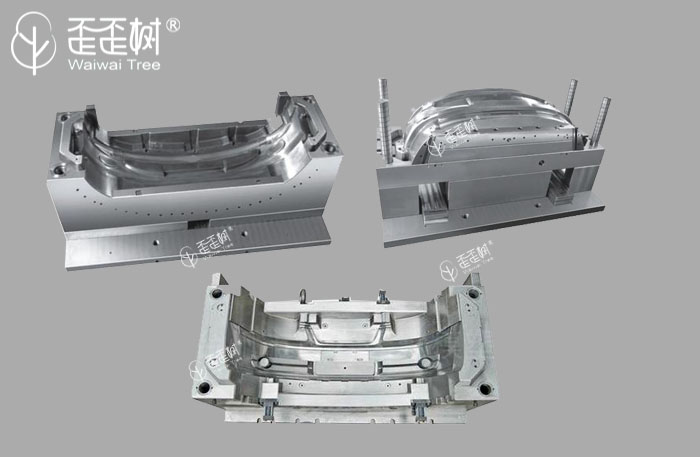

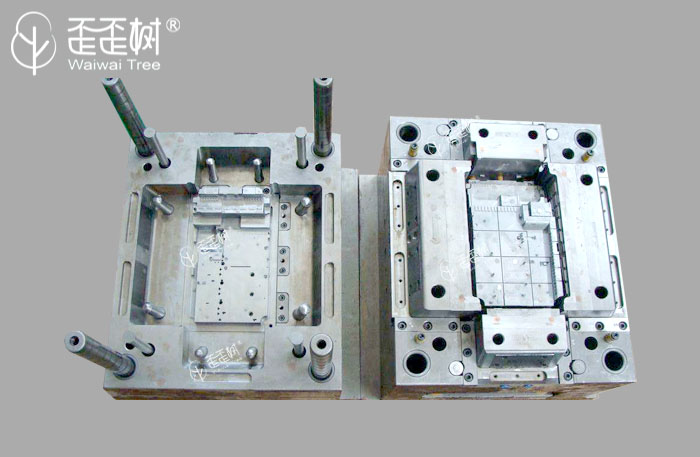

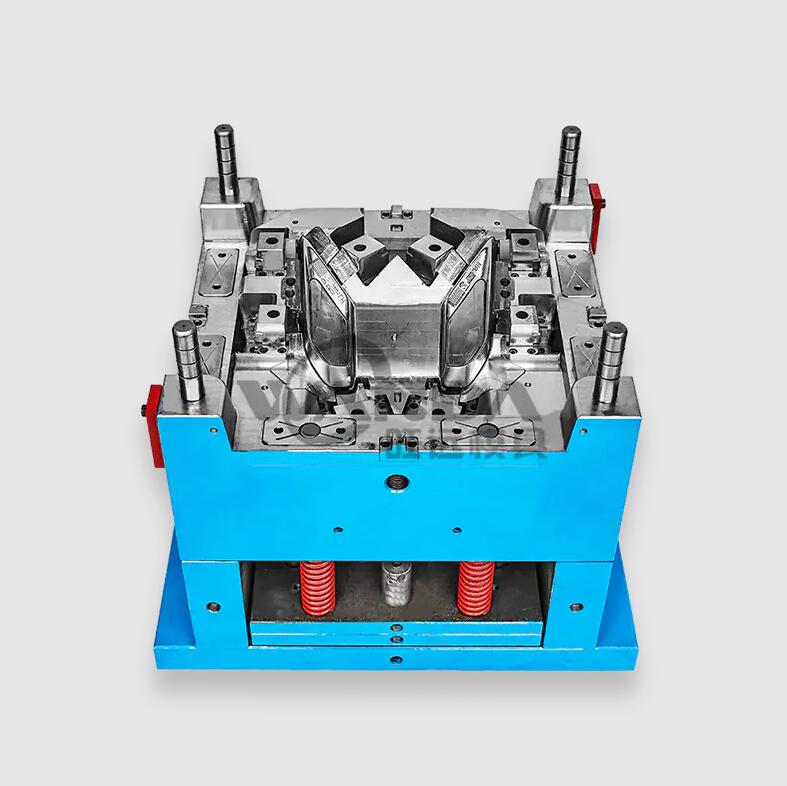

Auto Parts Mould

Auto Parts Mould Features

Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the cavity pressure should be as small as possible, the exhaust should be smooth, the discharge position, shape, and material flow direction should be fully considered, especially some small ribs. To do the active exhaust, there must be a overflow trough. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed. It solves the problems of lightweight, leakage safety and aging of bmc car parts, reduces costs and improves product quality.

auto parts moldmainly include car bumper molds, battery box molds, lamp molds, seat molds, engine intake pipe molds, electric control box molds and so on.

SMC/ BMCCompositeProducts Description:

SMC, BMC thermosetting plastic products are produced by SMC and BMC plastic molding process. What is smc plastic?SMC/BMC is one of thermosetting plastics, and SMC/BMC thermosetting plastics are thermosetting molding compounds made of unsaturated polyester resin as matrix resin. The main components of SMC/BMC thermosetting plastics include resins, thickeners, low shrinkage additives, fillers, internal mold release agents, colorants, stabilizers, and the like. It is first formulated into a resin paste and then used to impregnate or blend with a reinforcing material to form a preformed molding material. According to the preforming process and the shape of the obtained preformed material, it can be divided into SMC thermosetting plastic and BMC thermosetting plastic or DMC integral molding plastic. SMC/BMC thermosetting plastics are easy to form, have low molding shrinkage, high dimensional accuracy and good processing performance.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BMC, SMC, GRP, GFK Wall Panel | Aobang composite Wall Panel is divided into: BMC Wall seat, SMC Wall Panel, GRP Wall Panel, GFK Wall Panel. Composite Wall Panel the main function... | |

| Frame Moulding | Frame Moulding Features Frame Moulding includes BMC Frame Moulding and SMC Frame Moulding which is mainly for pressure molding, the cavity pressur... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... | |

| BMC/SMC Molded Products | SMC, BMC thermosetting plastic products are produced by SMC and plastic smcmolding process. Types of BMC/SMC Molded Products BMC SMCMotor SM... |

Похожие товары

| Precision And Durable Multi-Specification Automobile Buckle Mold | Продавец: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| Индивидуальная форма двигателя | Продавец: 846123 | 90 Трехрядная высокоскоростная прогрессивная штамповочная формаИндивидуальная моторная пресс-форм... | |

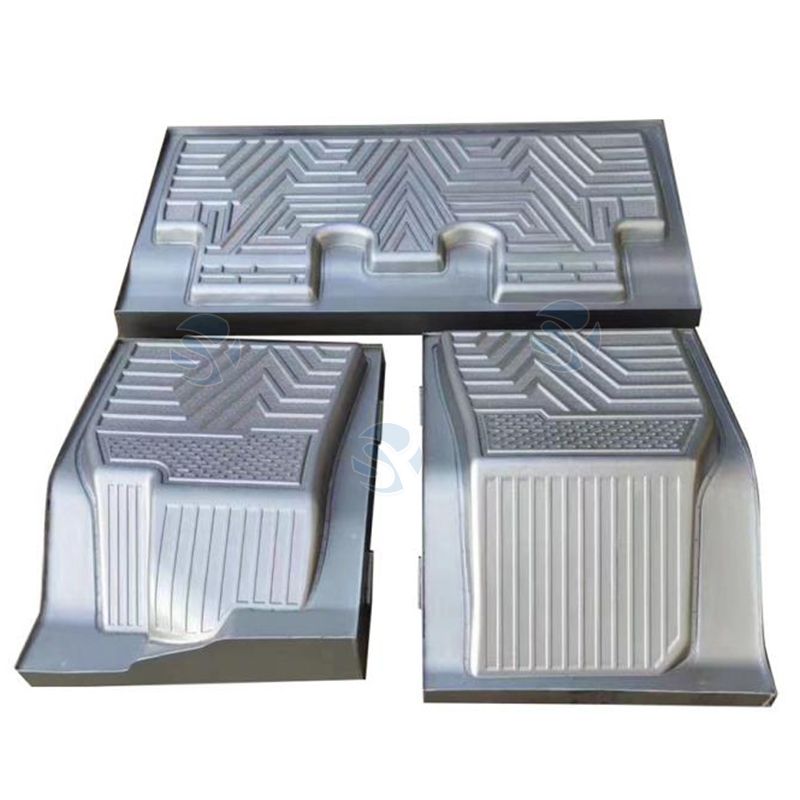

| Car Mat Aluminium Vacuum Mould | Продавец: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | Продавец: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | Продавец: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |