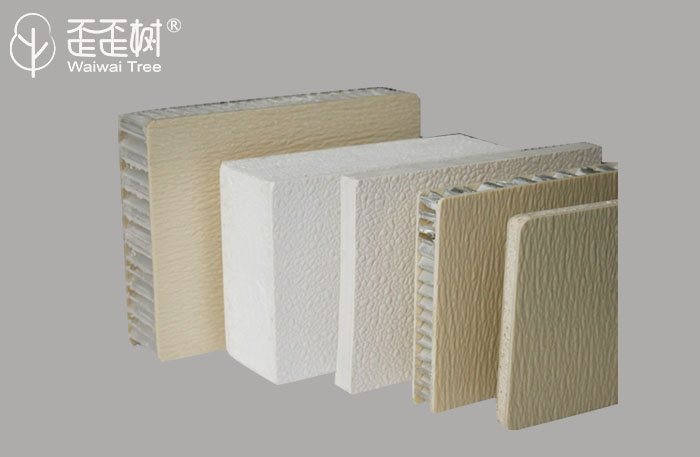

BMC, SMC, GRP, GFK Wall Panel

Aobang compositeWall Panelis divided into: BMC Wall Panel, SMC Panel, grpWall Panel, GFK Wall Panel.

Composite Wall Panel the main functions: use imported silver ion, special effect antibacterial; energy saving; anti-corrosion, waterproof and moisture proof, mildewproof, fireproof; no harmful substances, no formaldehyde; easy to clean and maintain; scratch resistant; can be repeatedly disassembled, easy to repair; low carbon Environmental protection, surface diffuse reflection and energy saving; can be recycled, the economical applicability of building materials, high cost performance; beautiful appearance.

Established in 2010 and located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province, Zhejiang Aobang Technology Co., Ltd. has extensive bulk molding compound processand many refined testing laboratories as a spinal column in the industry. Whether at home or abroad, Zhejiang Aobang Technology Co., Ltd. can manufacture top quality bmc compoundmolds with advanced mold making concept, proprietary application technology and production technology. By the way, being a high-tech enterprise, it is a fact that this company enjoys a good fame in the new motor and energy automobile industry in Hangzhou.

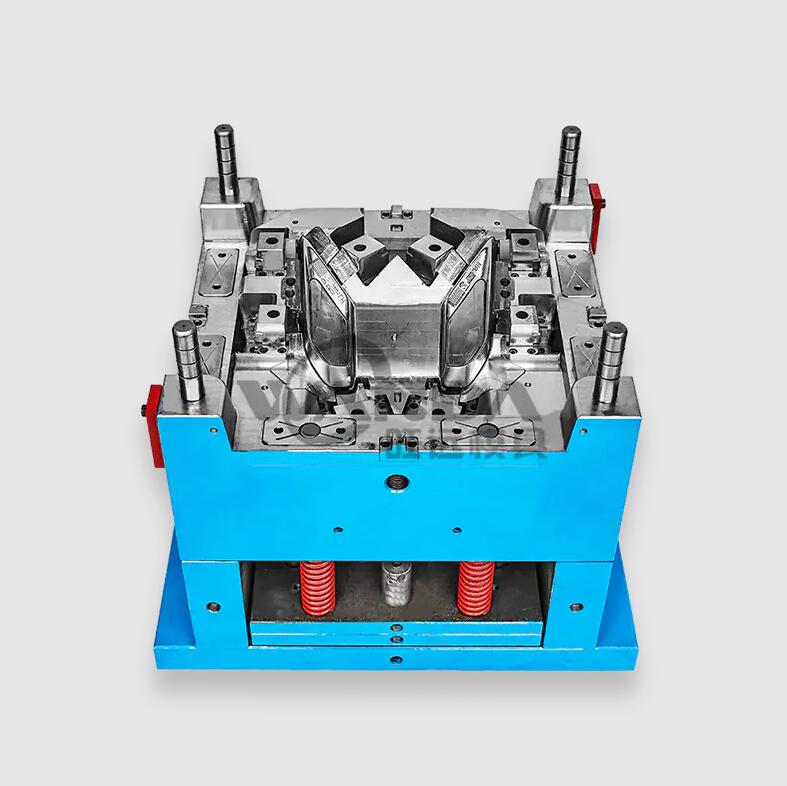

SMC and BMC compositerequire heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

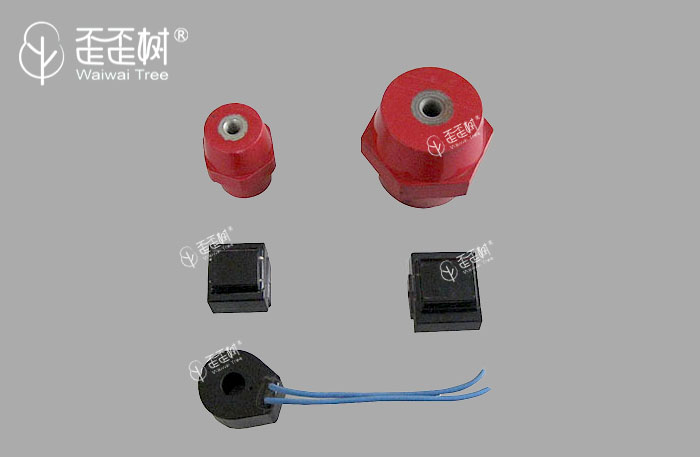

| BMC/SMC Insulation | SMC/BMC Insulation High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulated. ... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safet... | |

| BMC, SMC, GRP, GFK Ceiling | Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, . The ceiling materials have been developed for more than ten yea... | |

| BMC/SMC Insulation | BMCInsulationand SMC Insulation High-strength, wear-resistant, fire-resistant, color BMCcompositematerial for medium and low voltage insulators su... | |

| BMC/SMC Motor | BMC/SMC Electric MotorsDescription Motor BMCreplaces traditional iron and aluminum, reduces the process, seals more, and has higher safety facto... |

Похожие товары

| Precision And Durable Multi-Specification Automobile Buckle Mold | Продавец: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| Индивидуальная форма двигателя | Продавец: 846123 | 90 Трехрядная высокоскоростная прогрессивная штамповочная формаИндивидуальная моторная пресс-форм... | |

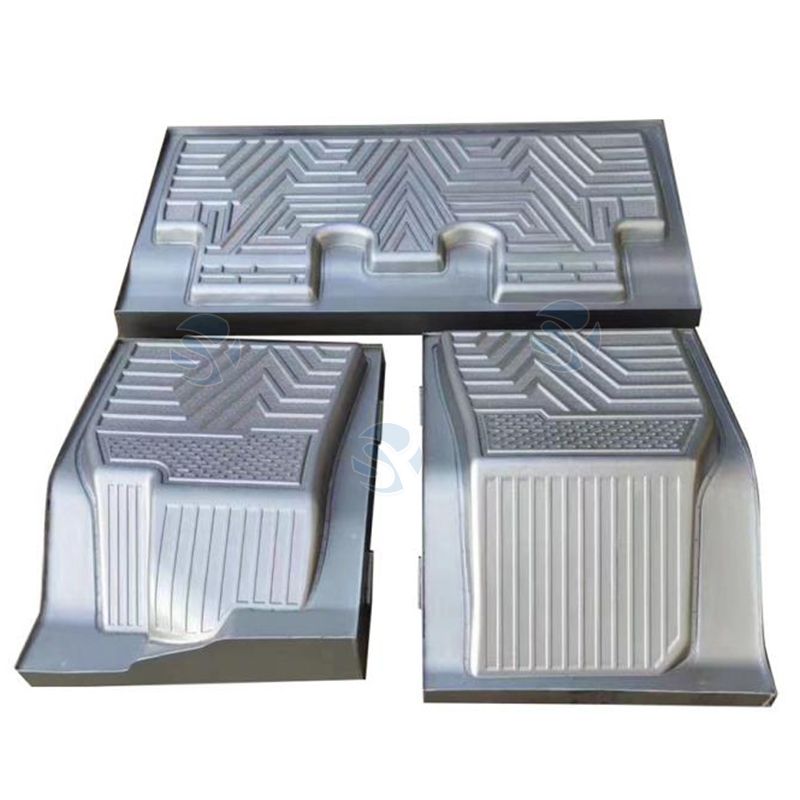

| Car Mat Aluminium Vacuum Mould | Продавец: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | Продавец: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | Продавец: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |