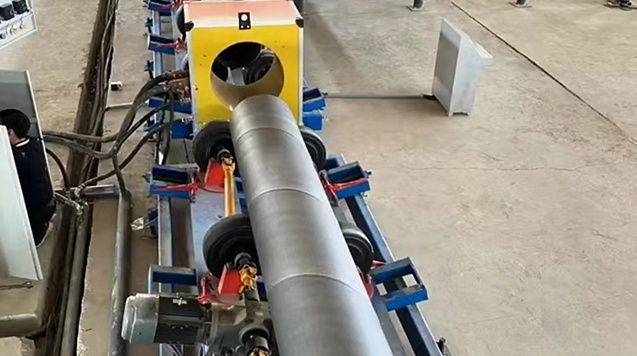

ULTRASONIC STEEL PIPE TESTING EQUIPMENT

Все товары поставщика

Ultrasonic pipe testingwith ultrasonic pipe inspection equipmentrefers to a non-destructive testing method that uses ultrasound to inspect internal defects in metal components. Using an acoustic transducer to emit ultrasonic waves through a coupling agent to the surface of the component, the ultrasonic waves will have different reflected signals (echoes) when encountering different interfaces when propagating inside the component. By utilizing the time difference between different reflected signals transmitted to the probe, defects inside the component can be detected. The size, location, and approximate nature of defects can be determined based on the height and position of the echo signal displayed on the fluorescent screen. Ultrasonic pipe testing is more sensitive to cracks, incomplete penetration, and incomplete fusion defects, but less sensitive to pores and slag inclusions. Ultrasonic testing has poor visualization and is not sensitive to near surface defects (known as blind spots in ultrasound).

Steel pipe weld flaw detection is divided into online flaw detection mode and offline flaw detection mode, and the ultrasonic pipe testing equipmentadopts beam type water film flaw detection. The ultrasonic pipe testing system adopts the combination of computer control and real-time signal acquisition and processing technology, and uses multi-channel digital flaw detector with the support of high-speed computer to realize automatic detection of defects, automatic evaluation of defects, display and record (defect) echo amplitude, storage and printing detection data.

COMPOSITION OF ULTRASONIC FLAW DETECTION EQUIPMENT

- Water circulation system.

ULTRASONIC PIPE INSPECTIONEQUIPMENT SYSTEM DETAILS

This system is an online ultrasonic automatic detection device for steel pipe welds and pipe bodies. It uses ultrasonic-beam water film method for flaw detection. According to customer requirements, it is designed and customized under the premise of meeting stability and efficiency. The system adopts computer control and signal real-time acquisition and processing technology, and uses multi-channel digital flaw detector with the support of high-speed computer to realize automatic detection of defects, automatic evaluation of defects, display and record (defect) echo amplitude, storage and printing detection Data, automatically generate test reports in the format required by the user.

The steel pipe machinealso has many advantages such as advanced instruments, high degree of automation, fast detection speed, strong anti-interference ability, and accurate judgment. The overall technology is at the domestic leading level.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| High Frenquency Welded Steel Pipe Production Line | A high frequency pipe welding machineis a system used for manufacturing steel pipes with high-frequency welding technology. The welded pipe product... | |

| ANTI-CORROSION AND INSULATED STEEL PIPE PRODUCTION LINE | An anti-corrosion and insulated internal pipe coating equipmentproduction line is a specialized system used for manufacturing steel pipes that are ... | |

| TIANXIANGHAO STEEL PIPE MACHINE | Stainless steel pipe threading machineis a manufacturing system that is used to produce different types of steel pipes, such as spiral welded pipes... | |

| INDUSTRIAL X RAY EQUIPMENT FOR STEEL PIPE INSPECTION | The pipe x ray equipmentfor spiral steel pipes is suitable for non-destructive testing of the quality of spiral steel pipe welds. The X ray radiogr... | |

| STEEL PIPE DELIVERY MACHINE | A pipe handling systemis a specialized device used to transport steel pipes from one location to another effectively and safely. It is designed to ... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |