ULTRASONIC STEEL PIPE TESTING EQUIPMENT

Ultrasonic pipe testingwith ultrasonic pipe inspection equipmentrefers to a non-destructive testing method that uses ultrasound to inspect internal defects in metal components. Using an acoustic transducer to emit ultrasonic waves through a coupling agent to the surface of the component, the ultrasonic waves will have different reflected signals (echoes) when encountering different interfaces when propagating inside the component. By utilizing the time difference between different reflected signals transmitted to the probe, defects inside the component can be detected. The size, location, and approximate nature of defects can be determined based on the height and position of the echo signal displayed on the fluorescent screen. Ultrasonic pipe testing is more sensitive to cracks, incomplete penetration, and incomplete fusion defects, but less sensitive to pores and slag inclusions. Ultrasonic testing has poor visualization and is not sensitive to near surface defects (known as blind spots in ultrasound).

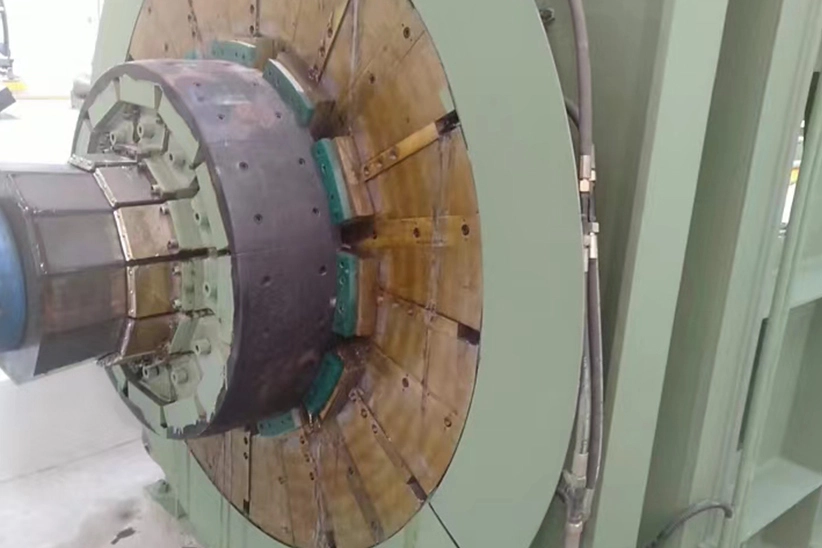

Steel pipe weld flaw detection is divided into online flaw detection mode and offline flaw detection mode, and the ultrasonic pipe testing equipmentadopts beam type water film flaw detection. The ultrasonic pipe testing system adopts the combination of computer control and real-time signal acquisition and processing technology, and uses multi-channel digital flaw detector with the support of high-speed computer to realize automatic detection of defects, automatic evaluation of defects, display and record (defect) echo amplitude, storage and printing detection data.

COMPOSITION OF ULTRASONIC FLAW DETECTION EQUIPMENT

- Water circulation system.

ULTRASONIC PIPE INSPECTIONEQUIPMENT SYSTEM DETAILS

This system is an online ultrasonic automatic detection device for steel pipe welds and pipe bodies. It uses ultrasonic-beam water film method for flaw detection. According to customer requirements, it is designed and customized under the premise of meeting stability and efficiency. The system adopts computer control and signal real-time acquisition and processing technology, and uses multi-channel digital flaw detector with the support of high-speed computer to realize automatic detection of defects, automatic evaluation of defects, display and record (defect) echo amplitude, storage and printing detection Data, automatically generate test reports in the format required by the user.

The steel pipe machinealso has many advantages such as advanced instruments, high degree of automation, fast detection speed, strong anti-interference ability, and accurate judgment. The overall technology is at the domestic leading level.

Send product request

Other supplier products

| Anti-corrosion and Insulated Steel Pipe Production Line | An anti-corrosion and insulatedinternal pipe coating equipment, internal pipe coating machineproduction line is a specialized system used for manuf... | |

| STEEL PIPE END EXPANDING MACHINE | Pipe expander machineis a professional equipment for expanding and rounding the end of spiral submerged arc welded steel pipe, mainly used in oil a... | |

| STEEL PIPE CONVEYOR | This pipe handling conveyor systemsis a conveying equipment used in the production and testing process of steel pipes, achieving fast transportatio... | |

| High Frenquency Welded Steel Pipe Production Line | A high frequency pipe welding machineis a system used for manufacturing steel pipes with high-frequency welding technology. The welded pipe product... | |

| TIANXIANGHAO STEEL PIPE MACHINE | Stainless steel pipe threading machineis a manufacturing system that is used to produce different types of steel pipes, such as spiral welded pipes... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |