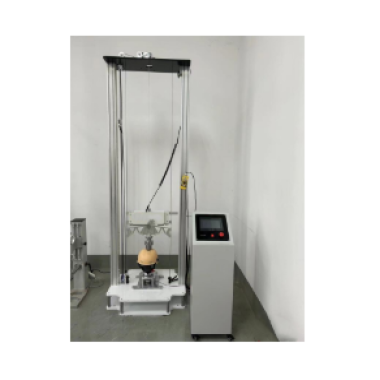

Safety Helmets Impact and Penetration Resistance Tester

The Safety Helmets Impact and Penetration Resistance Tester is a dual-function testing system designed to evaluate helmet safety under both impact and penetration conditions. It ensures compliance with national and international standards, supporting quality control, certification testing, and research applications.

Application

(1) Impact resistance testing for industrial helmets (e.g., construction safety helmets, GB/T 2812 certified)

(2) Impact testing for cycling helmets (road, mountain, BMX)

(3) Impact testing for motorcycle helmets (full-face, modular, open-face)

(4) Penetration resistance testing for climbing helmets and rope-access helmets

(5) Custom helmet testing for sports or military applications

(6) R&D and batch quality control for OEM helmet lines (including EN 960 S/M/L headforms)

(7) Certification testing for GB/T 2811-2019, ISO 6220-2, and CE/EN compliant helmets

Standards

(1) GB/T 2811-2019 – Helmet safety and impact resistance

(2) GB/T 2812-2006 – Testing methods for impact absorption and penetration resistance

(3) ISO 6220-2 – Road vehicles restraint systems energy absorption test methods

(4) EN 960 – Headforms for protective helmet testing

(5) CE Certification (Conformité Européenne)

Features

(1) Dual-Function Versatility: Rapid fixture exchange allows switching between impact and penetration tests in under 10 minutes

(2) Ultra-Precision Impact Analysis: 5 kg hemispherical hammer with 1,000 mm drop height and 20,000 N force sensor at 0.1 N resolution

(3) Penetration Resistance Validation: 3 kg conical tip hammer (60° ±0.5°, 40 mm min., 45–50 HRC) simulating sharp object impacts

(4) Smart Data Acquisition: Real-time force curves with pass/fail alerts and 1 ms resolution

(5) Industrial Durability: 4 m steel frame with anti-vibration design, IP65-rated control panel

(6) Safety Systems: Light curtain, energy-absorbing base, and emergency stop

(7) Universal Compatibility: EN 960 headforms (S/M/L) and custom 3D-printed headforms for specialized helmets

Parameters

| Specification | Impact Test | Penetration Test |

|---|---|---|

| Drop Height | 1,000 ±5 mm | 1,000 ±5 mm |

| Hammer Weight | 5.0 ±0.1 kg | 3.0 ±0.05 kg |

| Tip Geometry | Hemisphere (R50 ±1 mm) | Cone (60° ±0.5°, 40 mm min.) |

| Force Sensor | 20,000 N, 5 kHz sampling | N/A (mechanical stop) |

| Data Resolution | 0.1 N | 0.1 mm displacement |

| Frame Height | 4,000 mm | 4,000 mm |

| Power Requirements | 220V/110V AC, 50/60Hz, 800 W | 220V/110V AC, 50/60Hz, 800 W |

Accessories

(1) Headform Kit: EN 960 S/M/L sizes with polyurethane skin coating

(2) Hammer Set: Impact (5 kg) and penetration (3 kg) hammers with storage case

(3) Calibration Tools: NIST-traceable force gauge and Rockwell hardness tester

(4) Safety Kit: Light curtain, energy-absorbing base mat, emergency stop button

(5) Software License: HelmetImpact Pro, cloud-connected with API integration for QMS systems

(6) Installation & Training: On-site setup by certified engineers, 16-hour virtual operator training

Test Procedures

(1) Install the helmet on the selected headform.

(2) Select impact or penetration test mode and attach the corresponding hammer.

(3) Set drop height, test parameters, and safety interlocks via the HMI.

(4) Conduct the test; monitor real-time force/displacement curves.

(5) Record peak forces and penetration measurements; evaluate against standard requirements.

(6) Generate automated pass/fail reports and export data for QC or certification.

Maintenance Information

(1) Inspect hammers, headforms, and force sensors regularly for wear or damage.

(2) Clean frame, rails, and fixtures with non-corrosive solution.

(3) Verify calibration of force sensors and drop heights periodically.

(4) Lubricate linear bearings and moving components as per schedule.

(5) Store in a clean, dry environment to maintain precision and service life.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Multi-Finger Scratch/Mar Tester | Standards Chrysler LP-463DD-18-01 Scratch and Mar Resistance of Automotive Plastics Chrysler PF-10938 Scratch and Mar - Resistance of Molded-In-C... | |

| Battery Electrode Resistance Tester | Standard ASTM B193: Standard Test Method for Resistivity of Electrical Conductor Materials ISO 18516: Conductive Coatings – Measurement of ... | |

| Safety Helmets Wearing Stability Tester | Standard GB 811-2022: Safety Helmets – General Technical Requirements GB 24429-2009: Sports Helmets – Requirements and Test Methods ... | |

| Protective Clothing Synthetic Blood Penetration Tester | Introduction It is applicable to the resistance of the protective clothing to the synthetic blood penetration under different levels of test press... | |

| Face Mask Tensile Tester | Introduction: The test machine uses the integrated structure of the motor and the speed control system to drive the synchronous belt deceleration ... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |