Battery Isothermal Calorimeter

Battery Isothermal Calorimeter is a professional instrument developed based on the principle of power compensation isothermal calorimetry for testing the thermal characteristics of various types of lithium batteries, capable of realizing the measurement of the thermal characteristics of lithium batteries' charging and discharging as well as the thermal and physical parameters, providing accurate, stable and reliable basic thermal data for the thermal simulation of batteries, the optimization of the design of the thermal management system, as well as the assessment of the thermal safety performance of batteries.

Application

Isothermal calorimeters are widely used in important industries and fields such as new energy vehicles, energy storage, consumer electronics, and aerospace. These instruments can measure the heat generation characteristics and thermophysical parameters of lithium-ion batteries during charging and discharging, providing accurate, stable, and reliable fundamental thermal data for battery thermal simulation, thermal management system design optimization, and battery thermal safety performance evaluation.

Features

1. In an isothermal environment, it is compatible with the power compensation method and the heat - flow method to measure the heat generated during battery charging and discharging. This not only ensures the accuracy of thermal characteristic measurement for relatively large - sized batteries but also improves the sensitivity of heat measurement for relatively small - sized batteries.

2. It has an instrument calibration mode, which can calibrate the measurement accuracy of charging and discharging thermal behavior parameters under different conditions.

3. It is equipped with a heat capacity measurement mode. By using the comparative method to measure heat capacity, it reduces the operational requirements for heat capacity testing and can accurately measure the heat capacity of batteries at different temperatures.

4. The integrated battery charging and discharging module enables the switching of charging and discharging modes, the setting of constant - current/constant - voltage charging modes, the setting of charging/discharging currents, and the real - time calculation of battery power.

5. Network communication is adopted to achieve remote operation of the instrument and remote data transmission, ensuring the safety of testers.

6. It can simultaneously record voltage, current, and temperature data during the battery charging and discharging process.

7. An optional nitrogen purging module can be selected to ensure the accuracy of low - temperature measurement and effectively suppress the problem of low - temperature condensation.

Parameters

|

Calorimeter Body |

(5~40)°C, <85%RH |

|

Operating Environment |

(-40~100)ºC |

|

Oil Bath Temperature Control Range |

Isothermal Power Compensation Mode, Isothermal Heat Flow Mode, Specific Heat Capacitance Mode |

|

Experimental Modes |

±0.005°C |

|

Temperature Stability |

0.001°C |

|

Temperature Resolution |

L345mm×W230mm×H100mm |

|

Maximum Cell Size |

200W |

|

Maximum Compensated Power |

10mW (power compensation mode); 0.2mW (heat flow mode) |

|

Calorimetric Sensitivity |

±1% (power compensation mode); ±2% (heat flow mode) |

|

Absorption and Expiration Enthalpy Measurement Accuracy |

10mW (Power Compensation Mode); 0.2mW (Heat Flow Mode) |

|

Baseline Noise |

Standard with 2 channels |

|

Heating Channels |

Standard with 8 channels |

|

Temperature Measurement Channels |

RJ45 |

|

Instrument Interfaces |

(5~25)L/min |

|

Adjustable Gas Flow Rate |

AC220V/50Hz |

|

Power Supplied Power Supply |

600W |

|

Maximum Power |

(-55~200 )°C |

|

Oil Bath |

±0.01°C |

|

Setting Temperature Range |

0.01°C |

|

Temperature Stability |

3kW |

|

Display Resolution |

1.5kW@20°C, 1.5kW@0°C, 1kW@-20°C, 0.3kW @-40°C |

|

Heating Power |

12×11/16cm |

|

Refrigeration Power |

5L |

|

Bath Openings/Size |

Serial port |

|

Charging |

(5~40)°C, <85%RH |

|

Calorimeter Body |

(-40~100)ºC |

Accessoriess

Core measurement components

Temperature control and power compensation components

Heat exchange and heat dissipation components

Battery fixing and electrical connection components, etc.

Test Procedures

Check that the power supply and gas supply of the equipment are properly connected.

Prepare pure water or distilled water for filling the calorimeter, ensuring the water quality is pure to avoid affecting the experimental results.

Prepare battery samples according to the experimental requirements, ensuring that the quantity and quality of the samples meet the experimental standards.

Turn on the power switches of the calorimeter main unit, printer, electronic balance, computer, and other equipment in sequence.

Wait for the instrument to preheat to a stable state; the preheating time is usually determined by the instrument's instruction manual.

According to the calorimeter instruction manual, add an appropriate amount of pure water or distilled water to the inner cylinder of the instrument.

Observe the water level indicator to ensure the water level reaches the specified position.

Install the battery sample in the specified position of the calorimeter, ensuring good contact between the sample and the instrument.

Install ignition wires, ignition electrodes, and other accessories as needed, ensuring they are in full contact with the sample.

Enter relevant parameters on the test interface, such as sample number, mass, and mass of combustion aid.

Set the test conditions according to the experimental requirements, such as temperature and time.

Click the "Start Experiment" button to start the test program.

During the test, observe the status information on the instrument display screen to ensure the test proceeds smoothly.

After the test is completed, the instrument will automatically print out the test results.

Perform data processing and analysis of the test results as needed.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Liquid Sustained Combustion Tester | This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 32.5.2 Test L.2: Sustained Combusti... | |

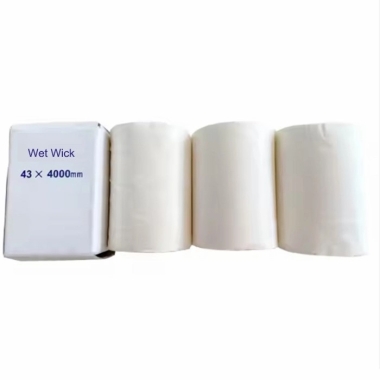

| Wet Wick for Humidity Test Chamber | Hanging method The first step is to cut a suitable wet bulb gauze for thehumidity test chamber. The second step is to hang the wet bulb gauze on ... | |

| aatcc scorch & sublimation tester丨aatcc scorch & sublimation chamber | Brief Introduction Scorch/Sublimation Tester is used in the laboratory to evaluate colour fastness to dry heat, hot pressing, and sublimation, as ... | |

| Catheter Leakage and Compliance Tester | The Catheter Leakage and Compliance Tester is a professional testing device used to evaluate the expansion capacity (compliance) and leak resistanc... | |

| Goggles Puncture Resistance Testing Machine | Applicable standards: GB 811-2010 ECE R22.05 EN1077 Purpose It is to make a certain weight of sharp objects fall from the height specified i... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |