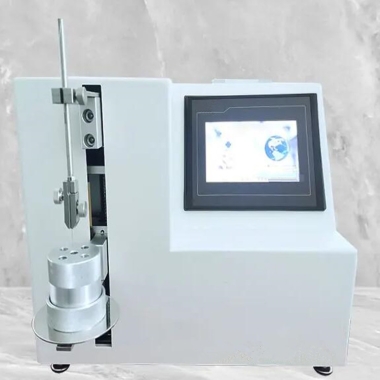

Minimum Ignition Energy (MIE) – Dust Cloud Tester

Dust Cloud Minimum Ignition Energy Tester disperses a certain mass of dust specimen to be tested into the Hartmann tube device through a certain pressure of compressed air to form a cloud of dust, uses a specified spark energy to ignite the dust cloud, and obtains the minimum ignition energy of the dust specimen to be tested through a series of tests. It reflects the sensitivity of dust ignition from the energy point of view, and is suitable for evaluating the potential explosive hazard of dust clouds.

Applications

1. Chemical Industry: Determine the Material Effects (MI) of chemical dusts such as organic synthesis intermediates and plastic powders to guide explosion-proof safety design in production/storage processes;

2. Food Processing Industry: Test the MI of food dusts such as flour and sucrose powder to optimize safety measures for dust control in workshops;

3. Mining/Materials Industry: Assess the ignition risk of dusts such as coal dust, aluminum dust, and wood dust to assist in the configuration of explosion-proof facilities in mines and material processing plants;

4. Light Industry: Test the MI of tobacco powder and plant fiber powder to support workshop safety management and risk classification;

5. Safety Testing Institutions: Conduct compliance testing and certification for dust explosion risks based on standards such as ASTM and IEC.

Standards

ASTM E2019:Standard Test Method for Minimum Ignition Temperature of Dust Layers

IEC 61241-2-3:Electrical Apparatus for Use in Explosive Dust Atmospheres - Part 2-3: Test Methods - Determination of Minimum Ignition Temperature of Dust Layers

ISO/IEC 80079-20-2:Explosive Atmospheres - Part 20-2: Equipment Protection Levels (EPL) - Classification of Equipment for Dust Atmospheres

GB/T 16428:Test Method for Explosion Limits of Dust Clouds

Features

1. It has built - in commonly used international test standards, allowing for testing according to standard parameters or custom - setting.

2. During testing, only the ignition energy value needs to be input, and the instrument automatically selects the optimal combination of capacitance and voltage.

3. The high - voltage charging module automatically disconnects, improving operational safety.

4. The powder dispersion device is reasonably designed to ensure uniform dispersion of powder samples.

5. The instrument is flexible to use, with easy adjustment of the electrode spacing, spraying pressure, and delay time.

6. It automatically records the number of times the electrode ignites and reminds users to replace the electrodes in a timely manner to prevent electrode wear from affecting the test results.

7. The Hartmann tube is equipped with a lifting and rotating mechanism, which is convenient for cleaning and saves experimental time.

8. Remote ignition ensures the safety of experimenters.

9. User - level management enables the management and control of accounts at different levels.

10. The USB interface is plug - and - play, facilitating data management.

11. With professional industrial design, it is simple and elegant.

12. It has a user - friendly human - machine interaction, making it easy to learn, understand, and operate.

13. It is equipped with a 7 - inch color liquid - crystal touch screen that dynamically displays the experimental progress.

Technical Parameters

|

Operating Environment |

(5~45)℃, <85%RH |

|

General Purpose Mode |

1 mJ,3 mJ,10 mJ |

|

Spark Energy |

30 mJ,100 mJ,300 mJ,1000 mJ,3000mJ |

|

Custom Mode |

(1~3000)mJ, settable, step 1mJ |

|

Spark Energy |

(0~15)kV |

|

Charging Voltage |

No load, 1mH inductive load |

|

Discharge Load |

1.2L Hartmann Tube |

|

Experiment Vessel |

Diameter 2mm Tungsten Electrode |

|

Electrodes |

(2~10)mm, Adjustable |

|

Electrode Spacing |

High Voltage relay triggered,... Moving electrode trigger |

|

Electrode Trigger Mode |

20ms~180ms, adjustable |

|

Ignition Delay Time |

0.4MPa~0.7MPa, adjustable |

|

Powder Spray Pressure |

USB*2 |

|

Interfaces |

90~260VAC/47~63Hz |

|

Power |

300W |

Accessoriess

1. Hartmann tube testing device (core chamber for forming a uniform dust cloud)

2. Compressed air delivery assembly (including pressure regulation module for dust dispersion)

3. Spark ignition energy regulation assembly (provides different spark energies to suit testing needs)

4. Dust sample quantitative feeding device (precisely controls the quality of test dust)

5. Hartmann tube seal (ensures the sealing performance of the test chamber)

6. Calibration standard dust sample (calibration component for reference standards)

7. Data acquisition and analysis module (synchronously records ignition test data)

Test Procedures

1. Experimental Preparation: Check the integrity of the Hartmann tube, ignition assembly, and other accessories, and connect the compressed air delivery assembly.

2. Sample Preparation: Weigh the dust sample to be tested quantitatively and load it into the dust metering device.

3. Parameter Settings: Select the built-in reference standard (e.g., ASTM E2019) or customize the test parameters on the instrument interface.

4. Dust Cloud Formation: Start the compressed air system to disperse the dust into the Hartmann tube, forming a uniform dust cloud.

5. Ignition Test: Start the spark ignition assembly, gradually adjust the spark energy, and repeat the test to determine the minimum energy required to ignite the dust cloud.

6. Completion and Data Processing: After the test, shut down the equipment, clean the Hartmann tube and the feeding device, and export and analyze the minimum ignition energy (MIE) data.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Medical injection needle puncture force tester | The Medical Injection Needle Puncture Force Tester is a precision instrument designed to evaluate the puncture performance of medical needles. It s... | |

| Catheter bending resistance tester | The Catheter Bending Resistance Tester is a specialized instrument designed to evaluate the bending performance and flow characteristics of cathete... | |

| Flammability Tester for Aerosol Foams | Product Introduction This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 31.6 Flammabi... | |

| Guide pin anchoring force tester | The Guide Pin Anchoring Force Tester is designed to evaluate the anchoring performance of mammary positioning wires and guide needles. It ensures t... | |

| Metal Corrosivity Tester | The Metal Corrosivity Tester is used to determine the corrosivity of liquids and solids that may become liquid during transport. It conforms to the... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |