Thermal - Cold Cycle Testing Machine

The Thermal-Cold Cycle Testing Machine is a professional equipment used for high and low-temperature reliability testing. It is primarily used in fields such as electronics, electrical engineering, automotive, and aerospace, to test the performance of materials and components under extreme temperature conditions. It conforms to GB/T2423.1.2.3 standards and supports three test modes: high temperature, low temperature, and thermal shock. Rapid temperature switching can be achieved through a two-chamber or three-chamber structure.

Applications

1. Electronics and Electrical Engineering: Testing the temperature stability of chips, batteries, etc., to meet industry standards;

2. Automotive Industry: Verifying the temperature resistance of automotive electronics and body materials;

3. Materials Science: Screening the temperature tolerance of plastics and composite materials to support material selection;

4. Aerospace/Defense Industry: Adapting to extreme temperature change scenarios to ensure stable equipment operation;

5. Medical/Construction Materials: Verifying the temperature durability of medical equipment and building materials to meet compliance requirements.

Standards

BS 7291: Compliant for thermal cycling tests on thermoplastic pipe systems (1769 Series with pressure chamber).

Adaptive Certification: Configurable to meet ISO, ASTM, and EN standards upon request.

Features

Dual Models for Diverse Needs:

1769 Series (Pressurized): Operates up to114°Cwith integrated pressure chamber for BS 7291 compliance.

1770 Series (Non-Pressurized): Cost-efficient solution for tests up to95°C.

Smart Sample Management:

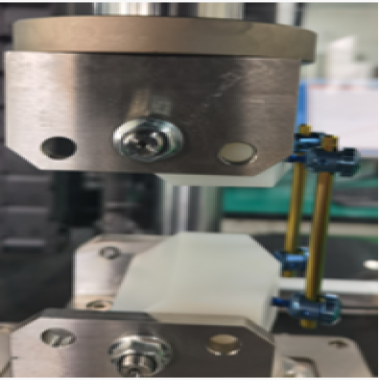

Adjustable tension rig with load cell (0–500N) for real-time strain monitoring.

Perforated wall panels and custom fixtures for irregularly shaped specimens.

Safety & Efficiency:

Dual-access doors (single/double-hinged) for ergonomic loading.

Self-cleaning water circuit minimizes maintenance downtime.

Connected Workflow:

IoT-ready controller with 7-day auto-sequencing and cloud data backup.

Multi-language HMI (English, French, German, Chinese) with audit trail logging.

Technical Parameters

| Specification | 1769 Series (Pressurized) | 1770 Series (Non-Pressurized) |

|---|---|---|

| Temperature Range | -20°C to 114°C | -20°C to 95°C |

| Max. Test Pressure | 16 bar (232 psi) | N/A |

| Flow Rate | 25 m³/h (108 GPM) | 25 m³/h (108 GPM) |

| Max. Sample Ø | 160 mm | 160 mm |

| Power Supply | 380V/50Hz 3-phase (CE certified) | 220V/60Hz single-phase (UL listed) |

| Chamber Volume | 850L (expandable to 1.200L) | 600L |

| Dimensions (W×D×H) | 1.200mm × 800mm × 1.900mm | 900mm × 700mm × 1.700mm |

| Weight | 680 kg (net) | 520 kg (net) |

Accessoriess

1.Chamber Access:

Single-hinged door (standard) or dual-swing doors for walk-in loading.

2.Sample Fixation:

Adjustable racks for pipes/fittings (Ø16mm–Ø160mm).

Custom perforated walls for bundled specimens.

3.Tension Control:

Motorized tension rig with 0.1N resolution load cell.

4.Extended Warranty:

3-year comprehensive coverage for critical components.

5.Calibration Kit:

NIST-traceable temperature/pressure sensors with certificate.

Test Procedures

1. Pre-test Preparation

Check that the instrument's power supply and cooling/heating systems are functioning correctly, replenish the circulating medium, clean any impurities from the test chamber, and calibrate the temperature sensor.

2. Sample Preparation and Installation

Cut the sample according to testing requirements, record the sample's basic information, place the sample smoothly into the test chamber, avoiding stacking, and ensure the sample does not touch the chamber walls.

3. Parameter Settings

Select the test mode via the control panel, set the high and low temperature thresholds, constant temperature duration, number of cycles, and heating/cooling rate. Save the parameters after confirming their accuracy.

4. Starting the Test

Close the test chamber door, press the start button, and the instrument will automatically run according to the set parameters, monitoring the panel temperature and operating status in real time.

5. Test Monitoring

During operation, observe the instrument for any abnormalities, record changes in the sample's state during the temperature cycling process, and prevent sudden malfunctions from affecting the test.

6. Test Completion and Cleaning

After reaching the set number of cycles, the instrument will automatically shut down. After the chamber temperature returns to room temperature, open the chamber door, remove the sample and record the test results, clean the test chamber, turn off the instrument power, and organize the test data.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Infusion Apparatus Leakage Positive Pressure Tester | The M102 Infusion Apparatus Leakage Positive Pressure Tester is designed to evaluate the airtightness and sealing performance of medical injection ... | |

| Spinal Pedicle Screw-Rod System Compressive Fatigue Testing Machine | Standard YY/T 0857-2011 (China): Specifies compression fatigue testing protocols for spinal pedicle screw-rod systems, including load ratios, freq... | |

| Industrial chillers | Standards ASHRAE 15(Safety Standard for Refrigeration Systems) ISO 5149(Refrigerating Systems and Heat Pumps) UL 1995(Heating and Cooling Equi... | |

| Safety Helmet Chin-strap Strength Tester | The Safety Helmet Chin-strap Strength Tester is designed to evaluate the tensile strength and reliability of chin straps on industrial, sports, and... | |

| Konan-Type Flammability Tester | Product Description Conforms to the UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 11.5.1 Test 1(b): Kernan... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |