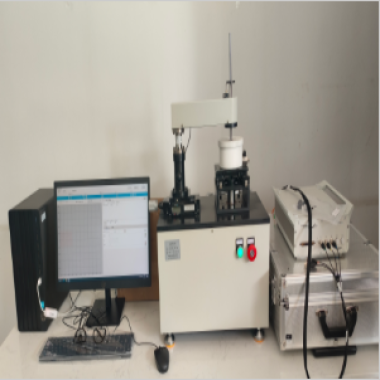

UV Viewing Cabinet

The UV Viewing Cabinet is a precision instrument designed to detect and analyze fluorescent substances in a wide range of materials. By providing controlled ultraviolet (UV) and visible light exposure, it allows accurate observation, comparison, and documentation of fluorescence for quality control, impurity detection, and material authentication.

Application

(1) Coatings and paints: Detect and analyze phosphors in plastics, paints, and coatings.

(2) Aluminum foil: Examine fluorescent substances in aluminum foil and related materials.

(3) Paper: Test for fluorescent substances in various types of paper.

(4) Plastics: Detect fluorescence in plastics and other polymer materials.

(5) Quality control: Evaluate material uniformity and detect impurities.

(6) Research and development: Study fluorescent behavior of new compounds or coatings.

(7) Non-destructive testing: Examine samples without damaging or altering them.

Standards

(1) GB/T 16422.3 – Fluorescent inspection methods for non-metallic materials.

(2) GB/T 14522 – Material fluorescence testing standards.

(3) ASTM G154 – Standard practice for fluorescent testing of non-metallic materials.

(4) ISO 4892-3 – Plastics exposure to laboratory light sources for fluorescence testing.

(5) SAE J2020 – Automotive exterior parts fluorescence inspection.

Features

(1) Integrated UV light sources at 254 nm (short-wave) and 365 nm (long-wave) for excitation of different fluorescent compounds.

(2) D65 standard visible light source for comparison under controlled white light conditions.

(3) Camera system for capturing and documenting sample fluorescence images.

(4) Light-tight chamber for controlled environment and operator protection.

(5) UV filter (200×50 mm) to regulate emitted UV light.

(6) Host unit for centralized control and image analysis.

(7) Picture comparison function for side-by-side observation of samples under UV or visible light.

(8) Non-destructive testing, supporting quality control, impurity detection, and material authentication.

Parameters

| Parameter | Specification |

|---|---|

| Ultraviolet wavelength | 254 nm, 365 nm |

| Filter size | 200 × 50 mm |

| Visible light | D65 standard illuminant |

| Power supply | AC 220V, 50Hz |

| Standard configuration | Host unit, picture comparison system |

Accessories

(1) Host unit

(2) Camera system for image capture

(3) UV filters

(4) Picture comparison system

(5) Power cable and manual

Test Procedures

(1) Place the sample inside the UV Viewing Cabinet.

(2) Select the UV wavelength (254 nm or 365 nm) or the visible light source (D65) as required.

(3) Activate the light source and allow the sample to be illuminated under controlled conditions.

(4) Observe the fluorescence visually or capture images using the integrated camera system.

(5) Use the picture comparison function to analyze differences between samples or compare with reference standards.

(6) Record and document the observations for quality control or R&D purposes.

Maintenance Information

(1) Keep the chamber clean and free from dust or residues that may affect UV exposure.

(2) Inspect UV lamps and filters periodically for damage or reduced output.

(3) Handle the camera system carefully and avoid exposure to excessive UV light.

(4) Ensure all electrical connections are secure and the power supply is stable.

(5) Avoid direct eye exposure to UV light during operation.

(6) Follow manufacturer guidelines for servicing and lamp replacement.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Gloss Meter | Standard The SpectroColor Pro S Series Gloss Meter adheres to stringent automotive interior quality control standards, includingISO 2813. ASTM D52... | |

| Keyboard Key Life Testing Machine | The Keyboard Key Life Testing Machine is designed to evaluate the durability and lifespan of keys and buttons across electronic devices. It is suit... | |

| Micro Controll Constant-Speed Friction Plate Tester | Standards GB5763-1998 brake linings for automobiles; GB/T5764-1998 brake linings for automobiles; GB/T5764-1998 brake linings for automobiles. ... | |

| Electrochemical Corrosion and Wear Testing Machine | Standard ASTM G119: A standard for evaluating synergistic corrosion-wear performance, particularly for biomedical implants in simulated body fluid... | |

| Xenon Arc Exposure Apparatus | Features and Benefits 1.The spectra of the xenon arc lamp and sunlight are highly convergent.Xenon arc exposure apparatusadopts quartz globe sea... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |