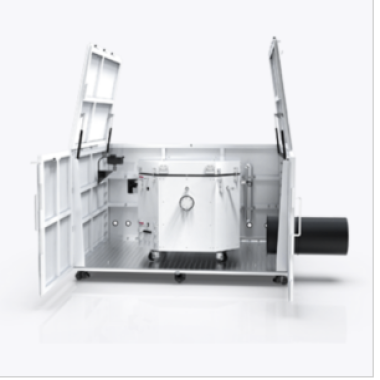

Safety Helmet High Temperature Pre-Treatment Chamber

The safety helmet high-temperature pre-treatment chamber is manufactured according to the GB/T2812-2019 standard for safety helmets and is primarily used for the high-temperature pre-treatment of safety helmets. It is widely used in special labor protection equipment supervision and inspection stations, building science research institutes, construction engineering quality testing stations, power departments, and safety helmet manufacturing enterprises.

Application

It is mainly used for the extremely high - temperature pre - treatment of safety helmets.

Standard

GB/T2812-2019:Test methods for safety helmets

Feature

Precise Temperature Control: Utilizing an advanced temperature control system, typically within a range of 50℃±2℃, to ensure the accuracy of test results.

Multi-Station Design: Equipped with a large-sized headform platform and test chamber, allowing for the simultaneous pre-treatment of 1-4 safety helmets, improving testing efficiency.

Intelligent Control: Features PLC touchscreen control or an intelligent control instrument for pre-setting test times and automatic alarm notifications, making operation simple and easy to learn.

Independent Temperature Measurement System: Equipped with a multi-channel temperature measurement system to collect temperature data from both the inside of the test chamber and the inside of the headform, ensuring accurate and uniform temperature control.

High-Efficiency Heating System: Employs a full stainless steel finned heating system, utilizing efficient heat conduction to improve energy efficiency and ensure that the safety helmet, from shell to straps, is subjected to realistic high-temperature testing.

Parameters

| Technical Parameter | Description |

|---|---|

| Test chamber temperature | Range: Room temperature - 200°C; Standard operating temperature: 150±5°C |

| Test time | Range: 0 - 99 minutes, adjustable; Standard: 60±2 minutes |

| Number of test samples | 1 - 4 helmets |

| Head mold temperature | 50°C±2°C |

| Test head mold | Wall thickness > 1.5mm; Size according to No.1 in GB2812; Made of aluminum alloy with a hollow interior |

| Temperature - measuring point of the head mold | Distance from the mid - point of the head mold < 40mm |

| Instrument dimensions | 8707101100mm |

Accessoriess

Equipped with a 5-channel temperature measurement system, which collects data from both the interior of the test chamber and the interiors of the four head forms, with independent data acquisition and output for each unit.

Equipped with 5 independent airflow circulation devices to ensure that the temperature inside the test chamber and the head forms meets the standard requirements.

Equipped with four head forms made of aluminum alloy, conforming to GB2812 standard (Type 1).

Test Procedures

Open the chamber door and place the safety helmet to be tested on the shelf inside the heating chamber. Close the chamber door.

Connect the power supply and turn on the power switch; the power indicator light will illuminate.

The instrument will begin heating, and the temperature controller will display the temperature inside the chamber.

When the temperature reaches the required level, the timer will start. After the set time has elapsed, the operation will end.

The lower row of the display window will show "END," and the buzzer will sound for 30 seconds before all outputs are switched off.

After the test is complete, if no further testing is required, please turn off the power. The operating lights include the "RUN/AT" indicator light, the heating output indicator light, and the over-temperature alarm indicator light. During operation and use, the instrument enters the normal display state 3 seconds after power-on. The PV displays the actual temperature, and the SV displays the set temperature and operating time. To set the temperature and time, press "SET" to enter the temperature setting state, and use the shift and up/down keys to modify the set values.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Suture Needle Penetration and Bending Strength Tester | The Suture Needle Penetration and Bending Strength Tester is a device used to test the penetration performance and strength of medical suture needl... | |

| Flip Phone Durability Tester | Product Introduction: Mobile clamshell testing machine is a special equipment for mobile clamshell fatigue test. Its structure design is reason... | |

| Photovoltaic module damp heat test chamber | The Photovoltaic Module Damp Heat Test Chamber is designed to simulate long-term tropical aging conditions for photovoltaic modules and related ele... | |

| Molten Metal Splash Resistance Test Equipment | Product Introduction: Projections of molten metal drops at a point on a vertical oriented test specimen and measurement of the number of the drops... | |

| Battery Adiabatic Calorimeter | Reference Standards GB/T 36276 - 2023 *Lithium - ion Batteries for Electric Power Energy Storage UL 9540A ASTM E1981 - 98(2012) SN/T 3078.1 - 201... |

Похожие товары

| Falling Sand Abrasion Test machine | Продавец: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Продавец: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Продавец: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Продавец: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |