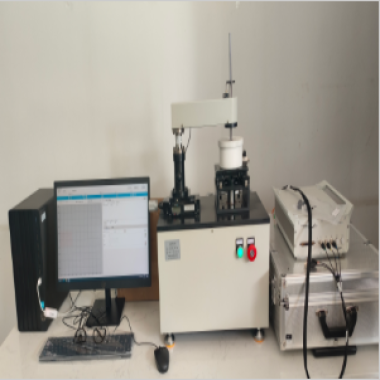

Electrochemical Corrosion and Wear Testing Machine

Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace, and other fields. These devices can evaluate the tribological performance of materials in specific corrosive environments, helping researchers and engineers select, improve, and protect materials.

Applications

Material Screening: Metals, polymers, and coatings for automotive, aerospace, and offshore sectors.

Coating Optimization: Evaluation of DLC, ceramic, and anti-corrosion coatings under combined stress.

Tribological Design: Lubricant and surface treatment development for bearings and implants.

Quality Assurance: Batch consistency testing for corrosion-resistant components.

Standard

ASTM G119: A standard for evaluating synergistic corrosion-wear performance, particularly for biomedical implants in simulated body fluids.

ASTM G99: A pin-on-disc friction test method to measure material friction coefficients and wear resistance across industries like automotive and aerospace.

ISO 20808: A ball-on-disc test protocol for characterizing friction and wear behavior of monolithic advanced ceramics in precision engineering applications.

Product Advantages

Precision Dual-Mode Testing: Combines electrochemical corrosion analysis and friction-wear testing for comprehensive material degradation studies.

Real-World Simulation: Replicates combined mechanical stress and chemical exposure to accelerate performance validation.

High-Accuracy Measurements: 0.2% FS accuracy for load, friction, and corrosion data ensures reliable R&D decisions.

Flexible Configuration: Adjustable stroke, speed, and load ranges accommodate diverse testing protocols.

Compact Design: Space-efficient footprint (400×300×600 mm) with 50 kg weight for laboratory versatility.

Product Features

Electrochemical Corrosion Module:

Measures polarization curves and electrochemical impedance spectroscopy (EIS) in corrosive media.

Supports 300 ml electrolyte capacity for extended testing.

Friction-Wear Module:

Reciprocating sliding frequency: 0.1–5 Hz; adjustable stroke: 0.5–25 mm.

X/Z-axis travel: 0–40 mm (X) and 0–150 mm (Z) for multi-directional wear analysis.

Sample Versatility:

Lower specimen size: 30–80 mm; upper specimen: Ф4–Ф6 mm (ball/pin).

Ball sample reservoir: 120×90×50 mm for standardized testing.

Synergistic Testing: Simultaneous corrosion-wear evaluation for marine, chemical, and automotive applications.

Data Integration: Real-time friction (≤50 N) and corrosion metrics with CSV/Excel export.

Parameters

| Parameter | Specification |

|---|---|

| Test Load Range | 30–1000 g (weight loading); 10–50 N (automatic) |

| Accuracy | 0.2% FS (full scale) |

| Sliding Frequency | 0.1–5 Hz |

| Stroke Adjustment | 0.5–25 mm (reciprocating) |

| X/Z-Axis Travel | X: 0–40 mm; Z: 0–150 mm |

| Sample Sizes | Lower: 30–80 mm; Upper: Ф4–Ф6 mm |

| Electrolyte Capacity | 300 ml |

| Friction Measurement | ≤50 N; 0.2% FS accuracy |

| Main Unit Dimensions | 400 mm (W) × 300 mm (D) × 600 mm (H) |

| Weight | 50 kg |

| Power Supply | 220 VAC ±10%, 50/60 Hz, 1.5 kVA |

| Environmental Control | Temperature: -10°C–100°C (optional upgrade) |

Accessoriess

Corrosion testing chamber

Specially designed fixtures

Three-electrode system

Integrated electrochemical workstation

Specially designed liquid cell, etc.

Test Procedures

Prepare the sample by cutting or machining it to the appropriate size, and then polish and clean the sample surface.

Mount the prepared sample onto the fixture of the test platform, ensuring that the sample is securely mounted and has good contact with the counter-part.

Select a suitable electrolyte and pour it into the electrolyte tank, then install the electrode system and connect it to the electrochemical workstation.

Set the various test parameters on the control panel, including the loading force and friction speed for friction and wear testing, and the potential and current parameters for electrochemical corrosion testing.

After setting the parameters, perform a no-load test run to check if all machine components are functioning properly.

Once confirmed, officially start the test.

During the test, the operator should closely monitor the data changes on the display screen and observe the surface condition of the sample.

After the test is completed, turn off the machine power, remove the sample, observe and analyze the sample, record the test data, clean the equipment, drain the electrolyte, and perform cleaning and maintenance on the machine.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Initial Adhesion Tester | The initial - tack tester, also known as the initial - tack property tester or adhesive tape tackiness tester, is an instrument specifically used t... | |

| Gas Oxidizing Property Tester | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylinder Valve Exhaust Ports by Determination of Combusti... | |

| Large diameter blasting test machine | The large-diameter blasting test machine can perform continuous (linear) pressure testing of pipes according to ASTM D 1599 standard. The pressuriz... | |

| DSC Differential Scanning Calorimeter | The Differential Scanning Calorimeter (DSC) measures the heat flow to or from a sample under controlled heating conditions. A small amount of sampl... | |

| Liquid Spontaneous ignition point tester | Product Description complies with GB/T 21860-2008 “Test Method for Autoignition Temperature of Liquid Chemicals” and ASTM E “Tes... |

Похожие товары

| Falling Sand Abrasion Test machine | Продавец: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Продавец: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Продавец: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Продавец: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |