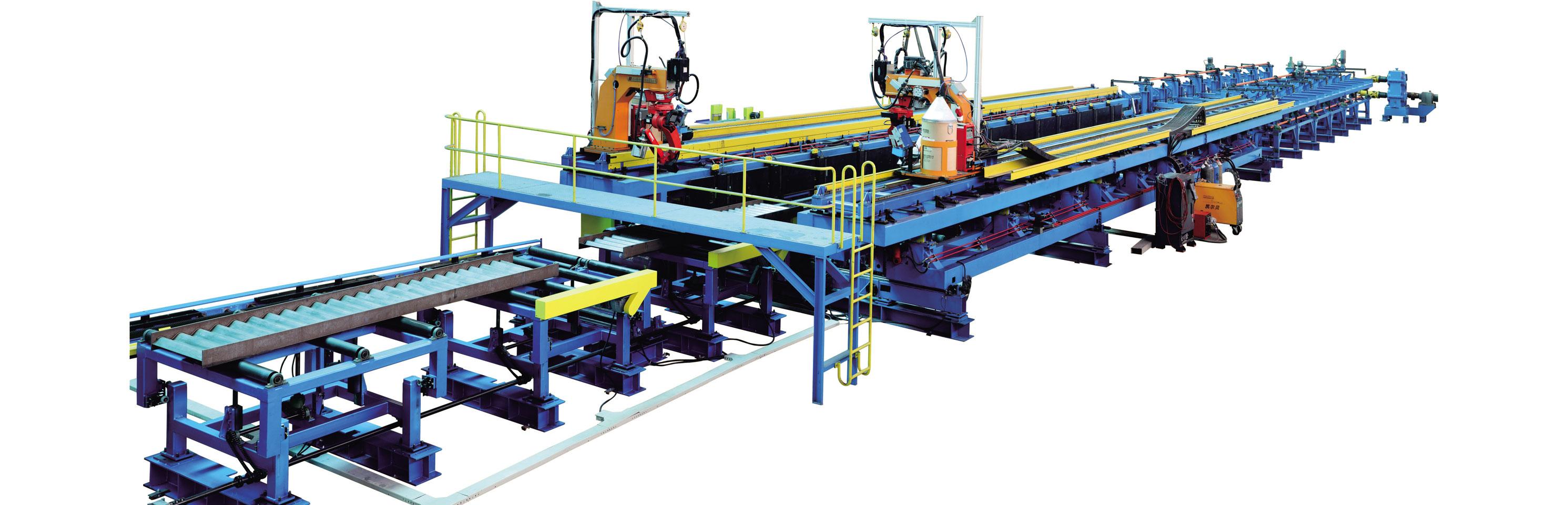

Corrugated Web H-beam Welding Line

The corrugated web beamautomatic welding machine adopts the welding robot originally from Italy which automatically controls the works such as the whole Line laser scanning, two positions welding, welding gun changing, crosssection cutting and so on. This machine has the features of high quality, high efficiency, full-automation and so on.

It can cut, assemble and weld the tapered beam. The welding speed of this production line is about 700 mm/min (max. projected linear average speed). For the raw materials to feed into the machine, load the suitable coil onto the decoiler or simply feed the flat plate are both OK.

The length, height and thickness the machine can produce:

H-beam length: 4-16 m

H-beam height: 300-1500 mm

Corrugated web thickness: 2-6 mm(≤235 MPa), 2-4 mm(≤345MPa)

H-beam flat web thickness: 4-8 mm

Video of Corrugated Web H-beam Welding Line

Corrugated web H-beam is a new construction materials. It is widely used in bridge, column, single and multiple bay frame construction. The surface is corrugated, and it can save steel 20%~60% under the same yield strength with each beam with flat webs, especially it has high cost performance in large span, crane beam, and so on. The span of 1.5 meters H-beam with corrugated webs can reach 40 meters. The JBH automatic corrugated web H-beam welding line is developed by Zhejiang Jinggong Science & Technology Co., Ltd.. The H-beam with corrugated webs use the original binding welding robot from Italy with automatic control to finish the work such as whole line laser scan, two positions welding, changing welding gun, cross-section cutting, and so on.

The machine has high quality, high efficiency, full automation, and so on. It consists of slitting and cutting length devices, web panel forming machine, flange web feeding machine, h-beam with corrugated webs robot automatic welding machine, variable cross-section cutting, stacking system, and so on.

In order to promote the use of H-beam with corrugated webs. Zhejiang JinggongScience & Technology Co., Ltd., Tongji University in Shanghai, Open Steel Structure, and other companies made the product standard for the industry. And in september 2010, it passed the review.

Parameter OfCorrugated Web H-beam Welding Line

|

Item |

Parameter |

|||||

|

Corrugated web forming machine |

Suitable raw material |

Yield strength(Mpa) |

≤345 |

|||

|

Steel thickness(mm) |

2-6(≤235Mpa): 2-4(≤345Mpa) |

|||||

|

Steel width (mm) |

350-1500 |

|||||

|

Profile dimension |

Wave height(mm) |

40-50 |

||||

|

Distance of waves(mm) |

(About)155 |

|||||

|

Steel feeding mode |

Conveyor |

|||||

|

Corrugate web output mode |

Transmission chain |

|||||

|

Feeding power(kw) |

30 |

|||||

|

Total weight (T) |

(About)11 |

|||||

|

Dimension (mm) 6235×1640×2500 |

||||||

|

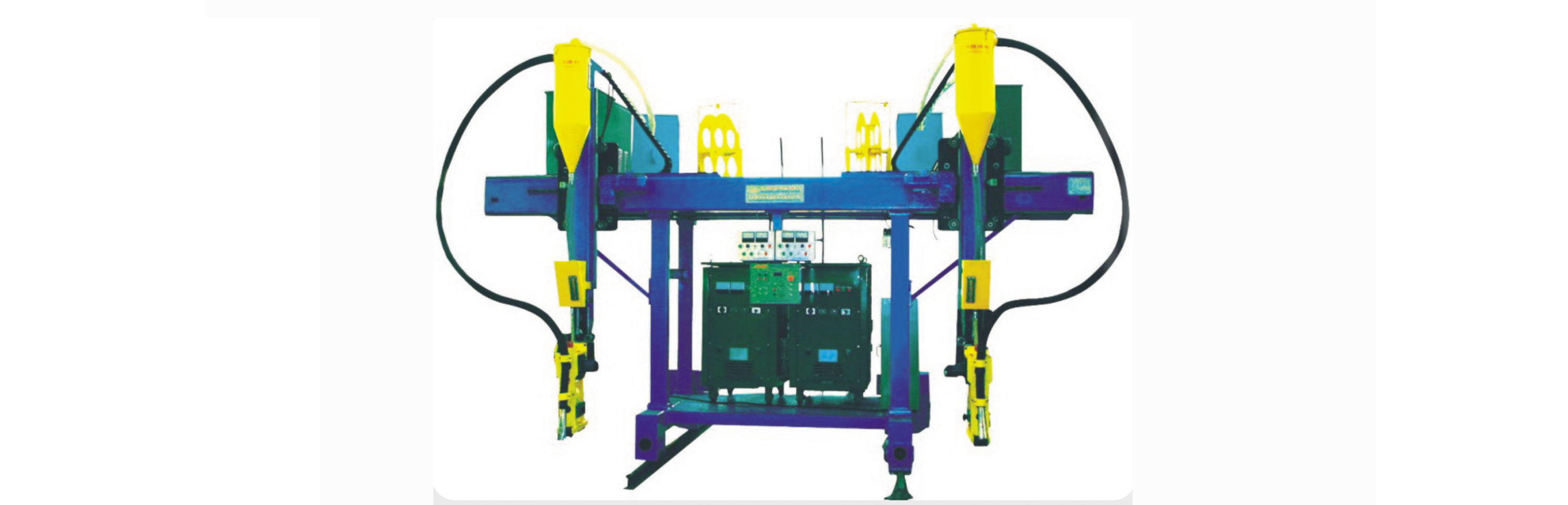

Corrugated web H-beam automatic robot welding machine |

Work-piece dimension (mm) |

Work-piece length |

4000-20000 |

|||

|

Web thickness |

2-6 |

|||||

|

Webheight |

350-1500 |

|||||

|

Flange thickness |

10-30 |

|||||

|

Flange width |

150-500 |

|||||

|

Welding mode |

Imported robot two-position welding at the same time |

|||||

|

Welding type |

CO2 welding |

Corrugate scanning |

Whole line laser scanning |

|||

|

Cutting type |

Plasma cutting |

Control mode |

Automatic control |

|||

|

Scanning speed (mm/s) |

≥600 |

Welding speed(mm/min) |

||||

|

Total power (kw) |

132 |

|||||

|

Dimension(mm) |

24000×6500×3500 |

|||||

|

Total weight(T) |

(About)41 |

|||||

|

Total power (kw) |

195(Except slitting/cutting line) |

|||||

|

Total weight (T) |

86(slitting/cutting line) |

|||||

|

Dimension (mm) |

67550×8500×3500(Except slitting/cutting line) |

|||||

Special features about Corrugated Web H-beam Welding Line

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Characteristics of Rockwool Sandwich Panel Machine | The rockwool sandwichpanel machine and its production process realize that the rockwool and steel plate can be combined into a whole through automa... | |

| Gantry Submerged Arc Welding Machine | Thegantry welding machinecan replace the cantilever submerged gantry weldingmachine, and can choose unipolar or multipolar welding, the landfill hi... | |

| Downspout Roll Forming Machine | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the colored steel sheet and whipstitch it. Thedownspout... | |

| What are the Specifications of Foam Sandwich Panels and Rock Wool Sandwich Panels in the Sandwich Panel Machine? | What are the specifications of foam sandwich panels and rockwool sandwich panel specificationin the sandwich panel machineline? Foam sandwich pa... | |

| CNC Flame Cutting Machine | The flame cutting machine for saleis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen... |

Похожие товары

| G26030-1 Single Package Lithium-Ion Lawn Mower | Продавец: Zhejiang Huaqi Information Technology Co., LTD | Rated voltage: 20V No-load speed: Low speed 3500/high-speed 5500±10%rpm No-load current: 5... | |

| Замена катушки триммера для бензинового триммера | Продавец: SENWART - Поставщик профессиональных бензопил и кусторезов в Китае | Краткие сведенияМесто происхождения: Чжэцзян, Китай.Модель: Кусторез SENWART HC250/HC260/HC330/HC... | |

| Corrugated Web H-beam Welding Line | Продавец: Zhejiang Jinggong Science & Technology Co., Ltd. | The corrugated web beamautomatic welding machine adopts the welding robot originally from Italy w... | |

| Эва компаунда губки | Продавец: Чанчжоу DayeTengfei Губка ООО | Листинг Описание отличайте сопротивлением ссадины, твердостью, анти-вибрацииУпаковкаИндустриальны... |