Reverse-Engineered Service

What is Reverse Engineering?

Reverse engineering is to obtain the point cloud data of the physical model by using the three-dimensional digital scanning of the existing physical model in the case that the design drawings are incomplete or even without the design drawings or CAD models, and the point cloud data is calculated and used. Processing is done to form a digital model for product redesign and CNC machining. A process includes two steps: the first step is to scan the physical model and the second step is to createa three-dimensional model.

Advantages of Reverse Engineering

To shorten the product design and development cycle, speed up the replacement speed of the products

To reduce the cost and risk of developing new products;

To speed up the geometric and Serialization Design for the products;

It is suitable for both single piece and small batch production, especially benefit for making molds.

With more than 20 years of 3d scanning reverse engineering service and 3D copying experience, we have successfully provided professional reverse engineering services for customers in reverse engineering projects of automotive manufacturing, aerospace, mold manufacturing, electronics, consumer, medical, cultural relics, sculpture, construction, scientific research and other industries. The solution helps industry customers shorten the development cycle, increase production efficiency and improve product quality.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| What is 3D Printing Service? | Are you looking for rapid prototype service china? 3D printing technology is a collective term for a series of rapid prototyping technologies, the ... | |

| Yacht Model Making Case Study | Project name:Yacht model Material: ABS engineering plastics Process: CNC machining Post treatment: Painting, plating Qty: 1 set Advantages: high pr... | |

| Vacuum Casting Services | What is the Vacuum Casting? The vacuum casting technology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone m... | |

| Sheet metal processing or sheet metal fabrication includes: folding, shearing, punching, welding, riveting, splicing and other processes. In general, the process of forming a sheet by hand or mechanic | The china vacuum castingtechnology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and i... | |

| What is Mass Production? | mass production and batch productionrefers to the continuous repetition of the manufacture of the same products in a longer period of production. H... |

Похожие товары

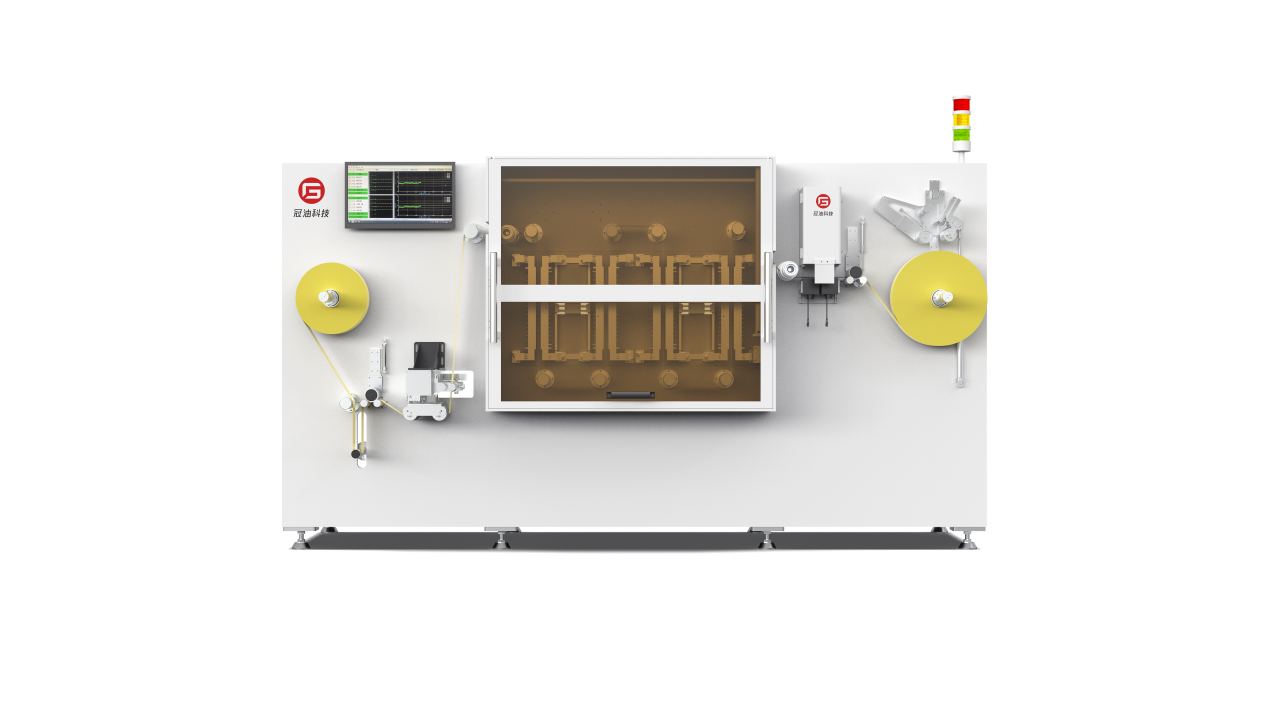

| The Single Workstation Electrostatic Perforating Machine | Продавец: Wuhan Guan You Technology Co., Ltd. | Одностанционная электростатическая перфораторная машинаОдностанционная электростатическая перфора... | |

| YZH WHEN1500 Стационарный гидравлический манипулятор | Продавец: Шаньдунская компания базовой инженерии | Ниже приводится подробное описание стационарной гидравлической стрелы для демонтажа YZH WHEN1500,... | |

| YZH WHEN1410 Стационарный дробилка | Продавец: Шаньдунская компания базовой инженерии | YZH WHEN1410 Стационарный педестальный рокбрейкер - это специализированное оборудование, предназн... | |

| JY-160S2 Standard Plastic Injection Machine | Продавец: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Экструзионная линия для производства ДПК террасной доски | Продавец: Qingdao Trusty Plastic Machinery Co.,Ltd | Древесно-полимерный композит ДПК, в основном составляет из ПЭ гранулы и древесного порошка, в отл... |