Reverse-Engineered Service

What is Reverse Engineering?

Reverse engineering is to obtain the point cloud data of the physical model by using the three-dimensional digital scanning of the existing physical model in the case that the design drawings are incomplete or even without the design drawings or CAD models, and the point cloud data is calculated and used. Processing is done to form a digital model for product redesign and CNC machining. A process includes two steps: the first step is to scan the physical model and the second step is to createa three-dimensional model.

Advantages of Reverse Engineering

To shorten the product design and development cycle, speed up the replacement speed of the products

To reduce the cost and risk of developing new products;

To speed up the geometric and Serialization Design for the products;

It is suitable for both single piece and small batch production, especially benefit for making molds.

With more than 20 years of 3d scanning reverse engineering service and 3D copying experience, we have successfully provided professional reverse engineering services for customers in reverse engineering projects of automotive manufacturing, aerospace, mold manufacturing, electronics, consumer, medical, cultural relics, sculpture, construction, scientific research and other industries. The solution helps industry customers shorten the development cycle, increase production efficiency and improve product quality.

Send product request

Other supplier products

| Yacht Model Making Case Study | Project name:Yacht model Material: ABS engineering plastics Process: CNC machining Post treatment: Painting, plating Qty: 1 set Advantages: high pr... | |

| 3D Printing Services | What is 3D Printing Service? 3D printing technology is a collective term for a series of rapid prototyping technologies, the basic principle of whi... | |

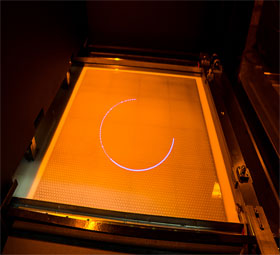

| ProtoFab SLA200 DLC | Stereolithography SLA 3D Printer for Sale- Compact Master Fine Workmanship & Top Quality Components Fine Workmanship & Top Quality Componen... | |

| Injection Mould Service | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| PFM1500 Automated vacuum casting system | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... |

Same products

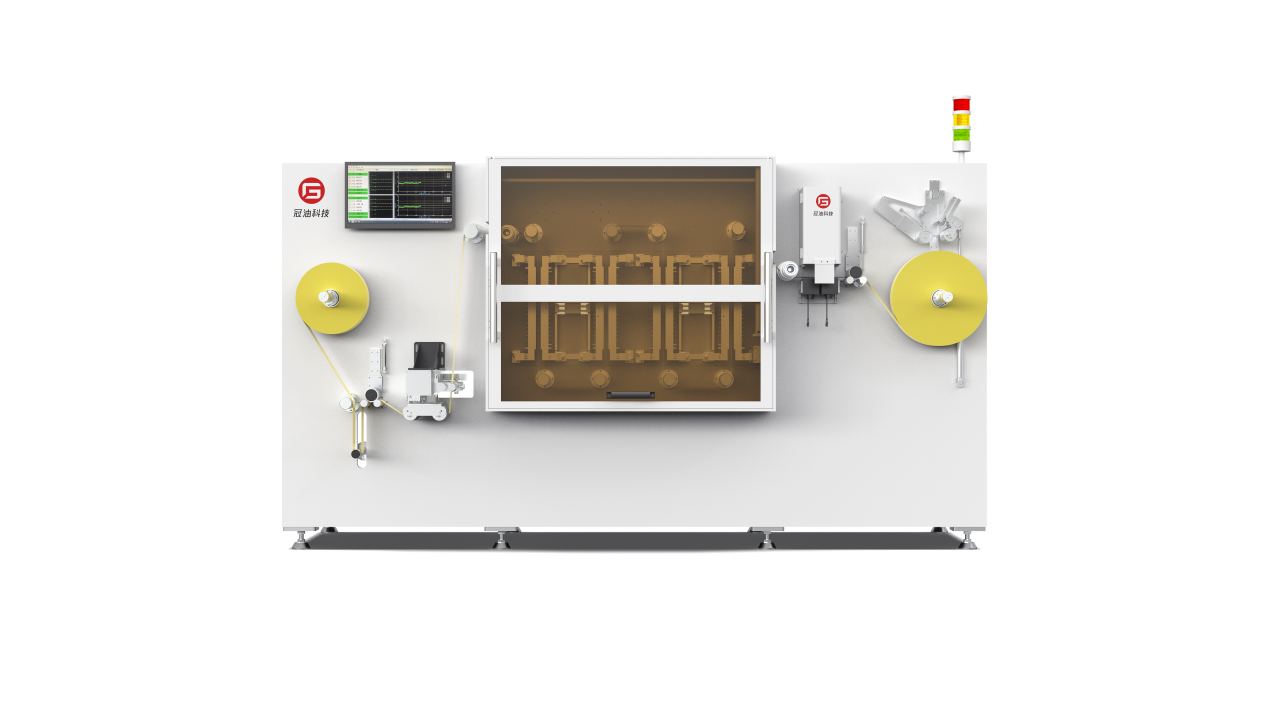

| The Single Workstation Electrostatic Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | The single workstation electrostatic perforating machineis a professional cigarette paper static ... | |

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |