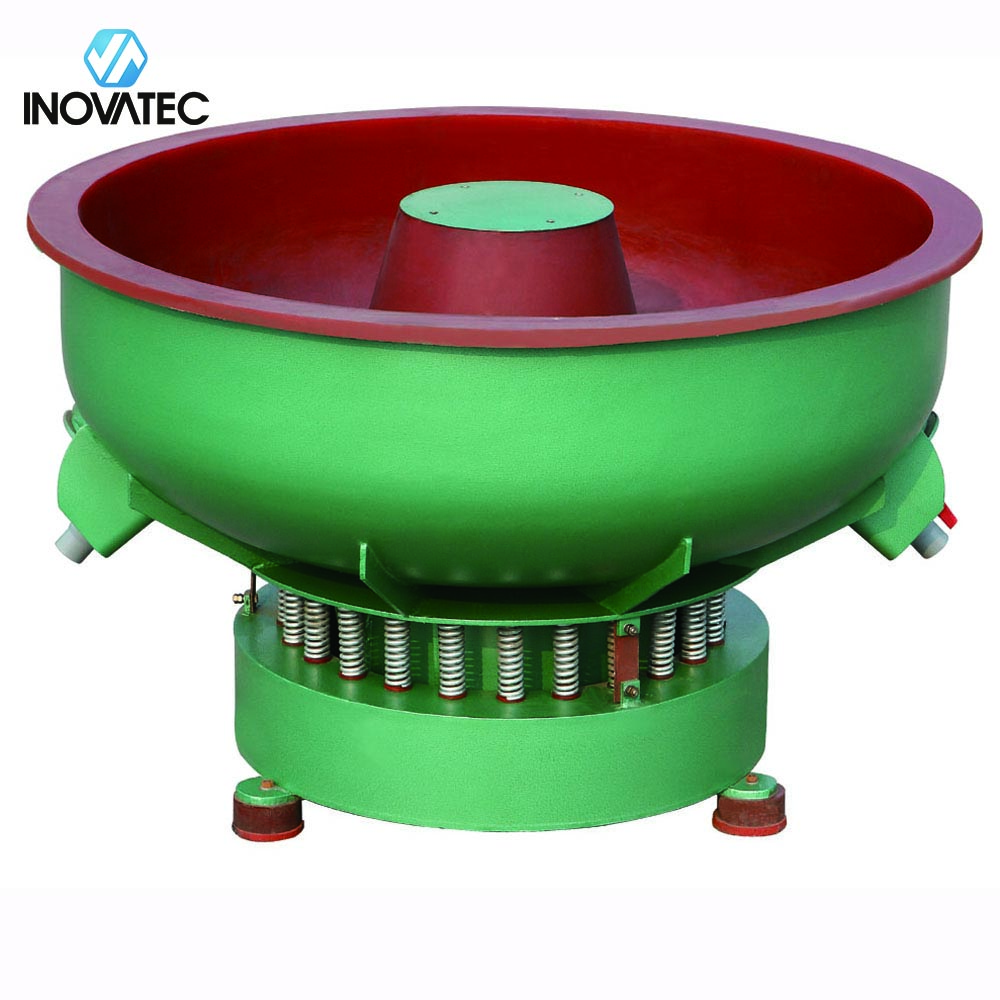

Cutlery Polishing Machine-Vibratory Polisher

Standard Features:

- Effective motor position for Excellent Vibration.

- High tensile bolts and nuts for long service life of motor and machinery.

- Efficient removal of process fluid for best surface finish.

- High efficient motor.

- Bowls shot blasted before and after Polyurethane lining for painting.

- All internal welds ground smooth.

- Anti rotation motor locking plate provided.

- Bowls Surface finishing is Stress relived and strengthened with shot blasting process

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Stainless tumbling media | Steel Tumbling Media allows for faster finishing times, eliminates the need for expensive, consumable compound solutions and rust inhibitors, and r... | |

| Zirconia ceramic ball – zirconia polishing ball | Introduction: Innova ZR-320 Ceramic Beads provides a higher wear resistance than porcelian media RP, which can be used as a cost-effective ultra-fi... | |

| Corn cob tumbling media – corn cob for cleaning and drying | Crushed and graded corncobs are usually used to dry parts as they absorb the water from wet parts.This eliminates watermarks or stains that are obj... | |

| Centrifugal disk finishing machine – centrifugal disc polishing machine | Feature Tilting angle of processing bowl up to 135° Optional circular pipe to rinsing and compound dosing Gap adjustment for machine for disc ... | |

| Vibratory finishing machine for Roto finish | Standard Features: Easy to change the separation deck Heavy-duty long service vibration motor Optional VFD (Variable Frequency Drive to control mo... |