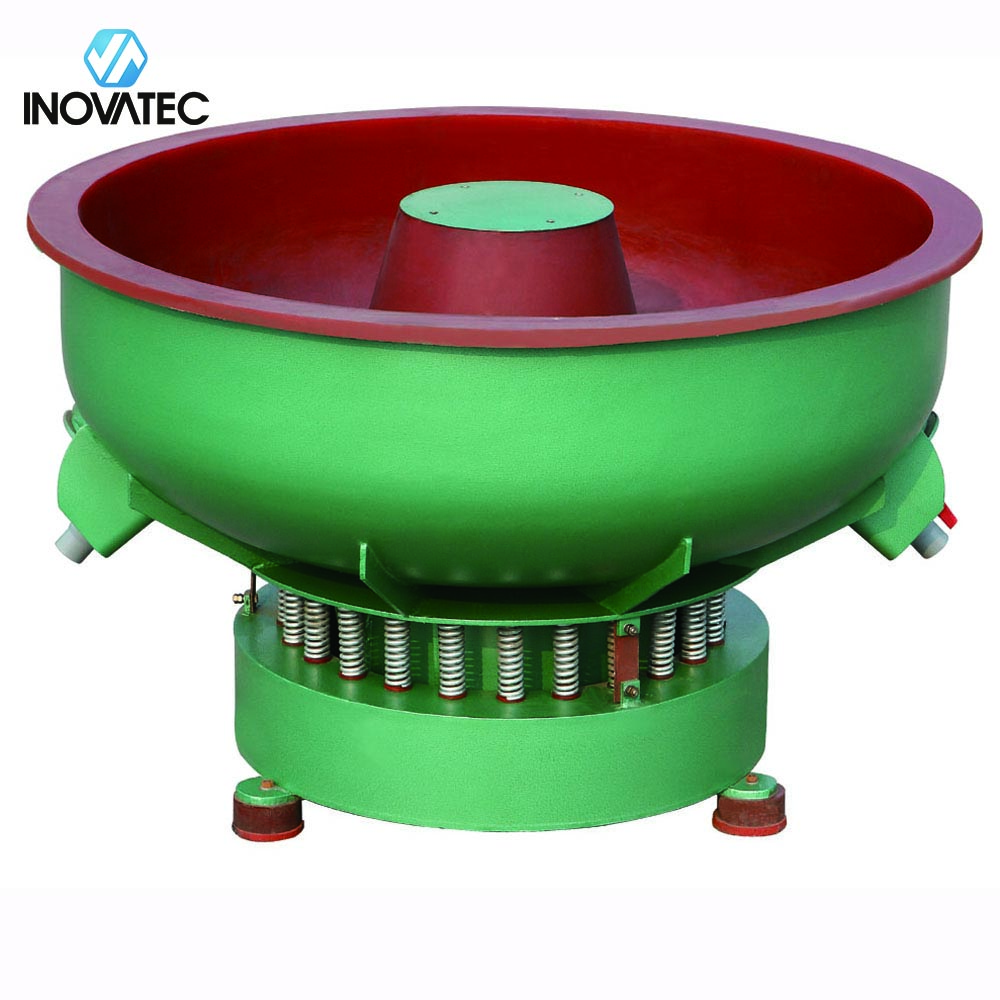

Cutlery Polishing Machine-Vibratory Polisher

Standard Features:

- Effective motor position for Excellent Vibration.

- High tensile bolts and nuts for long service life of motor and machinery.

- Efficient removal of process fluid for best surface finish.

- High efficient motor.

- Bowls shot blasted before and after Polyurethane lining for painting.

- All internal welds ground smooth.

- Anti rotation motor locking plate provided.

- Bowls Surface finishing is Stress relived and strengthened with shot blasting process

Send product request

Other supplier products

| Ceramic deburring media – RMB/D1 polishing abrasive | RMB/D1 ceramic grinding media is produced by mixing porcelain, kaolin,clay, river clay together with brown alumina oxide abrasives. The wet materi... | |

| Centrifugal dryer – Spin Dryer | Centrifugal Dryers also called spin dryer. They are typically used when parts are being dewatering and drying in bulk. The parts may be placed into... | |

| Stainless tumbling media | Steel Tumbling Media allows for faster finishing times, eliminates the need for expensive, consumable compound solutions and rust inhibitors, and r... | |

| Zero Gap Centrifugal Disc Finishing Machine Otec Design CF series | Feature: Highly user friendly The rotational speed, machine running time (forward/backward respectively), compound dosing as well as other process... | |

| Centrifugal disk finishing machine – centrifugal disc polishing machine | Feature Tilting angle of processing bowl up to 135° Optional circular pipe to rinsing and compound dosing Gap adjustment for machine for disc ... |