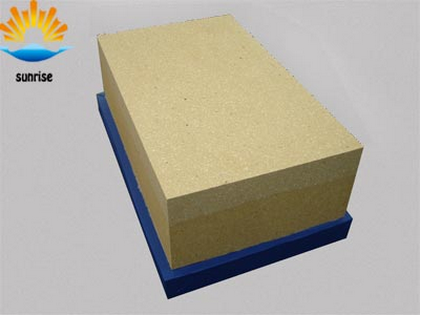

Big Fireclay Bottom Block

Description:

Using big vibrating table and adopting special castables, the company produces furnace large fireclay blocks with vibrate moulding technology. The physical and chemical properties and appearance of the blocks have exceeded the national standards. The resistant ability to molten glass of the products is better than that of fanditional casting process products and ramming products. The products are especially suitable to build the bottom of furnace, cooling and working end side wall of glass furnace.

Specifications:

1. Low permanent linear change on reheating

2. High dense structure

3. Good Thermal Shock Stability

Advantages:

1. Good wear-resistance;

2. Corrosion-resistant;

3. Various shapes;

4. High quality;

Другие товары поставщика

|

|

Sillimanite Brick |

DescriptionSilimanite brick is a kind of refractoriness which made by silimaniteand other minerals. And silimanite can be transformed to be mullite... |

|

|

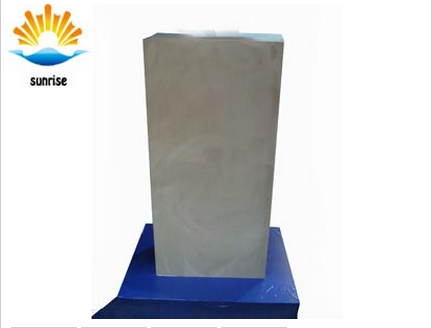

Fused cast Alumina Block TY-M |

Fused cast Alumina Block TY-MDescriptionFused cast Alumina Block TY-M is formed by the compact structure of alpha alumina and beta alumina crystals... |

|

|

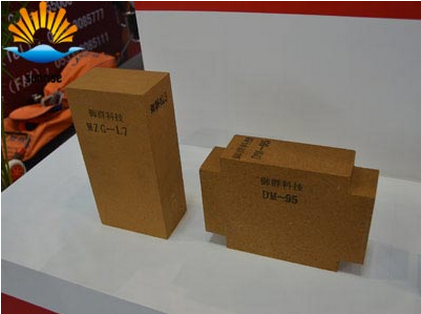

Fused Magnesia Brick DMZ-96 |

Specifications1.Fused Magnesia Brick Refractory2.CCS:60mpa,RUL:17003.Good erosion resistance4.High quality5.Reasonable priceFused Magnesia Brick Fe... |

|

|

Fused cast Alumina Block TY-M |

Fused cast Alumina Block TY-MDescriptionFused cast Alumina Block TY-M is formed by the compact structure of alpha alumina and beta alumina crystals... |

|

|

Fused Cast High Zirconia Block |

Fused cast high zirconia bricks descriptionThe series of TY-Z are fused cast high zirconia refractories which are specially designed refractory for... |

Все товары поставщика

Похожие товары