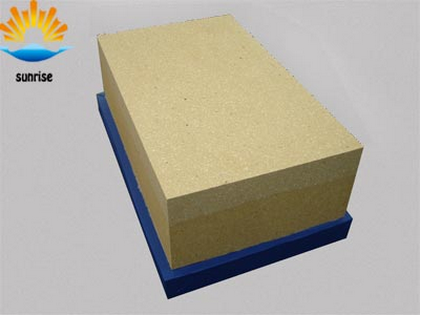

Big Fireclay Bottom Block

Description:

Using big vibrating table and adopting special castables, the company produces furnace large fireclay blocks with vibrate moulding technology. The physical and chemical properties and appearance of the blocks have exceeded the national standards. The resistant ability to molten glass of the products is better than that of fanditional casting process products and ramming products. The products are especially suitable to build the bottom of furnace, cooling and working end side wall of glass furnace.

Specifications:

1. Low permanent linear change on reheating

2. High dense structure

3. Good Thermal Shock Stability

Advantages:

1. Good wear-resistance;

2. Corrosion-resistant;

3. Various shapes;

4. High quality;

Other supplier products

|

|

Light insulation board manufacturing method |

Light insulation board refers to a heat insulation board with a bulk density of less than 850kg/m3 and a thickness of less than 6cm. This insulatio... |

|

|

High Alumina Insulating Brick |

DescriptionHigh alumina insulating bricks are also known as high alumina heat insulating bricks. It is a new type of lightweight insulating materia... |

|

|

Refractories the most important performance is the anti-erosion ability |

The part of the clarification that is in contact with the glass is in the same environment as the glass in the melting part, except that this part ... |

|

|

Mullite Bricks |

Description:Mullite brick IS characterized by good high temperature resistance and good thermal shock resistance, whick comes into being mullite th... |

|

|

Zircon Mullite Brick |

Zircon mullite brick selected high quality mullite sand and zircon powder as its main raw material. Molded by high pressure and sintered by high te... |

供应产品

Same products