Precision Injection Molding

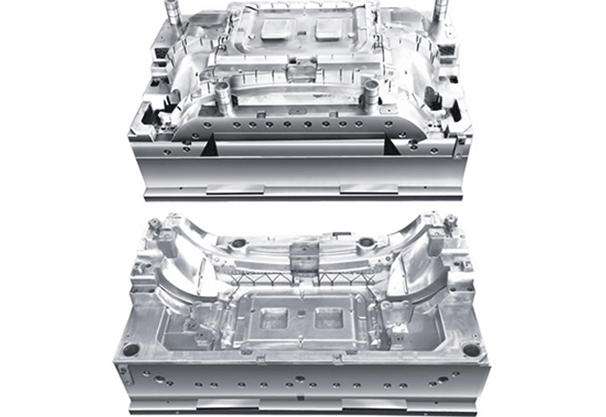

At Packson, we specialize in manufacturing custom precision mold partsand machined parts that meet or exceed international quality standards, including ISO 9001 and 13485. Our team is dedicated to building custom, durable, high-quality precision moulds and componentswith the spirit of craftsmanship.

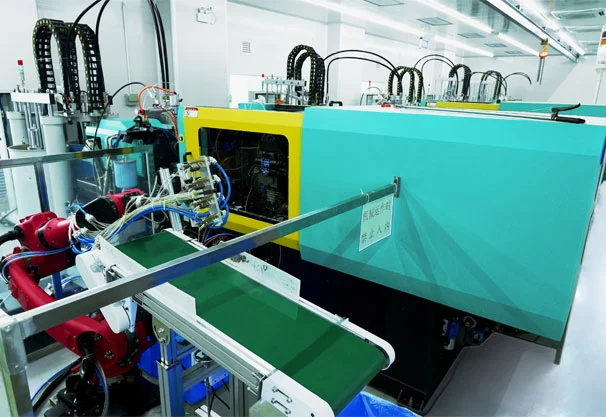

We take pride in our precision machining process, which is led by engineers with over ten years of experience. This process enables us to provide our customers with more efficient, high-precision, and economical designs and products. We are committed to delivering precision moulding and mouldsthat consistently meet or exceed industry-standard tolerances, up to ±0.005mm.To ensure the quality of our products, we use precise equipment for production and manufacture. We follow ISO 9001 and ISO 13485 quality control processes to ensure that every product meets our high standards. Our world-class production and testing equipment, including KEYENCE, Makino, CHARMILLES, Zeiss, and NISSEI, provides a strong guarantee for the precision of your products.

Precision mold parts must meet certain performance requirements to ensure their durability and longevity.

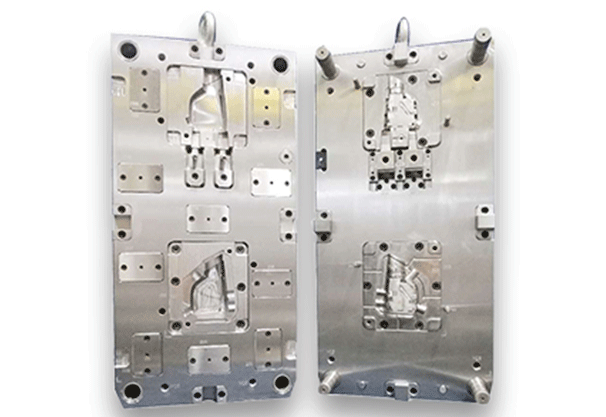

The Components of Precision Moulds

The success of precision mouldincludes the following:

Precise control of the mold cavity size

Precision of parting surface

Exact solution of material

Strict requirement for a tolerance

Venting design

Material flowing

Cooling system

Choosing of steel material

Overall excellent tooling design

Process of Precision Mould

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer

Send us your part 3D to get your mold and part quote

Confirm quotation and order issues, Packson starts the mold and precision mold parts order process

Making DFM and create processing solution

Tooling design review by Packson engineers

Get approval of the design, Packson start building your injection mold

Customer checks samples for approval

Part mass production begins

Applications of Precision Mould

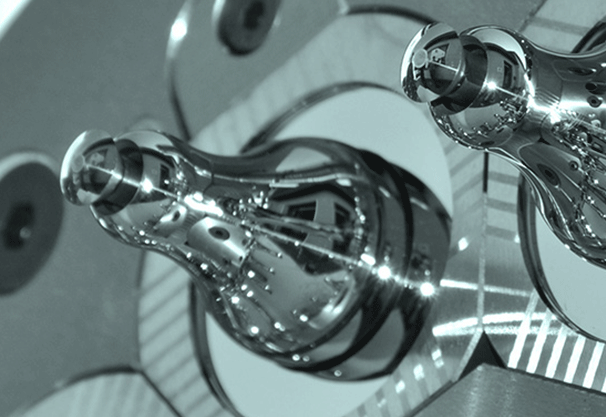

As mentioned earlier, precision mould is used for the development of various products. But this technology has really revolutionized the development of lenses in various applications because it allows OEM to manufacture cheaper and stronger glass-free lenses. Glass lenses are very delicate, difficult to manufacture, and expensive, but plastic optical lenses have completely changed the optical industry. Precision molding is used for the development and mass production of precision spherical, diffraction, free-form surface, aspheric, and other types of lenses. It is a high-quality product with a perfect optical surface finish.

Difference Between Precision Injection Molding and Ordinary Injection Molding

Packson, a top precision mould part manufacturer, specializes in both precision and ordinary injection molding.

Precision medical grade silicone injection molding, as the name suggests, requires high precision and surface quality of the molded parts. This process has special requirements for the injection molding machine, injection mold, molding process, and molding materials.

On the other hand, ordinary injection molding may not require the same level of precision or surface quality. The choice between precision molding and ordinary injection molding depends on the specific needs of the project.

At Packson, we deliver high-quality precision mould parts, meeting the exact specifications of our clients, regardless of the complexity of your project. Whether you need precision molding or ordinary injection molding, Packson has the expertise to deliver.

As a china injection moulding company, we will do our best to meet all the needs of customers.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Explore Packson's Injection Molding Services | With more than 20 years experience of injection molding industry and equipped with ISO Class 8 Clean Room, as the injection moulding products manuf... | |

| Silicone Rubber Injection Molding | Silicone rubber injection molding has more than a half-century history since the late 1970s. There are two molding ways of silicone rubber injectio... | |

| Precision Injection Molding | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that meet or exceed international quality standards, inclu... | |

| Clean Room Injection | With more than 20 years of experience in clean room injection molding, as the medical silicone molding companyin China, we specialize in various cl... | |

| Overmolding Injection Molding | Overmolding mold is made of overmolding injection molding process which is a special injection molding process that can combine various materials i... |

Похожие товары

| JY-160S2 Standard Plastic Injection Machine | Продавец: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | Продавец: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Продавец: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Продавец: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Продавец: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |